Chapter 16

16-26

T-16-39

<PANEL>

T-16-40

<Input Key Numbers and Names>

T-16-41

<PART-CHK>

T-16-42

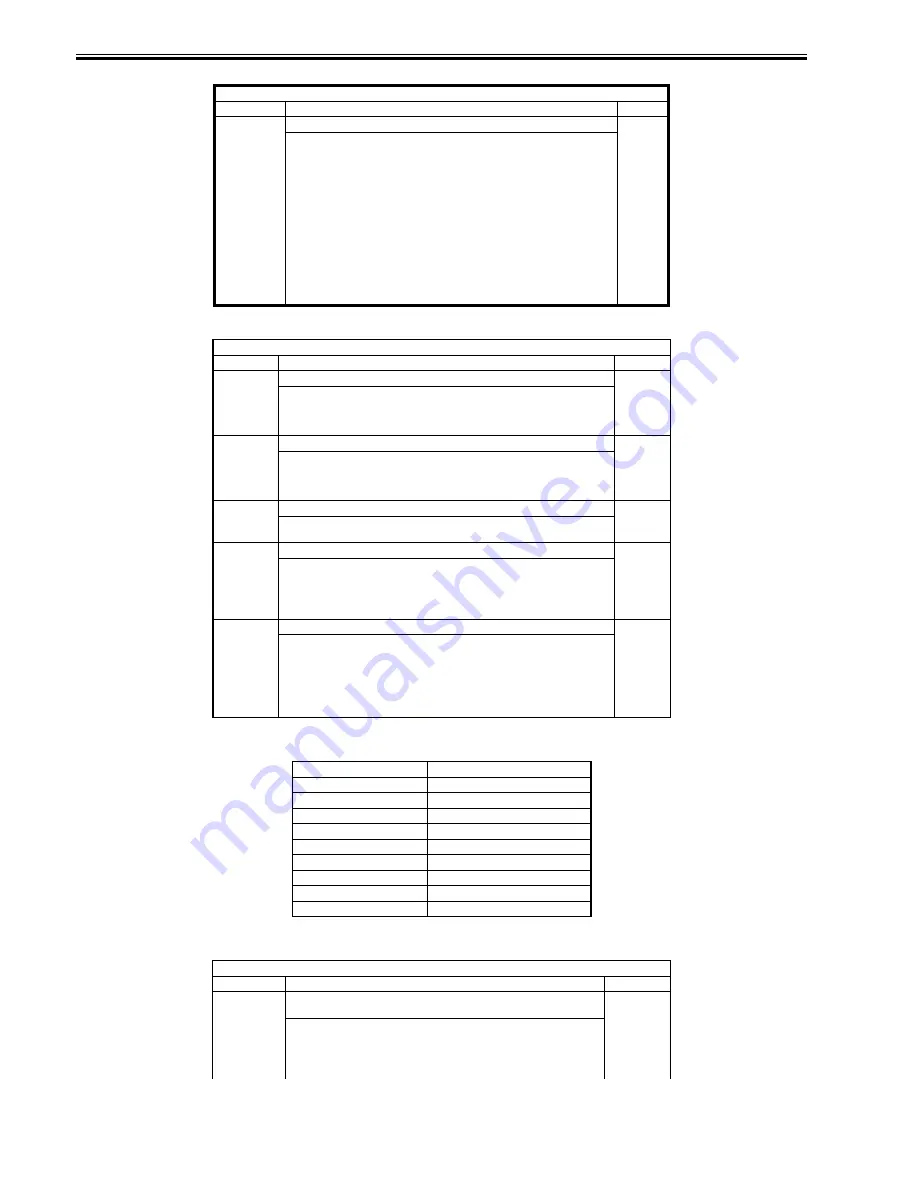

COPIER > FUNCTION > FIXING

Sub-item

Description

Level

NIP-CHK

Making output for measuring the fixing nip width automatically

1

<Operating procedure>

1) Make a solid black print in A4/LTR.

2) Make about 20 A4/LTR prints of the Test Sheet.

3) Place the A4/LTR solid black output obtained in step 1. in the manual feed tray

with the printed side facing down.

4) Select this service mode and press the OK key (to feed paper from the manual

feed tray).

5) The fed paper is held once by the fixing roller and ejected after about 10 seconds.

6) Check that the nip width of the ejected paper conforms to the standard.

<Standard>

iR4570/4570F/3570/3570F:7.6 to 10.6mm

iR2870/2870F/2270/2270F:4.0 to 6.0mm

<Note>

This machine does not allow nip width adjustment. This item is used for nip width

checking only.

COPIER > FUNCTION > PANEL

Sub-item

Description

Level

LCD-CHK

Checking the LCD display for missing dots

1

<Operating procedure>

1) Select this item and press the OK key to start operation. The front of the panel

lights repeatedly in order of white, black, red, green, and blue. (Check this lighting.)

2) Press the Stop key to terminate the operation.

LED-CHK

Checking LED lighting in the operating section

1

<Operating procedure>

1) Select this item and press the OK key to start operation. The LED lamps light

sequentially.

