2. MOTORS

- 28 -

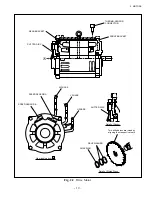

(4) Checking the commutator

The commutator is the most important part of the motor. If operated with oil or dust sticking to it,

the brush will be abnormally worn and commutator operation will be disabled. Keep it always clean by

removing such foreign matters by air blow or by wiping with dry, clean cloth.

If the surface of the commutator gets rough, polish it with sandpaper #500 or #600, then thoroughly

clean the commutator. If it gets too rough, it needs to be repaired by cutting.

If it is cut, the depth of the segment mica should also be corrected.

Finish the depth of the mica to 0.8 to 1.0 mm [0.0315 – 0.0394 in] measured from the surface of the

commutator for both the pump motor and drive motor.

Repairing the commutator requires special machine tools. Ask a specialized shop for repairing it.

■

Standard service data

Unit: mm [in]

Standard value

Standard length

27 [1.06]

Brush

Residual length

13 [0.51]

Spring force N {kgf}[lbf]

13 {1.33} [2.92]

O.D.

85 [3.35]

Commutator

Repair limit

82 [3.23]

Mica depth

0.7 - 1.0 [0.028 - 0.039]

Depth limit

0.2 [0.0079]

Shaft thrust

Standard

1.0 [0.039]

Limit

1.8 [0.071]

Bearing grease

Brand name

Multemp SRL

Coil resistance (

Ω

)

Armature

0.0173

Field

0.0106

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

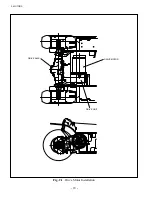

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

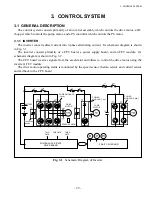

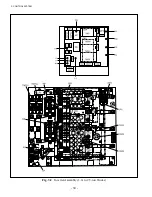

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...