5. BRAKE SYSTEM

- 66 -

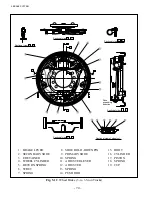

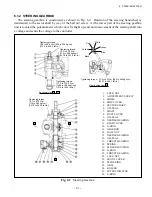

(1) Wheel brake operation

The wheel cylinder pushes the primary and

secondary shoes against the brake drum with an

equal force. The shoes are kept turning with the

brake drum until the top of the secondary shoe comes

in contact with the anchor pin.

When the secondary shoe comes in contact

with the anchor pin, the friction force is generated

between the brake lining and the brake drum, and

the primary shoe pushes the secondary shoe with a

stronger force than the operation force of the wheel

cylinder. Powerful braking force is thus achieved.

(See Fig. 5.4)

In backward travel, the braking force works in the

reverse direction of forward travel. (See Fig. 5.5)

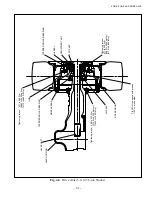

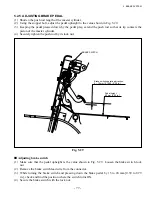

(2) Parking brake

The parking brake unit is built in the wheel brake,

and consists of a lever and strut.

The lever is installed on the primary shoe side

with a pin. Movement of the lever is also transmitted

to the secondary shoe side through the strut.

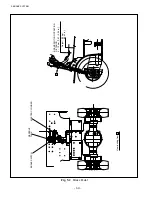

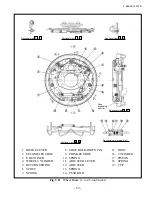

5.1.3 WHEEL BRAKE

The wheel brake is duo-servo type, and is mounted

on each of the both ends of the drive axle.

The wheel brake is composed of two pairs of

brake shoes, a wheel cylinder and adjuster.

One end of the brake shoe is contacted with the

anchor pin and another end is contacted with the

adjuster. The brake shoes are pushed against the

backing plate through the shoe hold-down spring and

shoe hold-down pin.

The parking brake mechanism and the automatic

clearance adjuster are also built in the wheel brake.

Fig. 5.6

Parking Brake

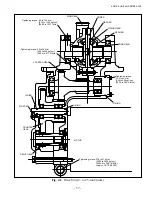

Fig. 5.4

Braking Operation in Forward Travel

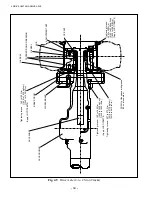

Fig. 5.5

Braking Operation in Backward Travel

ADJUSTER

PRIMARY SHOE

Rotation direction of

drum

ANCHOR PIN

PIN

LEVER

SECONDARY SHOE

STRUT

Working force

Secondary

Primary

Working force

Secondary

Primary

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...