2) Press LED-OFF to terminate the operation.

LED-OFF

Checking LED lighting in the operating section

1

<Operating procedure>

1) Select this item to terminate LED-CHK operation.

KEY-CHK

Checking key input

1

<Operating procedure>

1) Select KEY-CHK to display the input key numbers and names.

2) Press a key to check. If the key is normal, the touchpanel displays the

corresponding key. (See the attached table.)

3) Select KEY-CHK again to exit from key input check.

TOUCHCHK Adjusting the coordinate positions on the analog touchpanel

1

<Operating procedure>

- Align the press positions on the touchpanel and the coordinate positions on the

LCD section.

- If the LCD section has been replaced, execute this service mode.

1) Select TOUCHCHK to reverse its display. Then press the OK key.

2) Press sequentially the nine positive signs (+) that appear on the touchpanel in

order.

Key

Screen Display

0 to 9, #, and *

0 to 9, #, and *

Reset

RESET

Stop

STOP

User Mode

USER

Start

START

Clear

CLEAR

PIN

ID

Help

?

Counter Check

BILL

COPIER > FUNCTION > PART-CHK

Sub-item

Description

Level

CL

Specifying a clutch to check its operation

(Range: 1 to 6)

1

<Operating procedure>

1) Select this item.

2) Enter the code of the clutch from the ten-key pad.

3) Press the OK key.

4) Press CL-ON to check its operation.

Содержание iR3570 Series

Страница 1: ...Jan 17 2007 Service Manual iR4570 3570 2870 2270 Series...

Страница 2: ......

Страница 6: ......

Страница 27: ...Chapter 1 Introduction...

Страница 28: ......

Страница 70: ......

Страница 71: ...Chapter 2 Installation...

Страница 72: ......

Страница 146: ......

Страница 147: ...Chapter 3 Basic Operation...

Страница 148: ......

Страница 150: ......

Страница 154: ......

Страница 155: ...Chapter 4 Main Controller...

Страница 156: ......

Страница 187: ...Chapter 5 Original Exposure System...

Страница 188: ......

Страница 217: ...Chapter 5 5 27 F 5 91...

Страница 218: ......

Страница 219: ...Chapter 6 Laser Exposure...

Страница 220: ......

Страница 222: ......

Страница 230: ......

Страница 231: ...Chapter 7 Image Formation...

Страница 232: ......

Страница 236: ......

Страница 279: ...Chapter 7 7 43 F 7 241 2 Remove the screw 1 F 7 242 3 Detach the static eliminator 1 to the front F 7 243...

Страница 280: ......

Страница 281: ...Chapter 8 Pickup Feeding System...

Страница 282: ......

Страница 388: ......

Страница 389: ...Chapter 9 Fixing System...

Страница 390: ......

Страница 419: ...Chapter 9 9 27 F 9 148...

Страница 420: ......

Страница 421: ...Chapter 10 External and Controls...

Страница 422: ......

Страница 426: ......

Страница 437: ...Chapter 10 10 11 F 10 12 2 Remove the check mark from SNMP Status Enabled...

Страница 438: ...Chapter 10 10 12 F 10 13...

Страница 440: ...Chapter 10 10 14 F 10 15...

Страница 475: ...Chapter 11 MEAP...

Страница 476: ......

Страница 478: ......

Страница 481: ...Chapter 12 Maintenance and Inspection...

Страница 482: ......

Страница 484: ......

Страница 509: ...Chapter 13 Standards and Adjustments...

Страница 510: ......

Страница 512: ......

Страница 521: ...Chapter 14 Correcting Faulty Images...

Страница 522: ......

Страница 528: ......

Страница 537: ...Chapter 14 14 9 43mm s b Z x i j B iR4570_395 s u A B FM2 0287...

Страница 538: ...Chapter 14 14 10...

Страница 539: ...Chapter 14 14 11...

Страница 585: ...Chapter 15 Self Diagnosis...

Страница 586: ......

Страница 588: ......

Страница 623: ...Chapter 16 Service Mode...

Страница 624: ......

Страница 626: ......

Страница 679: ...Chapter 17 Upgrading...

Страница 680: ......

Страница 682: ......

Страница 693: ...Chapter 17 17 11 F 17 18 2 Click Start F 17 19 3 When the session has ended click OK...

Страница 698: ...Chapter 17 17 16 F 17 28 2 Click Start F 17 29 3 When the session has ended click OK...

Страница 710: ...Chapter 17 17 28 F 17 51 3 Click Start F 17 52 4 Click Save...

Страница 712: ...Chapter 17 17 30 F 17 55 2 Select the data to download F 17 56 3 Click Start...

Страница 714: ......

Страница 715: ...Chapter 18 Service Tools...

Страница 716: ......

Страница 717: ...Contents Contents 18 1 Service Tools 18 1 18 1 1 Special Tools 18 1 18 1 2 Oils and Solvents 18 1...

Страница 718: ......

Страница 720: ......

Страница 721: ...Jan 17 2007...

Страница 722: ......