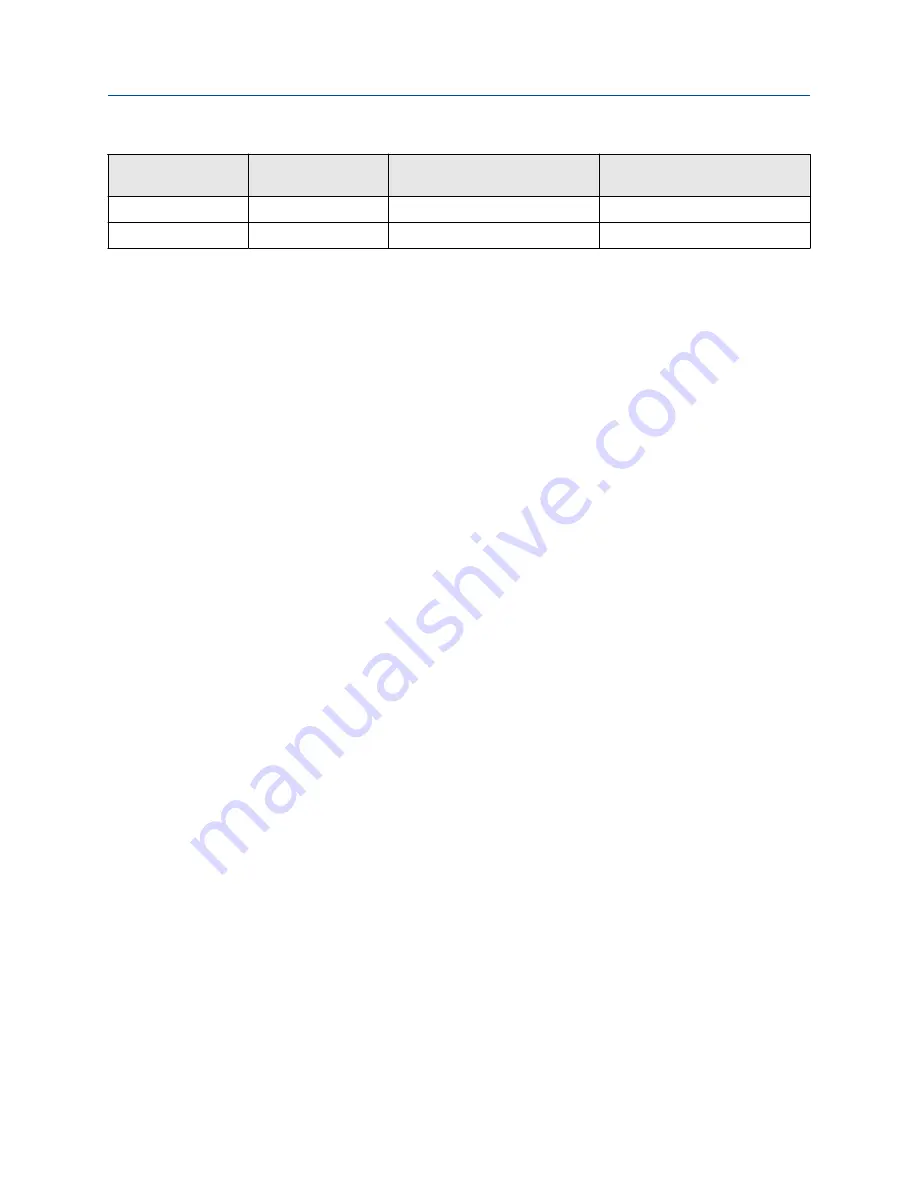

Terminal pair

(transmitter)

Terminal pair (core

processor)

Function

Expected resistance

Black – white

2–3

VDC– and RS-485/A

29 kΩ to 33 kΩ

Black – green

2–4

VDC– and RS-485/B

16 kΩ to 18 kΩ

6. If any resistance measurements are lower than specified, contact customer service.

7. If the resistance measurements fall within the expected ranges, return the transmitter to normal

operation and check the wiring between the transmitter and the core processor. If that does not

resolve the problem, contact customer service.

Postrequisites

To return to normal operation:

1. Reconnect the 4-wire cable from the sensor to the core processor terminals.

2. Replace the junction box cover.

3. Restore power to the transmitter.

17.15 Check batch total against scale reading

You can determine the accuracy of the batch process by comparing batch total as measured by the

transmitter to the batch total as measured by a scale.

Prerequisites

You mut be able to measure the delivered batch, using a highly accurate scale.

Procedure

1. Run a batch in the normal manner, using your current configuration.

2. Record the batch total as measured by the transmitter.

3. Measure the delivered batch on the scale and compare the two measurements.

4. If the transmitter's total does not match the scale reading:

a) Verify the zero, and perform a zero calibration if the zero verification does not succeed.

b) Check for two-phase flow.

c) Reduce the turndown across the sensor.

d) Set

Mass Flow Cutoff

(if you are batching by mass) or

Volume Flow Cutoff

(if you are batching

by volume) to a lower value.

5. If the problem is not resolved:

a) Decrease the flow rate and repeat the test.

b) Set the batch target to a higher value and repeat the test.

c) Perform the test on water.

If the results match when the process fluid is water, examine your process for sources of

inconsistency and instability.

Configuration and Use Manual

Troubleshooting

MMI-20025166

March 2019

Configuration and Use Manual

285