3. CONTROL SYSTEM

- 52 -

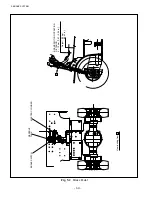

6. Checking PS transistors (TMPS1, TMPS2)

The PS drive transistors are two IGBT modules which form an H bridge.

①

Visually check the transistors for scores, scratches, damage, or excessive discoloration.

②

Remove all the cables from the module you are going to check, and measure the resistance between

terminals using the tester according to the table given below.

Use an analog tester set to a resistance range of 100

Ω

.

③

Judge whether the transistor is good or defective using the measured values.

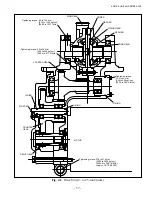

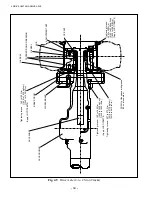

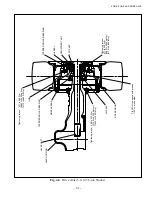

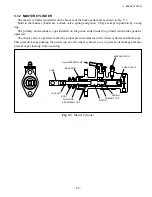

7. Checking traveling/load handling/PS contactors (MD, MP, MPS)

(1) Checking mechanical movement of contactors

①

Inspection should be performed on each

contactor removed from the truck.

②

Push the movable contact with hand to conduct,

and check if it functions smoothly.

③

Push further after contacts are closed to check if

the compression spring is properly compressed

to press the contacts.

④

If any defect is found throughout the above

steps, replace the contactor with a new one.

Caution: Before installing an IGBT module,

apply silicone compound (Shietsu

Silicone G746 or equivalent) at the

rear side of the module.

ARMATURE

COIL

CONNECTOR

“a”

CONTACT

MOVABLE

CONTACT

COMPRESSION

SPRING

Location

Tester

Normal value Judgment

(+)

(–)

Rough guide

Good

Not good

G1-C1

G1

C1

∞ Ω

∞ Ω

other than

∞ Ω

C1

G1

∞ Ω

∞ Ω

other than

∞ Ω

G1-E1

G1

E1

∞ Ω

∞ Ω

other than

∞ Ω

E1

G1

∞ Ω

∞ Ω

other than

∞ Ω

C1-E1

C1

E1

∞ Ω

∞ Ω

other than

∞ Ω

E1

C1

approx. 700

Ω

more than 1

Ω

0

Ω

and

∞ Ω

G2-C2

G2

C2

∞ Ω

∞ Ω

other than

∞ Ω

C2

G2

∞ Ω

∞ Ω

other than

∞ Ω

G2-E2

G2

E2

∞ Ω

∞ Ω

other than

∞ Ω

E2

G2

∞ Ω

∞ Ω

other than

∞ Ω

C2-E2

C2

E2

∞ Ω

∞ Ω

other than

∞ Ω

E2

C2

approx. 700

Ω

more than 1

Ω

0

Ω

and

∞ Ω

* The values given above should be used as rough guides. They will vary with different types of tester and the

internal battery’s state of charge.

Fig. 3.11

IGBT module

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...