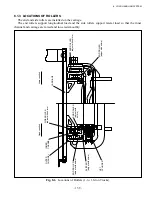

7. HYDRAULIC SYSTEM

- 130 -

7.2.2 TRIAL RUN

Trial runs should be performed to run in an assembled pump and to ensure that it delivers the

specified performance. Trial runs are preferably carried on a special test stand, but may be carried out

with the pump on the machine using the following manner:

(If the pump were disassembled because of a seized pump or an abnormally worn internal component,

be sure to change the hydraulic oil and replace the filters with new ones before trying to make a trial

run.)

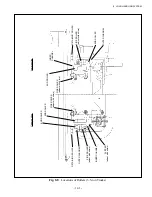

(a) Install the pump on the truck. Install a pressure gauge on the oil pressure check port of the control

valve.

(b) Loosen the relief valve adjustment screw and operate the pump at 500 to 1000 rpm for about 10

minutes. Make sure the pressure is less than 0.98 MPa {10 kgf/cm

2

} [142 psi].

(c) Increase the pump speed to 1500 to 2000 rpm and let the pump operate for about 10 minutes.

(d) Keeping the pump speed at 1500 to 2000 rpm, increase the pressure by 2 - 3 MPa {20 to 30 kgf/

cm

2

} [284 to 427 psi] up to 17.2 MPa {175 kgf/cm

2

} [2489 psi], letting the pump operate at each

pressure for about 5 minutes. Operate each circuit for 5 minutes and replace the return filter with a

new one.

While increasing the pressure, check the oil temperature and pump surface temperature. Check also

for operating noise. If the oil temperature or pump surface temperature rises excessively, reduce the

load and drop the temperature before continuing the test.

(e) After the test is over, set the oil pressure for 17.2 MPa {175 kgf/cm

2

} [2489 psi], perform a

discharge test. The pump discharge is checked by observing the lift speed.

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...