33

Electronic expansion valve

EXV-B

●

●

Step from 0 to 480. Controlled according to discharge

temperature superheat.

Electronic expansion valve

EXV-C

●

●

Enhanced vapor injection EXV, Step from 0 to 480.

Controlled according to temperature difference

between economizer plate heat exchanger inlet and

outlet.

Four-way valve

ST1

●

●

Closed

Solenoid valve (defrost)

SV5

●

●

Closed

Solenoid valve (by pass)

SV6

●

●

Closed

Solenoid valve (injection)

SV8A/B

●

●

Open

Water side heat exchanger

heater

-

●

●

According to water side heat exchanger anti-freezing

temperature

Water flow switch

Water-SW

●

●

After water pump (field supplied) is turned on for

2min, if water flow switch is open, water pump stops

and water flow error code appears. The compressor

can be started after the water flow is normal.

Water flow switch heater

-

●

●

Controlled according to ambient temperature, water

inlet temperature and water outlet temperature

Crank case heater

CCH

●

●

Controlled according to ambient temperature and

discharge temperature

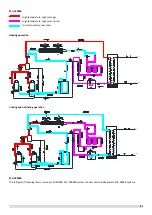

For SCV-1800EB:

Component

Wiring diagram label

180kW

Control functions and states

Inverter compressor

BP1/2

●

Controlled according to load requirement from hydronic system.

DC fan motor

FAN

●

Controlled according to outdoor heat exchanger pipe temperature.

Electronic expansion valve

EXV

●

Position (steps) from 0 (fully closed) to 480 (fully open), controlled

according

to

outdoor

ambient

temperature,

discharge

temperature, suction superheat, compressor speed and refrigerant

system pressure.

Four-way valve

ST1

●

Off

5.3

Compressor Output Control

The compressor rotation speed is controlled according to the load requirement. Before compressor startup, the outdoor unit

determines the compressor target speed according to outdoor ambient temperature, discharge temperature and then runs the

appropriate compressor startup program. Once the startup program is complete, the compressor runs at the target rotation

speed.

The compressor speed is controlled according to two parts in normal operation:

In cooling mode: In a single system, the compressor speed is controlled according to the water outlet temperature and water

outlet setting temperature. In a combination system, the compressor of master unit is controlled according total water outlet

temperature and water outlet setting temperature, the compressor of the slave unit is controlled according to water inlet and

water outlet temperature. Both in a single system and combination system, the compressor speed is limited by the inverter

module temperature (calculated value), ambient temperature, discharge temperature, discharge pressure and air side heat

exchanger refrigerant total outlet temperature.

Summary of Contents for SCV-1400EB

Page 2: ......

Page 4: ...2...

Page 8: ...6...

Page 26: ...24...

Page 46: ...44 1 Electric Control Box Layout For SCV 750EB For SCV 1400EB...

Page 61: ...59 3 Wiring diagram 3 1 Single unit For SCV 750EB and SCV 1400EB...

Page 62: ...60 For SCV 900EB...

Page 63: ...61 For SCV 1800EB...

Page 78: ...76 5 5 E3 E4 E5 E7 Eb Ed EE EF EP EU Fb Fd Troubleshooting Digital display output...

Page 159: ......

Page 160: ...0 1 234 56 0 7 8 234 0 9 1 7 1 0 6 16 3 5 9 4 260 88 4 260 88 08 88 688 0 4 08 4 6 4A8 60 B...