Chapter 3 Operation

3.4 Field Network

Address Map

65

3.4 Field Network Address Map

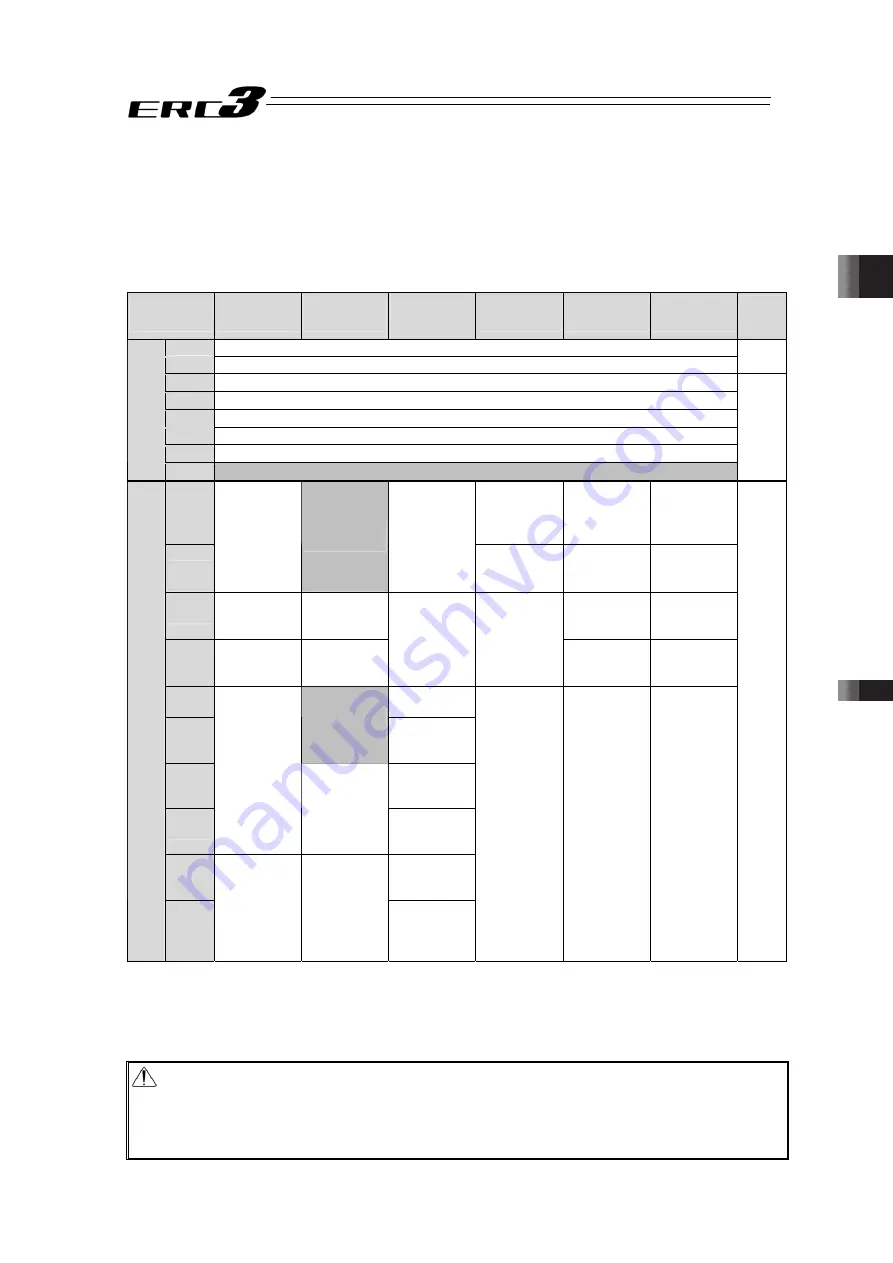

3.4.1 PLC Address Construction by each Operation Mode

The PLC address domain to be occupied differs depending on the operation mode.

Refer to the example in Section 3.4.2 for the assignment.

• PLC Output → ERC3 Input (n is PLC output top word address to ERC3)

(Note 1)

PLC Output

Area

Simple Direct

Mode

Positioner 1

Mode

Direct

Indication

(Full) Mode

Positioner 2

Mode

Positioner 3

Mode

Remote I/O

Mode

(Note 2)

Details

n

Gateway Control 0

n+1

Gateway Control 1

3.4.3

n+2

Command

n+3

Data 0

n+4

Data 1

n+5

Data 2

n+6

Data 3

ERC3 Gateway C

on

tro

l A

rea

n+7

Occupied Area

(Note 3)

3.4.9

n+8

Specified

Position No.

(Axis No.0)

Control

Signal/

Position No.

(Axis No.0)

Assignment

Area for Axis

No.0

n+9

Target

Position

(Axis No.0)

Occupied

Area

(Note 3)

Target

Position

(Axis No.0)

Control

Signal

(Axis No.0)

Assignment

Area for Axis

No.1

Assignment

Area for Axis

No.1

n+10

Specified

Position No.

(Axis No.0)

Specified

Position No.

(Axis No.0)

Assignment

Area for Axis

No.2

Assignment

Area for Axis

No.2

n+11

Control

Signal

(Axis No.0)

Control

Signal

(Axis No.0)

Positioning

Width

(Axis No.0)

Assignment

Area for Axis

No.1

Assignment

Area for Axis

No.3

Assignment

Area for Axis

No.3

n+12

Speed

(Axis No.0)

n+13

Occupied

Area

(Note 3)

Acceleration/

Deceleration

(Axis No.0)

n+14

Pressing

Current Limit

(Axis No.0)

n+15

Assignment

Area for Axis

No.1

Assignment

Area for Axis

No.1

Control

Signal

(Axis No.0)

n+16 to

n+23

Assignment

Area for Axis

No.1

Con

necte

d

Axes Control

Area

n+24 to

n+71

Assignment

Area for Axis

No.2 and

later

Assignment

Area for Axis

No.2 and

later

Assignment

Area for Axis

No.2 and

later

Assignment

Area for Axis

No.2 and

later

3.4.4

to

3.4.8

(Note 1) For CC-Link, n and n+1 are for input and output bit addresses, and n+8 is for the top

address of data register.

(Note 2) Remote I/O Mode occupies 12 words no matter how many axes are connected.

(Note 3) This is the

area

occupied unconditionally. Therefore, this

area

cannot be used for any

other purpose.

Caution : 1) Remote I/O Mode cannot be used together with other modes.

2) Only Remote I/O Mode can be selected in MEC Mode Type.

3) Only Positioner 3 Mode and Remote I/O Mode can be selected in

MECHATROLINK and CompoNet. (CompoNet occupies 32 bytes no matter of the

number of axes.)

ME0302-4A

Summary of Contents for ERC3

Page 1: ...IAI Corporation ERC3 Gateway Unit Instruction Manual Forth Edition ...

Page 2: ......

Page 4: ...ME0302 4A ...

Page 8: ...ME0302 4A ...

Page 35: ...Chapter 1 Specifications Check 1 6 Option 27 1 6 Option はケーブル長 ME0302 4A ...

Page 54: ...Chapter 2 Wiring 2 3 Wiring Method 46 ME0302 4A ...

Page 158: ...Chapter 3 Operation 3 8 Field Network LED Indication 150 ME0302 4A ...

Page 160: ...Chapter 4 I O Parameter 152 ME0302 4A ...

Page 176: ...Chapter 5 Troubleshooting 5 4 Alarm List 168 ME0302 4A ...

Page 186: ......

Page 187: ......