1. BATTERY AND CHARGER

- 13 -

1.1.3 CHARGING PROCEDURES

(1) Normal charge

①

Turn off the key switch and apply the parking brake.

②

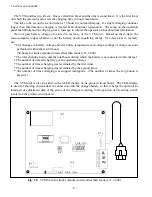

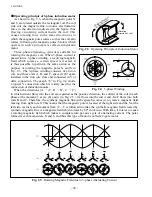

Make sure that the power supply at the facility side is off and insert the plug into the receptacle at

the truck side.

The plug at the truck side is a locking type. Insert the plug securely until it reaches the locked

position. Then, insert the plug into the receptacle at the facility side when it is equipped with the

power service outlet.

③

When the power supply at the facility side is turned on and the START button at the charging

operation panel is pressed, the CHARGING lamp lights up and the charging is started. Then, the

humming is heard from the transformer, which shows that the charger is operating. The charging

state is also displayed on the meter panel.

Note:

If the battery is not connected or the power supply at the facility side is 0-volt, the charging

operation cannot be started.

④

The charging is automatically terminated after it continues for 8 to 10 hours (the charging time

varies with the amount of discharge). The battery is not so exhausted, the charging may continue

for a short time (a few minutes).

Note:

If power failure occurs during charging and is remedied within 120 hours, battery charging

is automatically started again.

⑤

Make sure that the CHARGING lamp is turned off, turn off the power supply at the facility side.

Remove the plug at the truck side with its lock lever pressed.

⑥

After charging is finished, measure the specified gravity of the battery electrolyte to check if the

proper charging is carried out.

(2) Boosting charge

If the residual level gauge of the meter panel is probable to indicate level 3 or less after completing

the day’s work, it is recommended that boosting charge is carried out by using a rest period.

The starting procedure of the boosting charge is same as that of the normal charge, but be sure to

press the STOP button when terminating the boosting charge.

(3) Equalizing charge

Normally the battery does not need equalizing charge because when the battery needs it, the

microcomputer detects it and automatically puts the charger in equalizing charge operation. However,

manual equalizing charge is needed if:

•

Purified water is added to the battery electrolyte

•

The difference of the specific gravity in each cell is 0.02 or more.

•

Overdischarge more than 100% occurs.

The procedure for carrying out the equalizing charge is as follows:

①

Press the SUPER EQUALIZE button after taking the same steps as needed for normal charge, so

that the CHARGING lamp and SUPER EQUALIZE lamp light up.

②

When equalizing charge is automatically terminated (the CHARGING lamp goes out), the “SUPER

EQUALIZE” lamp is turned off and equalizing charge is released by pressing the “SUPER

EQUALIZE” button or turning the key switch on.

While the battery is charged, equalizing charge can be released by pressing the STOP button.

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

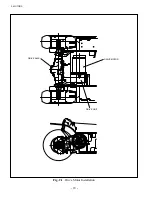

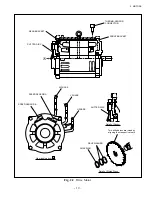

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...