3A-13

90-13645--2

495

FUEL SYSTEM AND CARBURETION

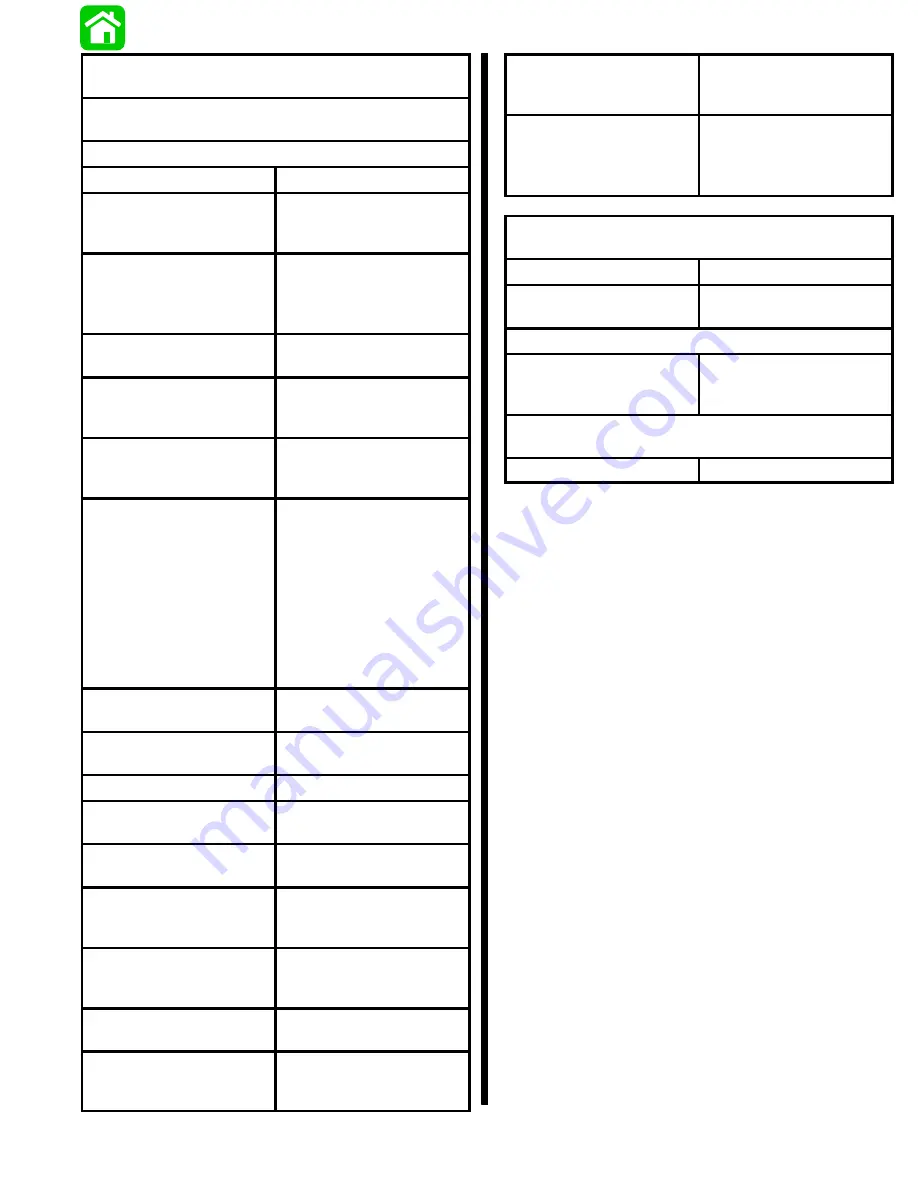

PROBLEM 1: ENGINE IDLES ROUGH AND

STALLS

PROBLEM 2: ENGINE RUNS UNEVEN OR

SURGES

PROBLEM 3: ENGINE WILL NOT ACCELERATE

Possible Cause

Corrective Action

Fuel tank air vent closed

or restricted.

Check - Air vent must

be open all-the-way and

free from restrictions.

A pinched, cut or

restricted fuel line; also

loose fuel line

connection.

Check all fuel lines and

replace as needed.

Check and tighten all

fuel line connections.

A dirty or restricted fuel

filter.

Check, replace, or clean

all fuel filters.

Restricted filter in fuel

tank.

Clean by rinsing in

clean lead-free gasoline

or kerosene.

Improperly mixed fuel;

contaminants (water,

dirt, etc.) in fuel.

Check fuel and replace,

if necessary.

An inlet needle (in

carburetor) that is either

stuck open or closed. (A

needle, that is stuck

open, will cause a

flooding condition. A

needle, that is stuck

closed, will prevent fuel

from entering

carburetor.)

Remove and replace

with new inlet needle.

Incorrect idle mixture

adjustment.

Re-adjust.

Damaged fuel pump

diaphragm.

Replace.

Carburetor is loose.

Tighten bolts securely.

Chamber cover leaking

air.

Tighten or replace

gasket.

Off idle holes plugged.

Blow out with

compressed air.

Main nozzle or idle

nozzle air bleed holes

plugged.

Blow out with

compressed air.

Improper main jet or

restricted jet.

Clean or replace with

proper jet (refer to “Main

Jet Chart”).

Damaged reed(s).

Inspect reeds as

outlined in Section 4A.

A crack in the fuel

pick-up outlet tube

(located in fuel tank).

Replace.

A crack in the fuel outlet

tube (located in fuel

tank.)

Replace.

Anti-Siphon valve

restricting fuel flow.

Refer to “Checking for

Restricted Fuel Flow

Caused by Anti-Siphon

Valves,” following.

PROBLEM: FUEL BLOW-BACK OUT OF

CARBURETOR

Possible Cause

Corrective Action

Chipped/Broken

(reed-block) Reeds

Replace Reeds.

PROBLEM: ROUGH IDLE

If related to reed-block,

indicates excessive

preload in reeds.

Replace Reeds.

PROBLEM: CAN’T REDUCE ENGINE RPM TO

SLOW IDLE

Multiple Chipped Reeds.

Replace Reeds.

Checking for Restricted Fuel Flow

Caused by Anti-Siphon Valves

While anti-siphon valves are helpful from a safety

standpoint, they clog, they may be too small, or they

may have too heavy a spring. The pressure drop

across these valves can, create operational problems

and/or powerhead damage by restricting fuel. Some

symptoms of restricted (lean) fuel flow, are:

1. Loss of fuel pump pressure

2. Loss of power

3. High speed surging

4. Preignition/detonation (piston dome erosion)

5. Outboard cuts out or hesitates upon acceleration

6. Outboard runs rough

7. Outboard quits and cannot be restarted

8. Outboard will not start

9. Vapor lock

Any type of anti-siphon device must be located be-

tween the outboard fuel inlet and fuel tank outlet. A

method of checking [if such a device (or bad fuel) is

a problem source] is to operate the outboard with a

separate fuel supply which is known to be good.

If, it is found that the anti-siphon valve is the cause of

the problem, either 1) replace the anti-siphon valve or

2) replace it with a solenoid-operated fuel shutoff

valve.

Содержание 100

Страница 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Страница 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Страница 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Страница 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Страница 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Страница 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Страница 118: ...OIL INJECTION SYSTEM B 3 ...

Страница 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Страница 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Страница 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Страница 205: ...MID SECTION LOWER UNIT B 5 ...

Страница 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Страница 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Страница 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Страница 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Страница 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Страница 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Страница 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Страница 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Страница 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Страница 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...