Recovery, loading and transport

W9272-8135-1

41

05/2020

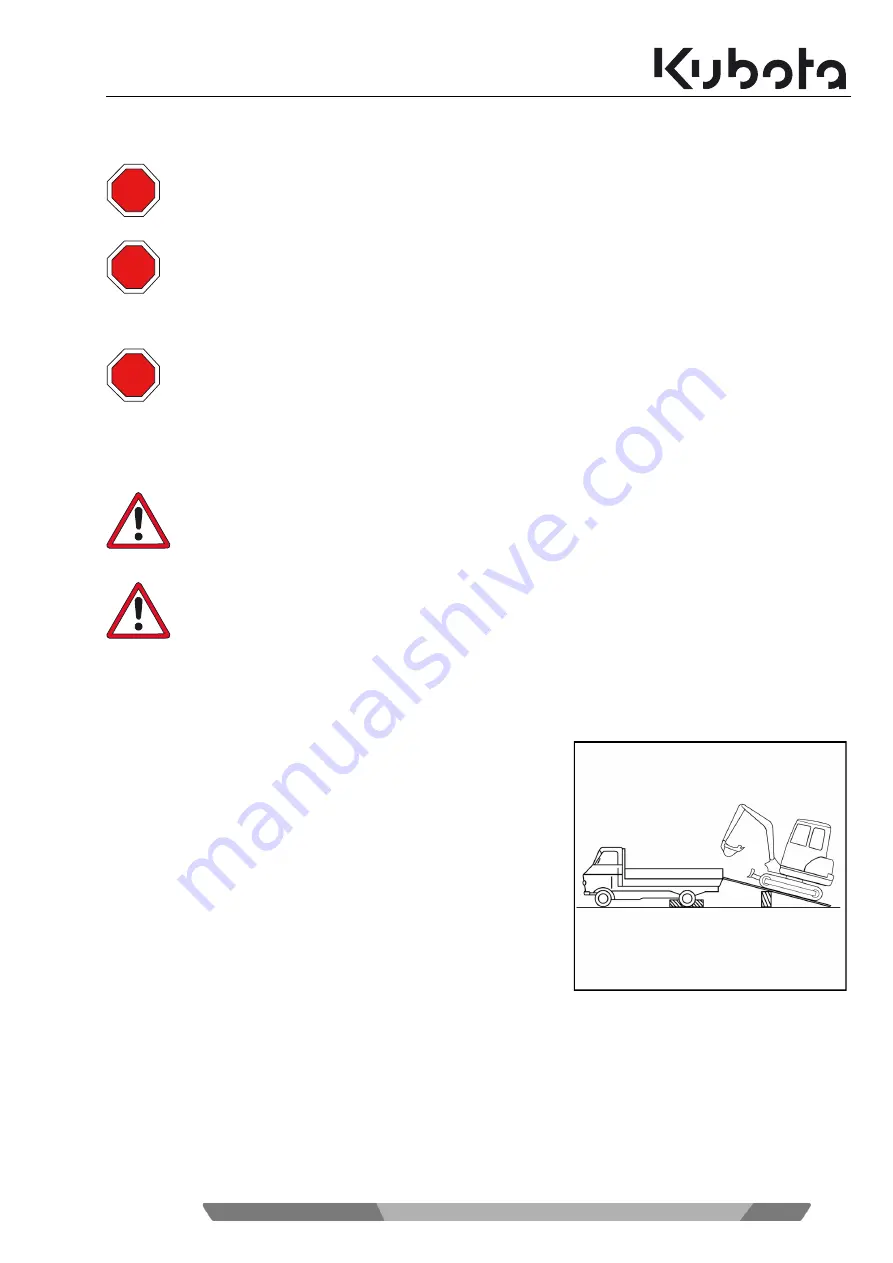

Transport on a flat bed trailer

Provide approved and labelled lashing material, such as lashing straps or sling chains, that are appropriate

for the machine’s weight (page 46).

Place the loading ramps on the transport vehicle at an angle of

10° to 15°. When doing so, take into account the track width of

the machine.

Fasten the ramps to the transport vehicle in such a way that

they do not slide when driving the machine onto it.

Align the machine with the centre of the ramps and drive it

straight onto the loading area until it has reached the parking

space.

Lower the dozer onto the loading area.

Rotate the swivel frame 180° until the front attachments face

the rear of the transport vehicle.

Completely retract the arm and bucket. Lower the boom until

the bucket linkages touch the loading area.

Adhere to the „Safety rules“ chapter (page 13) and the „Safety rules for transport“ section (page 38).

Mortal danger by crushing!

Nobody is allowed in the loading area or in close proximity to that area while operating the machine

on the ramp and in the loading area, e.g. when driving onto the ramp or when rotating the swivel

frame.

- Guides must maintain a safe distance from the machine.

Risk of accidents due to machine falling down!

When changing the direction of travel or when manoeuvring the machine, it can slip and fall off the

ramp or loading area.

- Do not turn or steer when driving up the ramps.

- If the machine cannot be driven safely and in straight line onto the loading area, drive the ma-

chine back down, realign it and drive straight ahead onto the area.

- Only work with a guide.

Caution when rotating the swivel frame!

The front attachments can hit the transport vehicle. This can damage the transport vehicle and the

machine.

- Only work with a guide.

Risk of accidents due to malfunction in transport safety device!

The machine’s lashing points are designed and constructed to secure the machine safely. If fastening

points other than the lashing points described here are used, the transport safety device could mal-

function and the machine could slip or fall from the transport vehicle while being transported.

- Only used the indicated lashing points for the transport safety device.

STOP

STOP

STOP

Summary of Contents for U50-5

Page 1: ...GB COMPACT EXCAVATOR MODEL U50 5 OPERATING INSTRUCTIONS W9272 8135 1 Original 05 2020...

Page 38: ...36 W9272 8135 1 05 2020 Safety rules...

Page 54: ...52 W9272 8135 1 05 2020 Description of the machine...

Page 74: ...72 W9272 8135 1 05 2020 Assembly and functions...

Page 164: ...162 W9272 8135 1 05 2020 Operation...

Page 222: ...220 W9272 8135 1 05 2020 Maintenance...

Page 224: ...222 W9272 8135 1 05 2020 Safety inspection...

Page 234: ...232 W9272 8135 1 05 2020 Software information...

Page 235: ...Software information W9272 8135 1 233 05 2020...

Page 236: ......