- 51 -

3. CONTROL SYSTEM

(3) Checking PS fuse (F3)

①

Set the tester to the voltage measurement range and attach the negative pole of the tester to the

negative cable connection terminal of the controller.

②

Attach the positive pole of the tester to the upper terminal of the F3 fuse and then to the lower

terminal to measure the voltage at each terminal.

Voltage table (key switch turned ON)

Location

Voltage value

Judgment

Upper terminal

Battery

voltage

Good

0 V

Defective (change fuse)

Lower terminal

Battery voltage

Good

5. Checking current sensors

The current sensors detect the traveling U-phase

current, traveling W-phase current, and load handling

current and generate a voltage in proportion to each

electric current.

Before performing the following inspection,

visually check the sensors for scores, scratches,

damage or excessive discoloration. Do not touch the

current sensor VR.

(1) Checking traveling current sensors (CSDU, CSDW)

①

Set the tester to the voltage measurement range and attach the negative pole of the tester to the

negative cable connection terminal of the controller.

②

Attach the positive pole of the tester to each of the pins (3, 4, 5, 6, 14, 15, 16, and 17) of the CN5

(22-pin connector), and turn on the key switch to measure the voltage.

Voltage table (key switch turned ON)

Location

Normal

Measurement condition

Pin No.

Cable color

voltage value

CN5-3

R-B (red - black)

15

V

CN5-5

15

V

CN5-14

CN5-15 GR

(gray)

0

V

CN5-16

CN5-17

CN5-4 (CSDU)

O (orange)

7 V (0 A)

F/R lever in neutral, accelerator OFF.

The voltage will vary within the range of 3 V - 11 V during traveling.

CN5-6 (CSDW)

P (pink)

7 V (0 A)

F/R lever in neutral; accelerator OFF.

The voltage will vary within the range of 3 V - 11 V during traveling.

(2) Checking load handling sensor (CSP)

①

Set the tester to the voltage measurement range and attach the negative pole of the tester to the

negative cable connection terminal of the controller.

②

Attach the positive pole of the tester to each of the pins (7, 8, 18, and 19) of the CN5 (22-pin

connector), and turn on the key switch to measure the voltage.

Voltage table (key switch turned ON)

Location

Normal

Measurement condition

Pin No.

Cable color

voltage value

CN5-7

R-B (red - black)

15 V

CN5-18

GR (gray)

0 V

CN5-19

F/R lever in neutral.

CN5-8

W (white)

7 V (0 A)

The voltage will varies within the range of 7 - 9.35 V while the load

handling lever is actuated.

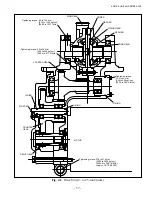

Fig. 3.10

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

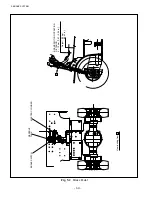

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

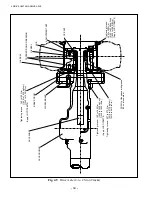

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

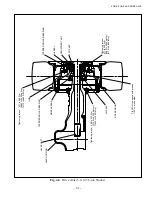

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...