2-29

2

Ba

sic O

pe

ra

tio

n

6

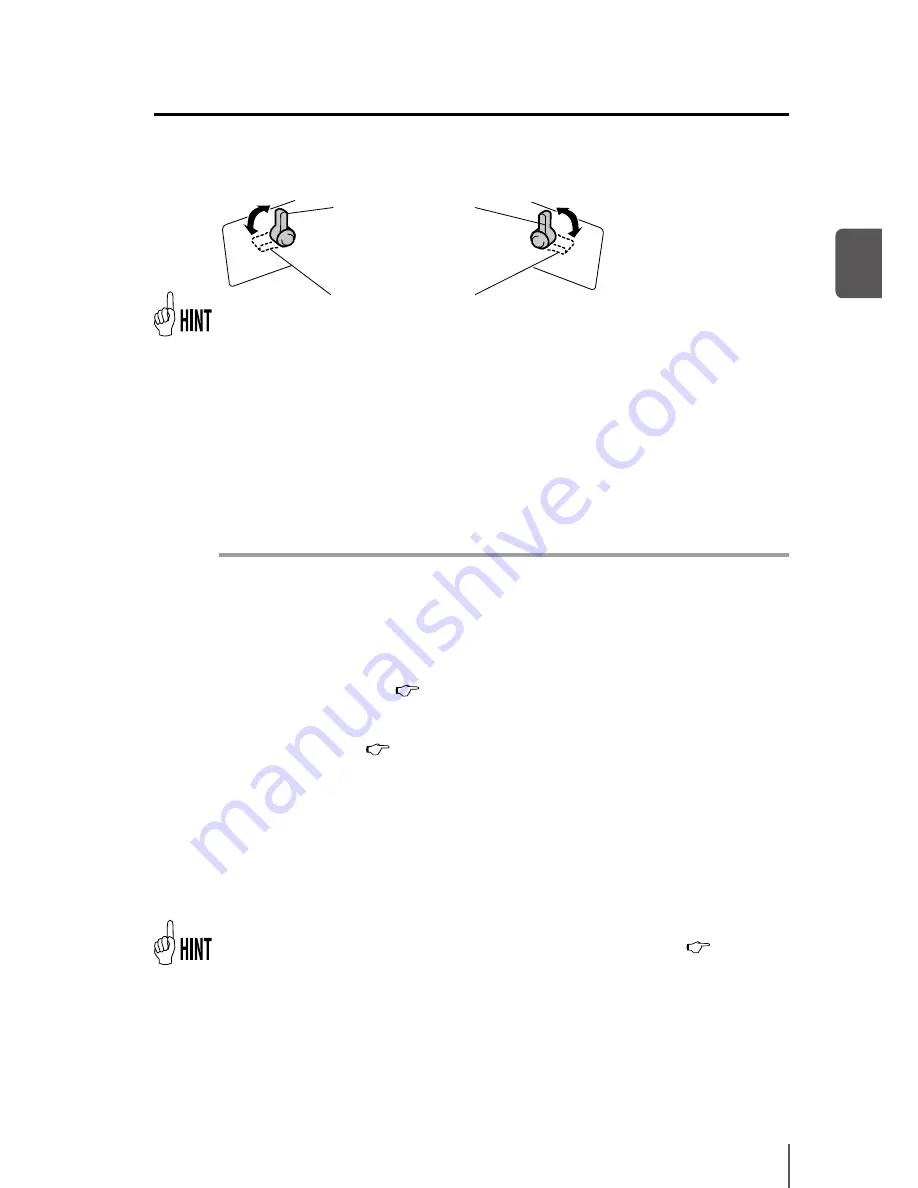

Switch the height of print head with the head up down mechanism.

¯

[High] is 0.5 mm higher than [Normal].

Generally, [Normal] is used for glossy and matte vinyl chloride, and [High] is used

for tarpaulin and FF. If the media thickness exceeds 0.5 mm, [High] should be used

regardless of the media type. Use also [High] even with thin media if it is severely

wrinkled or contains irregularities that may touch the print head.

7

Tighten the two (2) fixing screws.

Note

- Do not move the head up down mechanism with the head securing screws

tightened. The head up down mechanism may be broken.

- When changing the height of the print head, tighten the head securing screws

while pushing lightly the carriage downward.

- When changing the height of the print head, change [PH HEIGHT VAL] in the

MEDIA REG MENU also. (

P.3-31 [(18) PH HEIGHT VAL]

- A print shift may occur during bi-directional printing after changing the height of

the print head. In this case, adjust the bidirectional position in [BIDIR ADJ] of the

MEDIA REG MENU. (

P.3-32 [(27) BIDIR ADJ1 L] to [(32)BIDIR ADJ3 R]

- As the gap between the side plate of the printer and the carriage is narrow, if it is

hard to reach the head up down mechanism and head securing screws, move the

carriage to the right (or the left) with your hands.

- Confirm that the right and left head securing screws are tightened. If carriage

moves with the head securing screws loosened, they may strike the media or edge

guard, causing poor image quality and damage to the printer.

- Always operate the two head up down mechanisms at the same time and be sure

that they are set to the same position.

- During adjustment of the head height, the warning beep will be heard. (

P.3-56 [(5)

BEEP]

)

High (for thick media)

Normal (for thin (normal

thickness) media)

Summary of Contents for IP-5520

Page 4: ......

Page 6: ......

Page 48: ...1 24 ...

Page 92: ...2 44 ...

Page 224: ...5 26 ...

Page 248: ......