4. DRIVE UNIT AND DRIVE AXLE

- 62 -

■

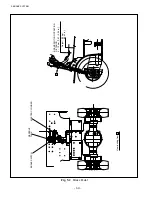

Procedure for installing the wheel hub

(1) Put the specified amount of grease into the

space

A

of the wheel hub and install it onto the

spindle.

(2) Tighten the adjustment nut to approx. 98 N-m {1

kgf-m} [7.23 lbf-ft] torque and loosen it by 1/2

turn.

(3) Set the spring balancer to the stud bolt. Adjust

the starting torque of the hub while tightening

the adjustment nut gradually.

Starting torque: 4.9 to 6.9 N-m

{50 to 70 kgf-cm}

[43.4 to 61.1 lbf-in.]

(4) Install the lock washers and the lock nuts, and

secure the lock nuts with the claws of the lock

washers.

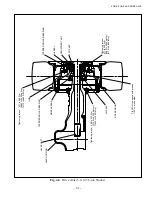

LOCK NUT

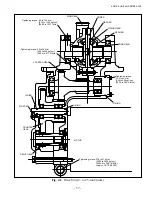

Fig. 4.7

Filling Grease

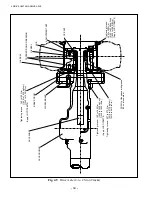

Fig. 4.8

Measuring Starting Torque

ADJUSTMENT NUT

LOCK WASHER

A

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...