35

|

www.lakeshore.com

2.5 Considerations

for Microwave

Measurements

Lake Shore offers microwave configurations with ground-signal-ground (GSG) probe

geometry optimized for substrates patterned with coplanar waveguide structures.

Both signal and ground traces of the microwave structures must be patterned on the

top layer of the substrate to facilitate top side probing. Measurements can be

performed on both passive and active devices to characterize performance metrics

such as S-parameters, noise figure, or load-pull parameters.

Proper use of GSG microwave probes is more complex than of DC/RF probes. Proper

probe alignment of the GSG points with respect to the test substrate is required, as is

the proper probe planarization with respect to the plane of measurement. Also,

calibration may be desired to separate the frequency dependent losses of the

measurement setup from the actual device under test.

The remaining sections in this chapter describe details of the microwave probe

measurement setup, as well as concepts and techniques that are important for

making good microwave measurements in the probe station.

2.5.1 Microwave Cables

and Connectors

Microwave cables form transmission lines that carry high frequency signals from the

signal connection point outside the vacuum chamber to probe points near the cooled

sample. The type and quality of microwave cables and their associated connectors

determine the frequency range and overall performance of microwave

measurements in the probe station. Properly installed, the cables provide a low loss,

broad band electrical path with minimal crosstalk. Also, they need to be compatible

with the cryogenic temperatures and vacuum for the Model CRX-6.5K.

The geometry of the Model CRX-6.5K requires that the cables extend 229 mm (9 in)

into the vacuum chamber with a single 90 degree bend. The total length of the

microwave cable is approximately 279 mm (11 in). Probe station layout inherently

contributes some signal loss. Lake Shore recommends the following for best

performance:

1. Calibrate the measurement setup as described in section 2.5.4.

2. Re-tighten the connectors to manufacturer’s specified torque after repeated

thermal cycling.

3. Keep external cables as short and direct as possible.

Microwave probes must be specified with the same frequency and connector type as

the probe cable. TABLE 2-3 summarizes the two microwave probe frequency ranges

and associated connectors.

For reference, FIGURE 2-29 to FIGURE 2-30 show plug and socket, head-on views of

the three standard types of microwave connectors. Note that both types look very

similar. Side by side, differences in the connectors can be seen primarily in the head-

on view in the thickness of outer conductor and spacing between the inner and outer

conductor.

The connector types are physically similar and can sometimes, but not always, be

interchanged; care should be taken not to damage probes or cables by attempting to

mate them improperly.

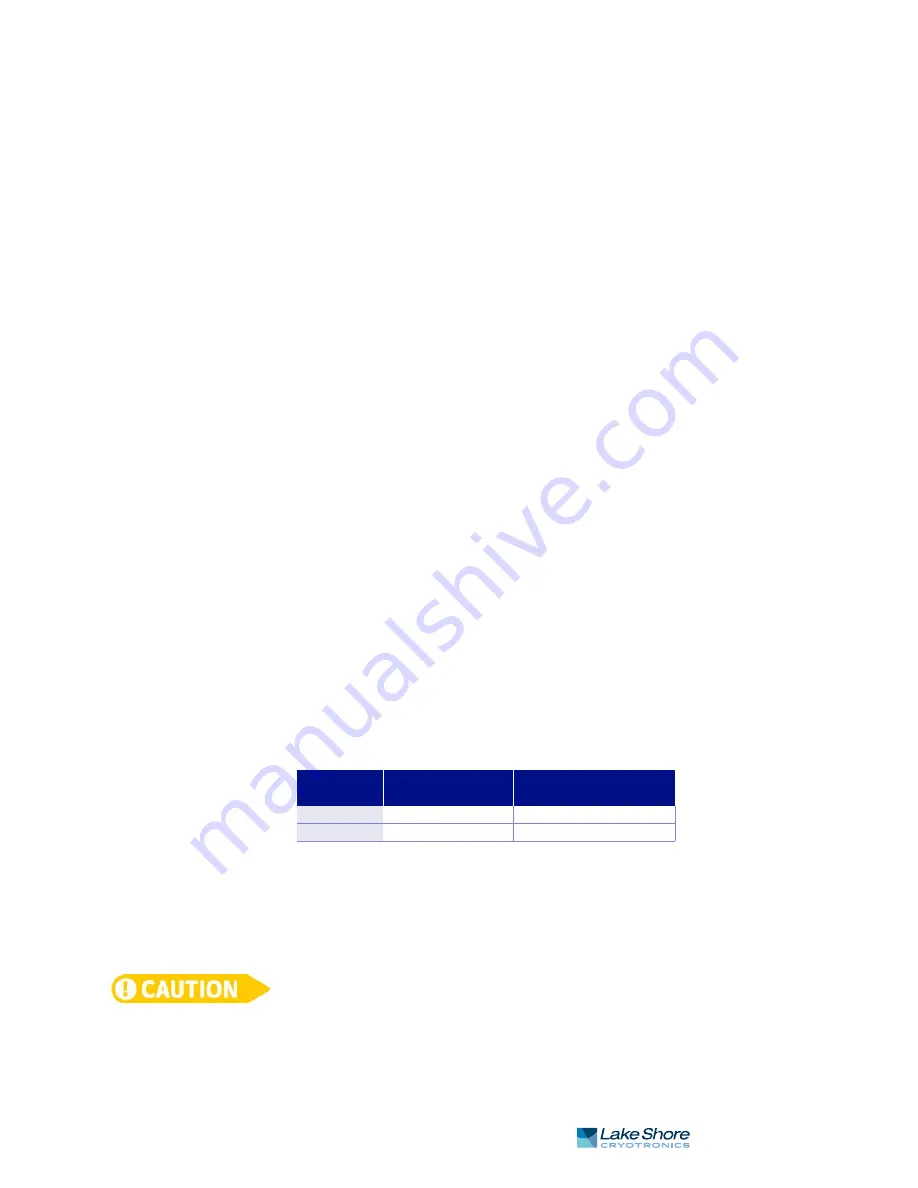

Highest rated

frequency

Connector

Mates with

40 GHz

K-type (2.92 mm)

Standard SMA connectors

67 GHz

V-type (1.85 mm)

2.4 mm connectors

TABLE 2-3

Microwave probe frequency ranges and associated connectors