E-022-4-E

22

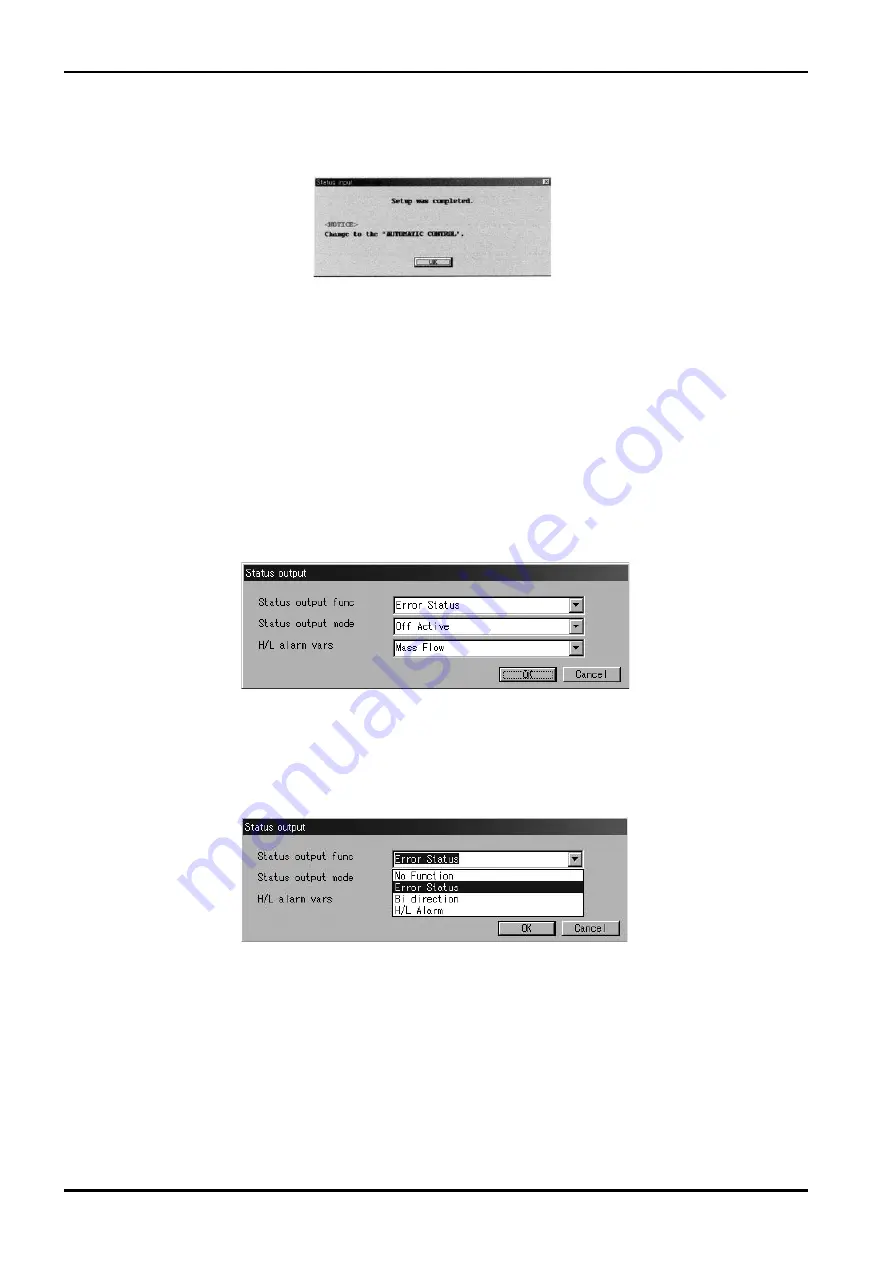

Fig.37

Fig.38

Fig.39

⑥

When the previous settings are replaced with the new settings just entered in response to clicking on

"OK"

,

a massage box as shown in Fig. 37 appears. Clicking on "OK" button at this point completes the

setup.

⑦

After clicking on "OK" button, the message box for filling in fields of items appears again. Click on

"Cancel" button to hide the setup message box.

To abort the setup process, click on "Cancel" button in the course of steps

②

through

④

.

3.6.7 Status Output

①

Click on "Setup (S)" at top-level menu of the screen, select "Status output" from "Config output" drop-

down list, and click on again.

②

A message box as shown in Fig. 38 appears. Status output function is set up at this window.

③

As shown in Fig. 39, select from the drop-down list the function to be set up for the status output by

clicking on the arrow mark at right of "Status output func"

.

Summary of Contents for EL 2310-05E Series

Page 71: ...E 022 4 E 71...