H

ow t

o u

se o

pti

on

s

5-17

5

Problems

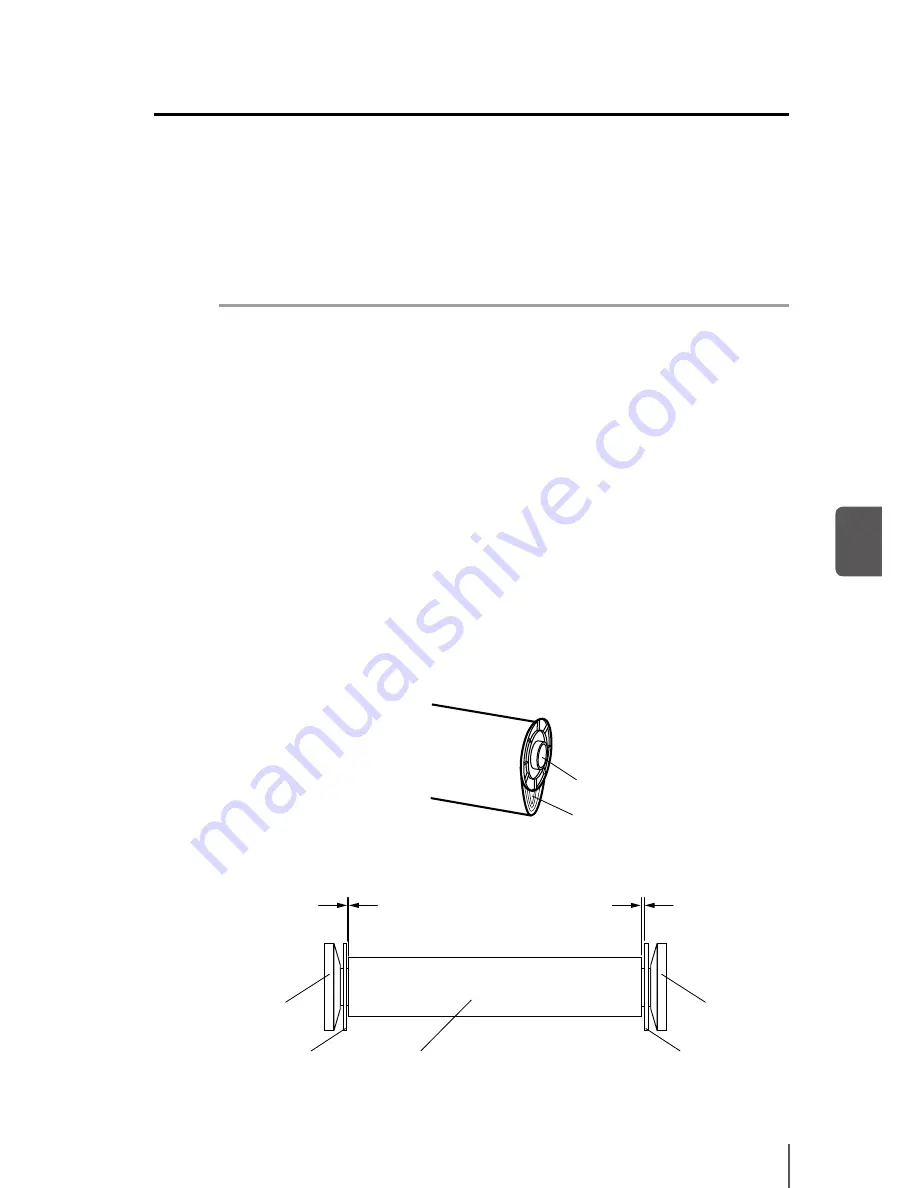

When printing with loose take-up configuration, under the following conditions

the media may become loose and a winding deviation may occur (see figure1).

Pay particular attention as if the media deviates, the winding torque may increase

resulting in take-up problems.

Note

- If a wound media if left for several hours, the media may become loose and

cause take-up problems.

- When performing consecutive prints with loose take-up configuration, assist

the take-up operation manually only for the first print.

- When printing with loose take-up configuration on rather elastic media,

the media may become loose and cause take-up problems. When using this

kind of media, try to not interrupt the take-up operation for a long time.

If the take-up operation happens to stop, assist the operation manually as

indicated above.

- Winding deviation in the media facilitates the formation of a slack and may

cause take-up problems.

- Install the media perpendicularly to the paper tube.

- Install a paper tube matching the width of the media.

- Check that the space between the media and the loose take-up flange is not

too large.

a and b must be so that the media and the loose take-up flange almost

contact during printing (see figure 2).

a

b

Movable side

flange

Movable side

flange

Loose take-up

flange

Media

Loose take-up

flange

Flange

Media

Figure 1 Media winding deviation

Figure 2

Summary of Contents for IP-5520

Page 4: ......

Page 6: ......

Page 48: ...1 24 ...

Page 92: ...2 44 ...

Page 224: ...5 26 ...

Page 248: ......