5 Mounting

Maschinenfabrik Reinhausen GmbH 2020

93

7545652/00 EN

VACUTAP

®

VR-Ex

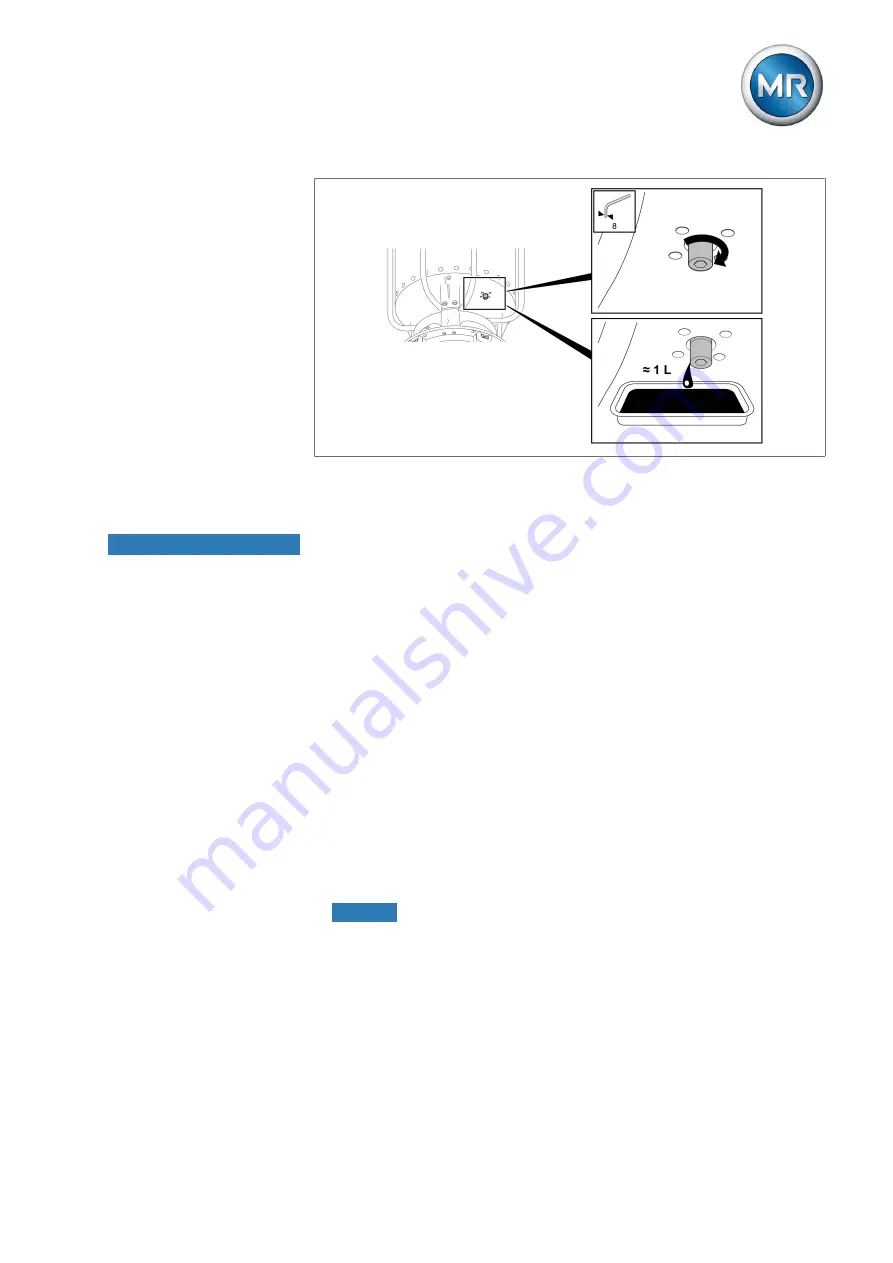

Figure 91: Kerosene drain plug

5.3.5.2.4 Drying the on-load tap-changer

NOTICE

Damage to the on-load tap-changer head cover and on-load tap-

changer accessories.

Both the on-load tap-changer head cover and the on-load tap-changer ac-

cessories will become damaged if they are dried.

► Never dry the on-load tap-changer head cover or the following acces-

sories: motor-drive unit, drive shaft, protective relay, pressure monitoring

device, pressure relief device, bevel gear, temperature sensor, oil filter

unit.

1. Supply kerosene vapor at a temperature of around 90°C. Keep this tem-

perature constant for 3 to 4 hours.

2. Increase the kerosene vapor temperature by approx. 10°C/hour to the de-

sired final temperature of max. 125°C at the on-load tap-changer.

3. Vacuum-dry on-load tap-changer at between 105°C and maximum 125°C

for at least 50 hours.

4. Residual pressure of no more than 10

-3

bar.

5.3.5.2.5 Closing kerosene drain plug

►

NOTICE!

An open kerosene drain plug leads to insulating fluid escaping

from the oil compartment and therefore to damage to the on-load tap-

changer. Close kerosene drain plug (tightening torque 20 Nm).