7. HYDRAULIC SYSTEM

- 107 -

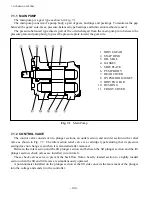

(2) Oil pressure adjustment

①

Remove the plug of the check port (G) located in the inlet section of the control valve, then set there

a 20 MPa {200 kgf/cm

2

} [2901 psi] capacity oil pressure gauge.

②

Operate the tilt lever till the cylinder piston reaches it stroke end. Then measure the hydraulic

pressure at that position.

③

If the pressure is not as specified, loosen the relief valve lock nut and adjust it by turning the

adjustment. If the measured pressure is higher than the specified, once lower it by turning the

adjustment screw counterclockwise till it goes down below the specifi ed level. Then turn the screw

clockwise this time till the specifi ed level is acquired.

④

When adjustment is complete, tighten the lock nut.

Fig. 7.4

INLET SECTION

RELIEF VALVE

LOCK NUT

CAP

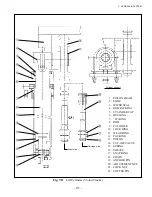

Unit: MPa {kgf/cm

2

} [psi]

1 to 1.8 t

2.0 to 3.5 t

Required oil pressure

14.2 {145} [2062]

17.2 {175} [2489]

•

•

•

•

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...