5 Mounting

Maschinenfabrik Reinhausen GmbH 2020

96

7545652/00 EN

VACUTAP

®

VR-Ex

If drying in the transformer tank, the following methods are possible:

▪ Vacuum-drying

▪ Vapor-phase drying

As an alternative to drying the on-load tap-changer in the transformer tank, it

can also be dried in an autoclave.

5.3.6.1 Vacuum-drying in the transformer tank

The on-load tap-changer head cover remains closed during the entire drying

process.

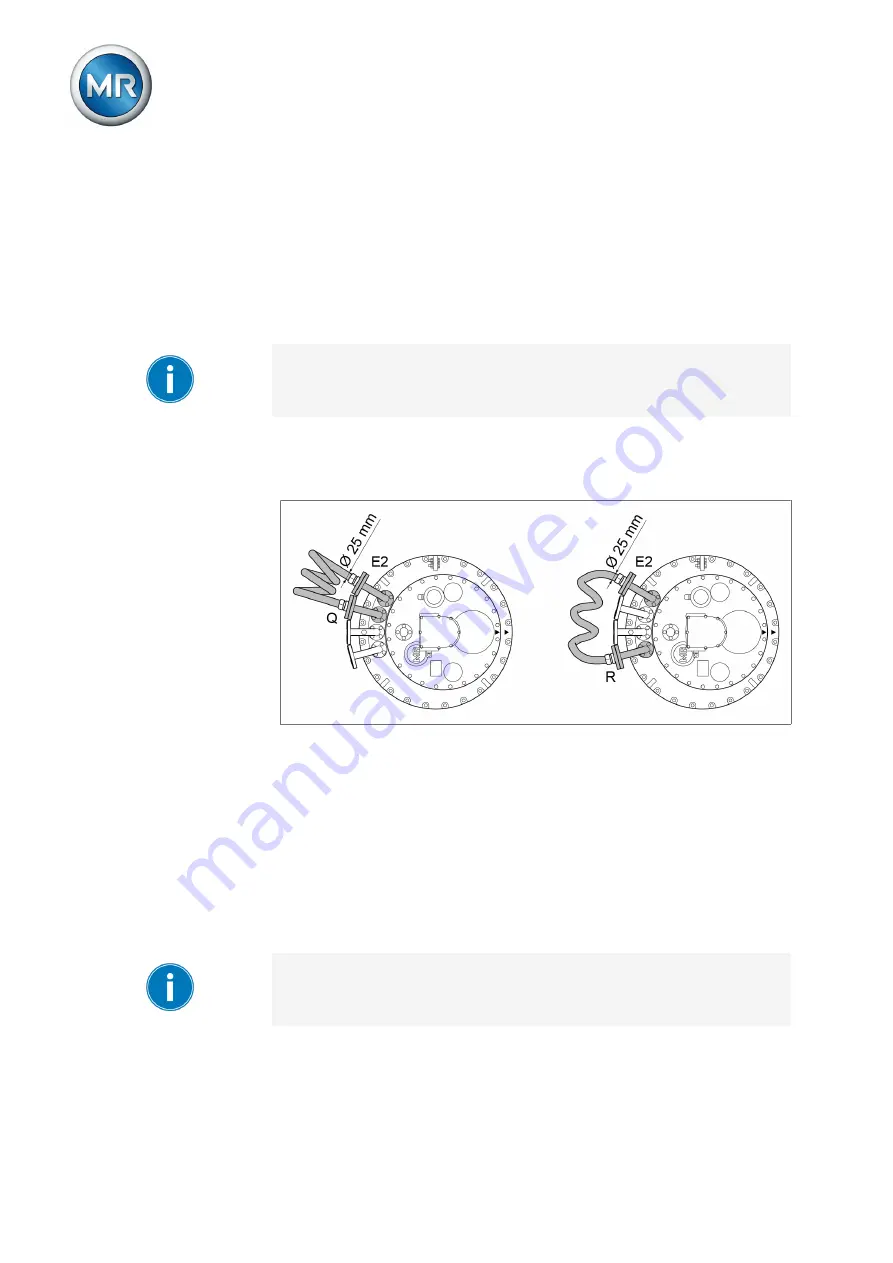

1. Establish a connecting lead between either connections E2 and Q or con-

nections E2 and R on the on-load tap-changer head.

2. Seal off unused pipe connections with a suitable blank cover.

Figure 95: Connecting lead

Vacuum-drying in the transformer tank

1. Heat up the on-load tap-changer in air at atmospheric pressure with a

temperature increase of approximately 10 °C/h to a final temperature of

maximum 110 °C.

2. Pre-dry the on-load tap-changer in circulating air at a maximum tempera-

ture of 110 °C for a period of at least 20 hours.

3. Vacuum-dry on-load tap-changer at between 105 °C and maximum

125 °C for at least 50 hours.

4. Residual pressure of no more than 10

-3

bar.

If you wish to perform another transformer ratio test after drying, proceed as

described in the section "Performing transformer ratio test following dry-

ing" [