82

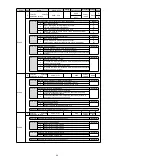

Fault contents

Reason

Confirmation method

The treatment measures

Excessive speed

overshoot at start

and stop

Improper matching of servo

gain

Confirm whether gain adjustment

has been implemented.

Perform automatic adjustment (no upper

command).

The speed loop gain (Pn100) is

set too high

Confirm the setting value of speed

loop

gain

(PN100).

Factory

setting: Kv = 40.0 Hz

Set the correct speed loop gain (Pn100)

setting.

The set value of the position

loop gain (Pn102) is too high

Confirm the set value of position

loop gain (Pn102). Factory setting:

Kp = 40.0/s

Set the correct setting value of position

loop gain (Pn102).

The speed loop integration

time parameter (Pn101) is not

set correctly

Confirm the set value of integral

time parameter (Pn101) of speed

loop. Factory setting: Ti = 20.0 ms

Set the correct speed loop integration time

parameter (Pn101) setting value.

The setting value of rotational

inertia ratio or mass ratio

(Pn103) is incorrect

Confirm the set value of the

moment of inertia ratio or mass

ratio (Pn103).

Set the correct moment of inertia or mass

ratio (Pn103).

Torque command saturation

Confirm

torque

command

waveform.

Use the mode switch function.

Thrust limit (Pn483, Pn484)

remains factory set

Thrust Limit: Factory Setting

Pn483 = 30%

,

Pn484 = 30%

Set the correct thrust limit (Pn483, Pn484)

value.

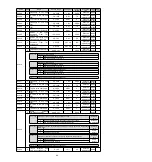

Error in absolute

value

encoder

position deviation

(deviation between

the position when

the power supply is

OFF

and

the

position when the

power supply is

ON again recorded

by

the

upper

device)

Mutual interference occurred

due to incorrect specifications

of cables used for encoders.

Confirm whether the cable for

encoder meets the specification.

The cable specification: double

stranded shielded wire or double

stranded unified shielded wire with

core wire of more than 0.12mm

2

and tinned soft copper stranded

wire.

Use cables that meet specifications.

Because the encoder cable is

too long, mutual interference

occurs

Confirm the cable length for

encoder.

Set the length of encoder cable within 50m.

Due to encoder cable damage,

mutual interference occurs

Confirm whether the encoder

cable is clamped and the cladding

is damaged.

Replace encoder cable and change cable

laying environment.

Excessive mutual interference

on encoder cable

Verify that the encoder cable is

tied together or too close to the

high current wire.

Change the laying environment of encoder

cables so as not to be affected by surge

voltage of high-current wires.

The potential of FG changes

due to the influence of servo

motor-side equipment (welding

machine, etc.)

Confirm the grounding status of

servo motor side equipment

(forget

grounding,

incomplete

grounding).

Properly ground the servo motor side

equipment to prevent shunt to encoder side

FG.

Error in calculation of servo

drive pulse due to mutual

interference

Confirm whether there is mutual

interference between encoder or

serial conversion unit and signal

line.

Anti-interference measures shall be taken

for the connection of encoder or serial

conversion unit.

Encoder

is

affected

by

excessive vibration impact.

Confirm

whether

mechanical

vibration occurs. Confirm the

installation state of servo motor

(precision of installation surface,

fixed state, eccentric core).

Reduce mechanical vibration. And the

installation state of the servo motor or the

encoder is improved.

Encoder failure

-

Replace the servo motor or encoder.

Servo drive failure

-

Replace the servo drive.

Error

in

reading

rotation

number data or absolute value

encoder position data of upper

device

Confirm the error detection part of

the upper device.

Make the error detection part of the upper

device work normally.

The upper device is used to

confirm whether the parity data

has been checked. Prepare the

data or absolute value of the

number of Coil

Parity check of rotation number of coil data

or absolute value encoder position data is

performed.

Confirm whether there is mutual

interference on the cable between

the servo drive and the upper

device.

Anti-interference measures shall be taken

to check the parity of rotation number of

coil data or absolute value encoder position

data again.

Overtravel

(OT)

occurred.

The

drive

input

(P-OT/N-OT)signal of forward /

reverse side is input

Confirm the voltage of the external

power supply (+24 V) for the input

signal.

Set the voltage of the external power

supply (+24V) for the input signal to the

correct value.

Confirm the operating state of the

over-travel limit switch.

Make the over-travel limit switch operate

normally.

Confirm

the

wiring

of

the

overtravel limit switch.

Correct wiring of over-travel limit switch.

Confirm

the

set

value

of

over-travel input signal distribution

(Pn50A or Pn50B).

Set parameters correctly.

The misoperation of the drive

input (P-OT/N-OT) signal on

the forward/reverse side is

prohibited

Confirm whether the voltage of the

external power supply (+24 V) for

the input signal fluctuates.

Eliminate voltage fluctuation of external

power supply (+24 V) for input signal.

Confirm whether the action state

of the overtravel limit switch is

unstable.

So that the action state of the overtravel

limit switch is stable.

Confirm

the

wiring

of

the

overtravel limit switch (cable

damage, screw fastening status,

etc.).

Correct wiring of over-travel limit switch.

Error in the signal of the drive

input

(P-OT/N-OT)

that

prohibits

forward/reverse

rotation for parameters (Pn50A

= n.X

, Pn50B =

n.

X)

Confirm P-OT signal allocation

Pn50A= n.X

.

If other signals are assigned to PN50A =

n.X

, the P-OT signal is reassigned to

this parameter.

Confirm N-OT signal distribution

Pn50B=n.

X.

If

other

signals

are

assigned

to

Pn50B=n.

X, then the N-OT signal is

reassigned to this parameter.

Servo motor stop method

selection error

Confirm the stop method when

servo is OFF (Pn001 = n.

X,

or pn 001 = n.

).

Select a servo motor stop method other

than free running stop.

Confirm the stop method for Select a servo motor stop method other