6.4 Precautions for Water-Cooled Models

6-7

6

E

q

uipment De

s

ign Pr

ecaution

s

6.4

Precautions for Water-Cooled Models

SGLFW2 Servomotors (SGLFW2-

A

L

) use forced cooling with a cooling medium.

Observe the following precautions if you use one of these Servomotors.

Cooling System Design and Installation

•

You must design, purchase, and install the portion of the cooling system that is external to

the Servomotor, such as the cooling medium, piping, and chiller or other cooling device.

•

The joints on the Servomotor are made of stainless steel. Use parts that will not corrode for

the connecting joints, piping, and other connecting parts. (We recommend that you use

stainless steel parts.)

•

The joints on the Servomotor are Rc1/8 (taper pipe thread). Wrap joints with sealing tape or

take other measures to prevent the cooling water from leaking.

•

Use flexible piping tubes to prevent leaking.

Cooling Medium

•

Use cooling water for the cooling medium.

•

Use cooling water that meets the water quality standards given in the following table (con-

forming to JRA GL-02 1994 of the Japan Refrigeration and Air Conditioning Industry Associ-

ation).

If the water quality standards are not met, cooling performance will suffer and corrosion may

cause problems.

•

The temperature range for the cooling medium supplied to the Servomotor is 5°C to 25°C.

Using a colder cooling medium will increase cooling performance, but make sure that freezing

or condensation does not occur.

•

The rated cooling medium flow rate is 4 L/min. This is the minimum flow rate required to pre-

vent burning in the Servomotor for the current flow that corresponds to the rated force.

If the flow rate is less than 4 L/min, install a protective circuit to cut off the current to the Ser-

vomotor.

•

The maximum cooling medium flow rate is 6 L/min.

•

Do not allow cooling water to be contaminated with oils, chemicals, or other impurities.

Preventing Contamination by Foreign Matter

Any foreign matter that is 0.5 mm or larger must not be allowed to enter the cooling piping to

the Servomotor. Install a strainer, filter, or similar device to remove such foreign matter from the

cooling water in the piping upstream from the cooling medium inlet port on the Servomotor.

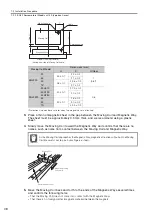

Item

Water Quality Standard (Makeup

Water Requirements for Cooling

Water)

pH (25°C)

6.8 to 8.0

Conductivity (mS/m) (25°C)

30 max.

Chloride ions (mgCl-/l)

50 max.

Sulfate ions (mgSO

4

2

-/l)

50 max.

Alkalinity (pH4.8) (mgCaCO

3

/l)

50 max.

Total hardness (mgCaCo

3

/l)

70 max.

Calcium hardness (mgCaCO

3

/l)

50 max.

Ionic silica (mgSiO

2

/l)

30 max.

Iron (mgFe/l)

0.3 max.

Copper (mgCu/l)

0.1 max.

Sulfide ions (mgS

2-

/l)

Must not be detected.

Ammonium ions (mgNH

4

+

/l)

0.1 max.

Residual chlorine (mgCl/l)

0.3 max.

Free carbon dioxide (mgCO

2

/l)

4.0 max.