20. FAX ERROR

Field Service Ver. 1.1 May 2011

324

TROUBLESHOOTING

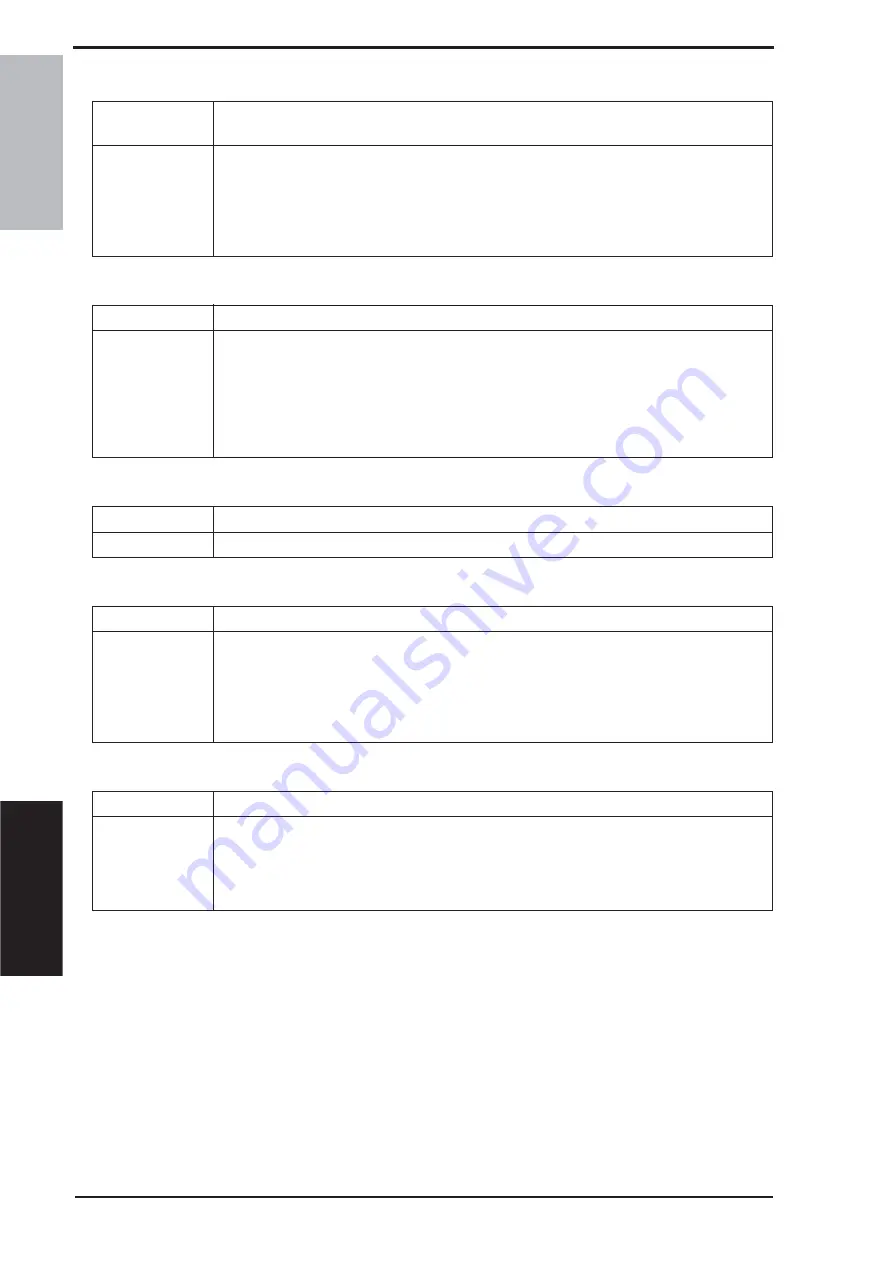

(55) Error code: 0065

(56) Error code: 0066

(57) Error code: 0070

(58) Error code: 0071

(59) Error code: 0072

Definition

Can not detect any control channel signal within 60 seconds after detect silence in

phase D.

Solution

1.

Ask sender resend the FAX again.

2.

Check the line condition whether is too noisy, if necessary, please replace a new

telephone line or contact your telecom service provider.

3.

Boost the TX level of sender's machine.

4.

Print out the protocol report, and provide it to technical center, ask for analyzing

the information.

Definition

Can not receive T.30 signal or carrier after sending CFR in V.34.

Solution

1.

Ask sender resend the FAX again.

2.

Check the line condition whether is too noisy, if necessary, please replace a new

telephone line or contact your telecom service provider.

3.

Change the machine RX speed to V.17, and then ask sender resend again.

4.

Boost the TX level of sender's machine.

5.

Print out the protocol report, and provide it to technical center, ask for analyzing

the information.

Definition

User press stop key within receiving.

Solution

1.

Ask sender resend the FAX again.

Definition

Memory full within receiving.

Solution

1.

Split the document into several copies at sender, and send them by several dif-

ferent times.

2.

Print out the receiving data which was stored in the FAX memory or delete the

unnecessary data.

3.

Reboot the machine.

4.

Execute MEMORY CLEAR.

Definition

Received EOR_Q signal.

Solution

1.

Check the line condition whether is too noisy, if necessary, please replace a new

telephone line or contact your telecom service provider.

2.

Reduce the TX level of sender's machine.

3.

Print out the protocol report, and provide it to technical center, ask for analyzing

the information.

d-Color MF2400

Summary of Contents for PF-P09

Page 1: ...SERVICE MANUAL Color Printer d Color MF2400 PF P09 Code Y113750 1...

Page 4: ...ii Blank Page...

Page 27: ...SERVICE MANUAL Color Printer d Color MF2400 Code Y113750 1...

Page 436: ...SERVICE MANUAL Color Printer Code Y113750 1 SERVICE MANUAL PF P09...

Page 457: ...UPDATINGSTATUS DATE UPDATEDPAGES PAGES CODE 12 2011 1ST EDITION 457 Y113750 1...