7.2 Installation Procedure

7.2.3 SGLT Servomotors (Models with T-type Iron Cores)

7-12

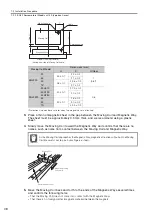

3.

Hold the provisionally mounted Magnetic Way yoke tightly against the positioning ridges

and secure it completely with screws.

Note:These values are for the following conditions.

•

Equipment materials: Iron

•

Use of socket head screws with a strength class of 10.9

4.

Remove the bolts from mounting spacers on the side of the Magnetic Way yoke that you

mounted.

5.

Hold the other Magnetic Way yoke tightly against the positioning ridges and secure it

completely with screws.

Note: Be careful not to let the Magnetic Way yoke slip in the direction of Moving Coil forward movement.

6.

Remove the mounting spacers. If there are Magnetic Way mounting holes in the posi-

tions where the mounting spacers were attached, secure the yokes with screws in those

mounting holes as well.

This concludes the procedure.

SGLTM-

AY

Use the following procedure.

1.

Place the base to which the Magnetic Way yokes are attached in the specific location in

the equipment.

2.

Firmly secure the base to the equipment with bolts using the base mounting bolt holes.

This concludes the procedure.

Magnetic Way Model

SGLTM-

Screw Nominal Size

Tightening Torque

(N

cm)

20

M6

1,220 to 1,710

35

50

40

M8

2,970 to 4,150

80

Hold the

Magnetic

Way yoke.

Positioning ridge