2. MOTORS

- 23 -

(2) Check the following items with the motor stopped

Check item

Tightened areas

Terminals

Location

Screws and

nuts

Connections

Lead wires

Criteria

No looseness, adherence of dust, or corrosion

allowed.

Check visually and by tapping.

Connections are correct and not loose.

Proper insulation is ensured.

Visual check.

No damage to coating allowed.

Visual check.

Remedy

Retighten, clean or

paint.

Retighten.

Check for insulation.

Ask specialist for

repair.

2.2 MAINTENANCE

2.2.1 DRIVE MOTOR

(1) Check the following points with the motor running

Remedy

If too much deposit of

dust is found, stop the

motor and clean.

Return to normal

condition.

Return to normal

condition.

If allowable limit is

exceeded, stop the

motor and remove the

cause.

If any defect is found,

stop the motor and

remove the cause.

Check item

Dust

Foreign

matter,

splash, liquid

Temperature rise

Vibration

Noise

Location

Motor frame

Motor frame

Motor frame,

bearing

Motor frame,

bearing, and

cover

Motor frame,

bearing, cover

Criteria

No remarkable deposit of dust allowed

compared with usual operation.

Usual temperature rise.

Visual check.

No remarkable change allowed compared with

usual operation.

Visual check.

No remarkable rise in temperature allowed

compared with usual operation.

Temperature is below specified values:

Motor frame: 80°C [176°F]

Bearing: 55°C [131°F]

No remarkable vibration or amplitude increase

allowed compared with usual operation.

Visual and audible checks.

No remarkable noise or sound allowed compared

with usual operation.

Using a sound-check rod, check against new

product.

Audible check.

Environment

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

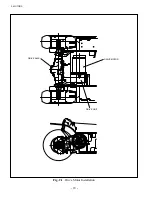

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

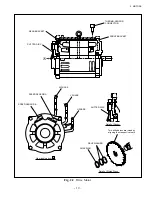

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

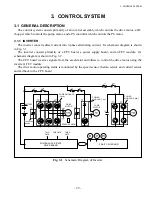

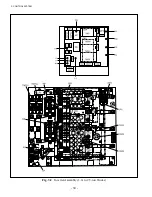

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...