3 System Startup

3.4.1 Program Outline

3-50

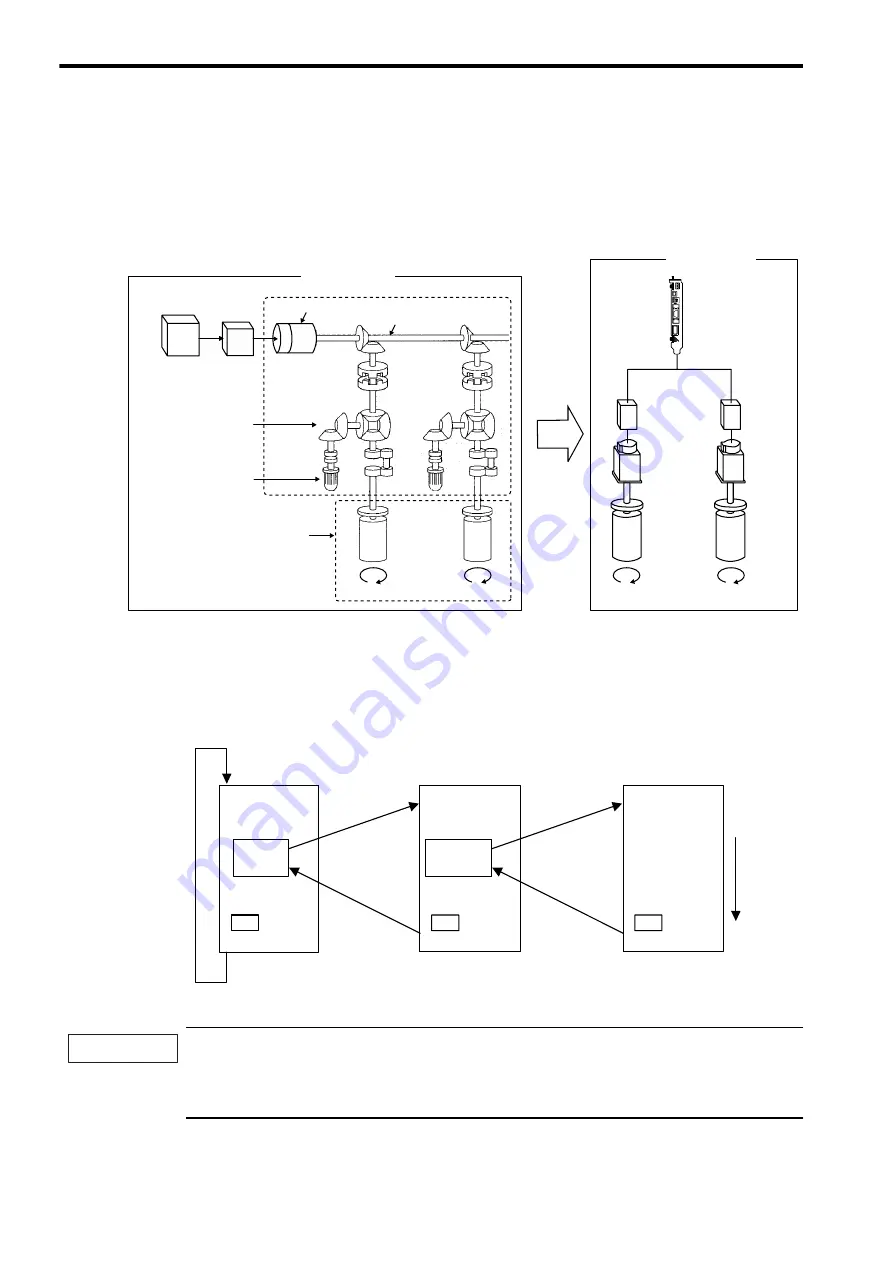

3.4 Sample Program 3: Phase Control with an Electronic Shaft

3.4.1 Program Outline

The same operation for the No. 1 and No. 2 rolls connected to the line shaft is performed using a Servomotor.

Phase synchronization, however, has not been used.

• The H06.01 drawing (ladder program) controls the operation.

• The two axes rotate synchronously according to the entered speed settings.

• The following gear ratio is set in this example.

Axis 1 (No. 1 roll): Axis 2 (No. 2 roll) = 1:1

Refer to

3.4.3 Program Details

for details on the sample program.

• This program is solely for the purpose of describing the MP2100 system startup. Care must be taken because

actual applications will differ.

• This system for the program has no power OFF circuit for the SERVOPACK in the event of emergency stops

or overtravel. Include a proper emergency stop circuit in actual applications.

MP2100

Servo-

motor

SERVOPACK

No.1

Controller

Driver

Phase sync device

Motor

Gear

Differential gear

Clutch

Working part

Line shaft

Line shaft drive motor

No.2 roll

roll

New method

Old method

END

END

END

Parent Drawing

H Drawing

H06 Drawing

Child Drawing

High-speed scan

H06.01 Drawing

Grandchild Drawing

Phase control

Electronic shaft

• Axis 1

• Axis 2

SEE

Name H06.01

SEE

Name H06

IMPORTANT