General Lubrication Information

Lubrication is an essential part of Preventive Maintenance, affecting to a great extent the

useful life of the compressor. Different Lubricants are needed and some components require

more frequent Lubrication than others. Therefore, it is important that the instructions

regarding types of Lubricants and the frequency of their application be explicitly followed.

Periodic Lubrication of the Moving Parts reduces to a minimum the possibility of mechanical

failures.

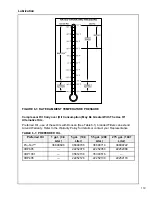

The

Maintenance Schedule

shows those items requiring regular service and the interval

in which they should be performed. A regular service program should be developed to

include all items and fluids. These intervals are based on average operating conditions. In

the event of extremely severe (hot, cold, dusty, or wet) operating conditions, more frequent

lubrication than specified may be necessary.

All filters and filter elements for air and compressor oil must be obtained through portable

power to ensure the proper size and filtration for the compressor.

Compressor Oil Change

High Pressure Air Can Cause Severe Injury Or Death From Hot Oil And

Flying Parts. Always Relieve Pressure Before Removing Caps, Plugs,

Covers, Or Other Parts From Pressurized Air System. Ensure That The

Air Pressure Gauge Reads Zero (0) Pressure And Ensure There Is No Air

Discharge When Opening The Manual Blowdown Valve.

In Most Severe Applications (I.E., Sandblasting, Quarry Drilling, Well

Drilling, And Oil And Gas Drilling) More Frequent Service Intervals Will

Be Required To Ensure Long Component Life.

Some Oil Types Are Incompatible When Mixed And Result In The

Formation Of Varnishes, Shellacs, Or Lacquers Which May Be Insoluble.

Such Deposits Can Cause Serious Troubles Including Clogging Of The

Filters. Do Not Mix Oils Of Different Types And Avoid Mixing Different

Brands. A Type Or Brand Change Is Best Made At The Time Of A

Complete Oil Drain And Refill.

116

Содержание P185WDOU-T4F (F89)

Страница 2: ......

Страница 3: ...iii...

Страница 4: ......

Страница 10: ...10...

Страница 11: ...Foreword 11...

Страница 14: ...14...

Страница 15: ...Safety 15...

Страница 32: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 32...

Страница 33: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 33...

Страница 34: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 34...

Страница 35: ...Safety Safety Symbols Below is summary of the intended meanings for the symbols used on safety compressor 35...

Страница 37: ...Lifting Transporting and Preparation 37...

Страница 46: ...46...

Страница 47: ...Noise Emission 47...

Страница 53: ...General Data 53...

Страница 57: ...Operating Instructions 57...

Страница 77: ...Engine Operation 77...

Страница 102: ...Engine Operation Step 4 Drain Engine Oil Showing engine drain location FIGURE 4 4 SHOWING ENGINE OIL DRAIN 102...

Страница 104: ...Engine Operation Step 5 Replacing Oil Filter Showing oil filter location FIGURE 4 5 REPLACING OIL FILTER 104...

Страница 115: ...Lubrication 115...

Страница 120: ...120...

Страница 121: ...Maintenance 121...

Страница 141: ...Troubleshooting 141...

Страница 150: ...150...

Страница 151: ...Compressor Diagnostic Codes 151...

Страница 156: ...156...

Страница 157: ...Engine Fault Codes 157...

Страница 158: ...Engine Fault Codes Engine Fault Code List 158...

Страница 159: ...Engine Fault Codes Engine Fault Code List 159...

Страница 160: ...Engine Fault Codes Engine Fault Code List 160...

Страница 161: ...Engine Fault Codes Engine Fault Code List 161...

Страница 162: ...Engine Fault Codes Engine Fault Code List 162...

Страница 163: ...Engine Fault Codes Engine Fault Code List 163...

Страница 164: ...Engine Fault Codes Engine Fault Code List 164...

Страница 165: ...Engine Fault Codes Engine Fault Code List 165...

Страница 166: ...Engine Fault Codes Engine Fault Code List 166...

Страница 167: ...Engine Fault Codes Engine Fault Code List 167...

Страница 168: ...Engine Fault Codes Engine Fault Code List 168...

Страница 169: ...Preventive Maintenance Schedule PMS 169...

Страница 170: ...Preventive Maintenance Schedule PMS Preventive Maintenance Schedule PMS Preventive Maintenance Schedule 170...

Страница 171: ...Torque Values 171...

Страница 175: ...Wiring Diagrams 175...

Страница 176: ...Compressor and Engine Harness 176...

Страница 177: ...177...

Страница 178: ...178...

Страница 179: ...179...

Страница 180: ...180...

Страница 181: ...Compressor and Engine Control System 181...

Страница 182: ...182...

Страница 183: ...183...

Страница 184: ...P185WDOU Generator Option 184...

Страница 185: ...185...

Страница 186: ...Electrical Parts List 186...

Страница 187: ...187...

Страница 188: ...INTENTIONALLY LEFT BLANK 188...

Страница 189: ...Warranty 189...

Страница 190: ...Warranty Warranty Doosan Portable Power General Warranty Information 190...

Страница 191: ...Warranty Truck Mounted Equipment 191...

Страница 192: ...Warranty Doosan Infracore Federal California Emission Control Systems Limited Warranty for Non Road Engines CI 192...

Страница 194: ......

Страница 195: ......