141

|

www.lakeshore.com

6.3.3.5 Takes Too Long to Cool

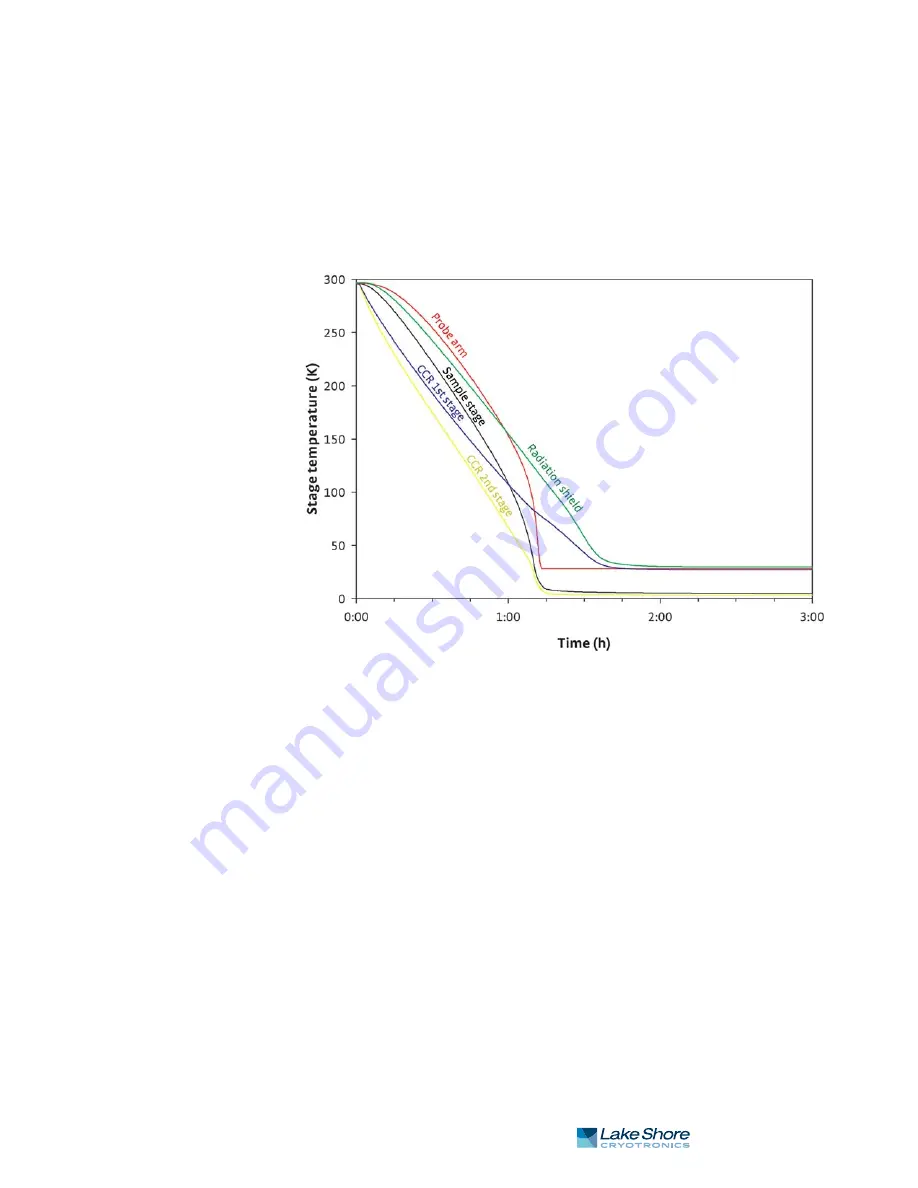

FIGURE 6-5 illustrates a typical Model CRX-6.5K sample cooling assembly cooling

curve. The system cools slowly at first because the heat capacity of the materials is

high near room temperature. As the materials cool, their heat capacity drops and the

system cools more quickly. This impacts warm up time and temperature control time

constants.

If the cooling cycle takes significantly longer than the times represented in the

cooling curve (FIGURE 6-5), investigate the possible causes listed in section 6.3.3.2 to

section 6.3.3.4.

6.3.3.6 Erratic Temperature Readings

The Model CRX-6.5K sample stage is a stable temperature control platform and

reasonable temperature control can be achieved over the entire temperature range.

Short term temperature control of a few tens of millikelvins should be expected

around base temperature. As the system approaches maximum temperature, short

term control stability degrades somewhat, but should remain below 1 K in a properly

tuned system.

Considerations when regulating with electronic temperature controls

When operating with the electronic temperature controllers the following problems

may cause unstable or erratic temperature readings.

D

Controller PID parameters are not tuned properly—the controller tuning

parameters listed in section 4.5.5 are a good starting point, but may need to be

modified to achieve optimum control stability based on specific measurement

conditions. Heater range is important to tuning and also must be set properly.

D

Controlling too close to base temperature—attempt to control a few kelvin

higher in temperature, then gradually lower the setpoint to identify the lowest

practical electronic control temperature.

D

Electrical noise—ground loops and other electrical noise can impact the

controller’s temperature readings

FIGURE 6-5

Typical Model CRX-6.5K sample cooling assembly cooling curve with 4 arms