- 43 -

3. CONTROL SYSTEM

No.

37

[405]

38

[501]

39

45

[407]

60

65

70

[403]

Problem

Load handling contactor

(MP) shorted

Detection circuit harness

defective

Load handling contactor

(MP) drive Tr defective

(Tr 4 inside CPU board)

Load contactor coil stuck

open

Detection circuit harness

defective

Load handling controller

temperature abnormal

Load handling main fuse

(F2) blow out

Detection circuit harness

defective

Load handling controller

temperature rises

abnormally.

Load handling motor

temperature abnormal

(external input signal)

Load handling quick

charge function defective

(Capacitor on load

handling capacitor board

is not properly charged.)

Error

Load handling system

does not work.

Load handling system

does not work.

Load handling system

does not work.

(The error is detected

when the temperature is

115°C and load handling

system does not work.)

Load handling system

does not work.

(MP contactor does not

close.)

Load handling system

works.

(This error is detected

when the temperature

exceeds 110°C, and

the conduction ratio is

restricted.)

Load handling system

does not work.

Usual load handling

operation is possible

(This error is detected

when the error code 30

occurs.)

Contactor ON timing is

late.

Remedy

Proceed with remedy in numerical order of encircled numbers.

①

Check load handling contactor (MP), and repair

or change if needed.

(seized contact points or mechanical hitch)

②

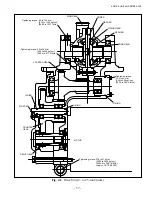

Check harness between CN5-22 (CPU board)

and P11 terminal, and repair or change if needed.

③

Check harness between CN4-10 (CPU board)

and P13 terminal, and repair or change if needed.

①

Check thermo sensor (THP) voltage, and change

if needed.

Check load handling contactor (MP) coil

connectors for disconnection and coil for

breakage, and repair or change if needed.

②

Check harness between contactor coil connector

and CN4-5, 13 (CPU board), and repair or

change if needed.

③

Change CPU board (drive Tr defective).

①

Cool down the controller.

②

Check TMP for loose fitting screws.

③

Check the resistance/voltage of thermo sensor

(THP), and change if needed.

④

Check harness between CN7-6, 12 (CPU board)

and thermo sensor (THP), and repair or change if

needed.

⑤

Check harness between CN9-6 (CPU board) and

CN1R-6, and repair or change if needed.

①

Check load handling fuse (F2), and change if

needed.

②

Check harness between CN5-22 (CPU board)

and P11 terminal, and repair or change if needed.

③

Check harness between CN4-8 (CPU board) and

P1 terminal, and repair or change if needed.

①

Cool down the controller.

②

Check TMP for loose fitting screw.

③

Check the resistance/voltage of thermo sensor

(THP).

④

Check harness between CN7-6, 12 (CPU board)

and thermo sensor (THP), and repair or change if

needed.

⑤

Check harness between CN9-6 (CPU board) and

CN1R-6, and repair or change if needed.

①

Cool down load handling motor.

②

Check the harness of CN1-22 (CPU board).

①

When the load handling system does not work,

check the error code 30 first.

②

Change CPU board (quick charge drive Tr, poor

resistance).

Reset

Turn off

key switch.

Turn off

key switch.

Restore

to normal

when the

temperature

drops below

115°C.

Turn off

key switch.

Restores

to normal

when the

temperature

drops below

100°C.

Restore to

normal.

Turn off

key switch.

Remarks

Thermo sensor (THP)

voltage under normal

condition:

0.2 V to 4.95 V

The resistance/voltage

of thermo sensor under

normal condition

20 k

Ω

/4.0 V (±10%) at

25°C.

Check for secondary

voltage of fuse (F2).

Thermo sensor (TH)

voltage under normal

condition:

0.1 V to 4.95 V

The resistance/voltage

of thermo sensor under

normal condition:

20 k

Ω

/4.0 V (±10%) at

25°C.

The error is detected when

the PM thermo switch is

opened (more than 120°C

and released when the

temperature drops (switch

closed).

If the key switch is

turned on with capacitor

improperly charged, the

contactor timing becomes

late. In addition, an arc

occurs when the contactor

is turned on, to promote

the wear of contactor.

Numbers in brackets are error codes that appear on the meter panel.

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...