Clean the media input section of the stacker

Before you begin

Make sure you have the following cleaning materials at hand.

• Use GLOVES - UV INK (MEDIUM / LARGE)

• Use Lint Free Cloths (moistened with demi water)

• Demi water

When to do

Clearly visible pollution on the media input section of the stacker can cause pollution on the

printed output.

To clean the media input section of the stacker, do the following.

Procedure

1.

Pause the active print job.

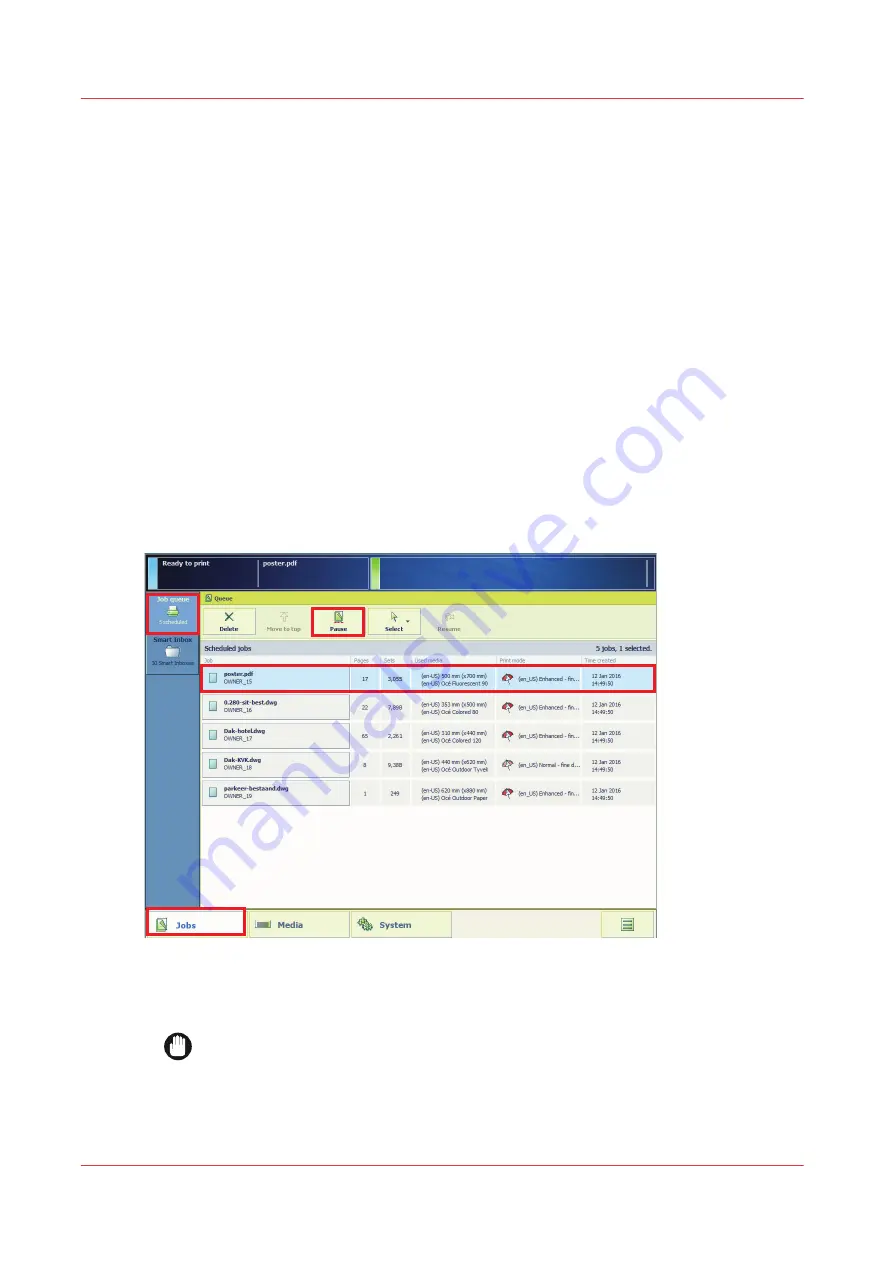

1. On the user panel tap on [Jobs]

2. Tap on [Job queue]

3. Select the active print job and tap on [Pause].

1

3

2

2.

Move the stacker away from the printer.

3.

Put on gloves and use a lint free cloth, slightly moistened with demi water, to carefully clean the

polluted surface.

IMPORTANT

Do not damage the sensors.

Clean the media input section of the stacker

216

Chapter 9 - Maintain the print system

Summary of Contents for ColorWave 900

Page 1: ...Operation guide Oc ColorWave 900 User Manual...

Page 7: ...Chapter 1 Introduction...

Page 14: ...Available documentation 14 Chapter 1 Introduction...

Page 15: ...Chapter 2 Explore the print system...

Page 33: ...Ease of operation Chapter 2 Explore the print system 33...

Page 40: ...Status of the printer 40 Chapter 2 Explore the print system...

Page 41: ...Chapter 3 Getting started...

Page 56: ...Move the printer 56 Chapter 3 Getting started...

Page 57: ...Chapter 4 Media handling...

Page 78: ...Check the media compatibility with folding devices 78 Chapter 4 Media handling...

Page 79: ...Chapter 5 Configure the print system...

Page 101: ...The Preferences System settings Chapter 5 Configure the print system 101...

Page 136: ...Accounting workflow 136 Chapter 5 Configure the print system...

Page 137: ...Chapter 6 Plan jobs...

Page 149: ...Chapter 7 Print jobs...

Page 163: ...Chapter 8 Adjust the print quality and print productivity...

Page 175: ...Chapter 9 Maintain the print system...

Page 190: ...Align printheads Manual horizontal 190 Chapter 9 Maintain the print system...

Page 259: ...Chapter 10 Troubleshooting...

Page 287: ...Chapter 11 Support...

Page 294: ...Downloads and support for your product 294 Chapter 11 Support...

Page 295: ...Chapter 12 References...

Page 319: ......