Control circuit specifications

Wiring

3 - 18

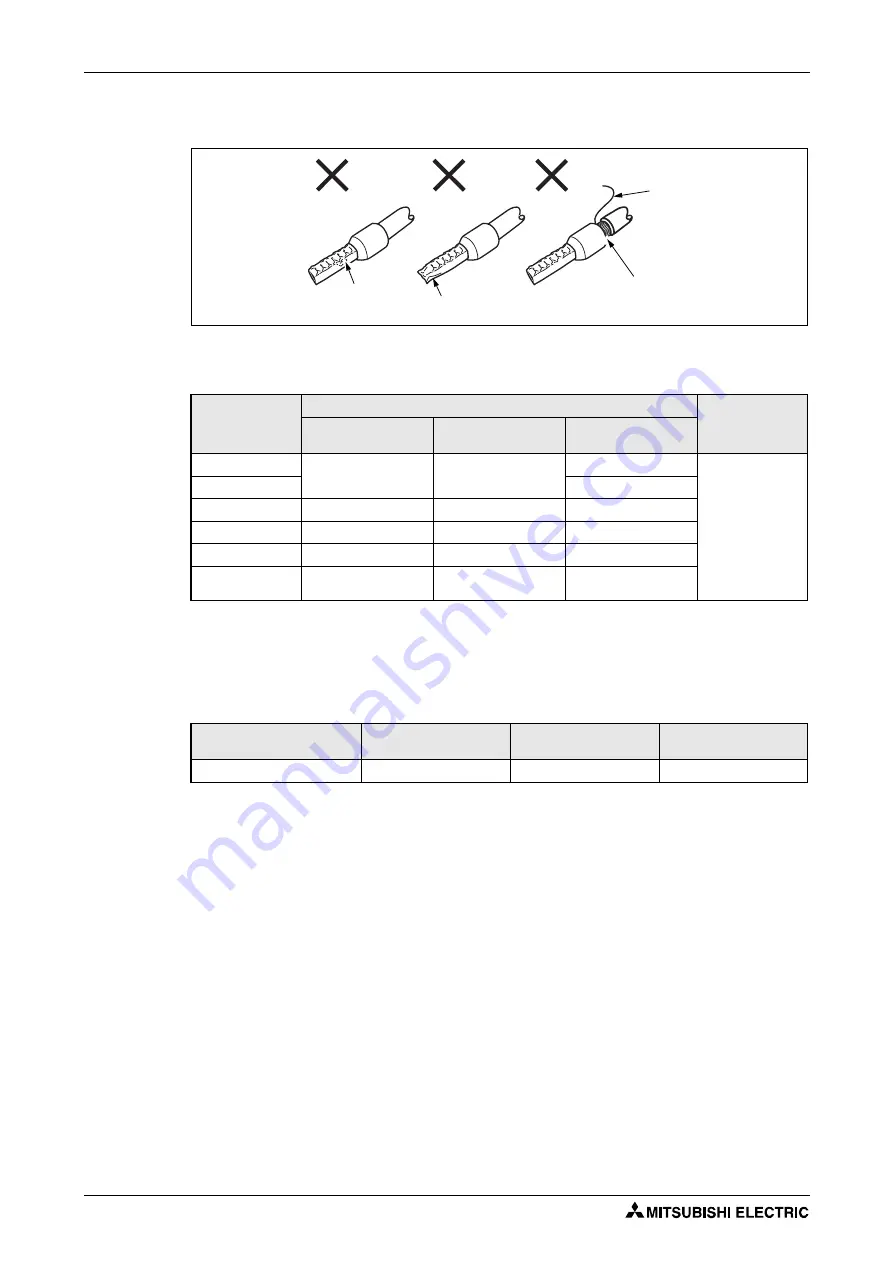

Check the condition of the wire end sleeve after crimping. Do not use a wire end sleeve of

which the crimping is inappropriate, or the face is damaged.

A bar terminal with an insulation sleeve compatible with MTW wire which has a thick wire

insulation.

Applicable for terminal ABC

I001985E

Fig. 3-9:

Incorrectly crimped wire end sleeves

Wire Size [mm²]

Wire End Sleeve Model

Recommended

Wire End Sleeve

Crimping Tool

With Insulation

Sleeve

Without Insulation

Sleeve

For UL Wire

0.3

Al 0,5-10WH

—

—

CRIMPFOX 6/6T-F

(Maker: Phoenix

Contact Co., Ltd)

0.5

AI 0,5-10WH-GB

0.75

Al 0,75-10GY

A 0,75-10

AI 0,75-10GY-GB

1

Al 1-10RD

A 1-10

AI 1-10RD/1000GB

1.25/1.5

Al 1,5-10BK

A 1,5-10

AI 1,5-10BK/1000GB

0.75

(for two wires)

Al-TWIN 2 × 0,75-

10GY

—

—

Tab. 3-13:

Recommended wire end sleeves (Maker: Phoenix Contact Co., Ltd)

Wire Size [mm²]

Wire End Sleeve

Product Number

Insulation

Product Number

Recommended Wire End

Sleeve Crimping Tool

0.3 to 0.75

BT 0.75-11

VC 0.75

NH 67

Tab. 3-14:

Recommended wire end sleeves (Maker: NICHIFU Co., Ltd)

Damaged

Crumpled tip

Wires are not inserted

into the shell

Unstranded wires

Summary of Contents for FR-D720S SC EC

Page 2: ......

Page 4: ......

Page 24: ...Description of the case Product checking and part identification 1 4 ...

Page 108: ...Operation panel Operation 4 20 ...

Page 436: ...Setting for the parameter unit and operation panel Parameter 6 286 ...

Page 484: ...Measurements on the main circuit Maintenance and inspection 8 14 ...

Page 504: ...Specification change Appendix A 20 ...

Page 505: ......

Page 506: ......

Page 510: ...Index Appendix A 24 ...

Page 511: ......