4.18 Parameters: 21-** Ext. Closed Loop

4.18.1 21-0* Ext. CL Autotuning

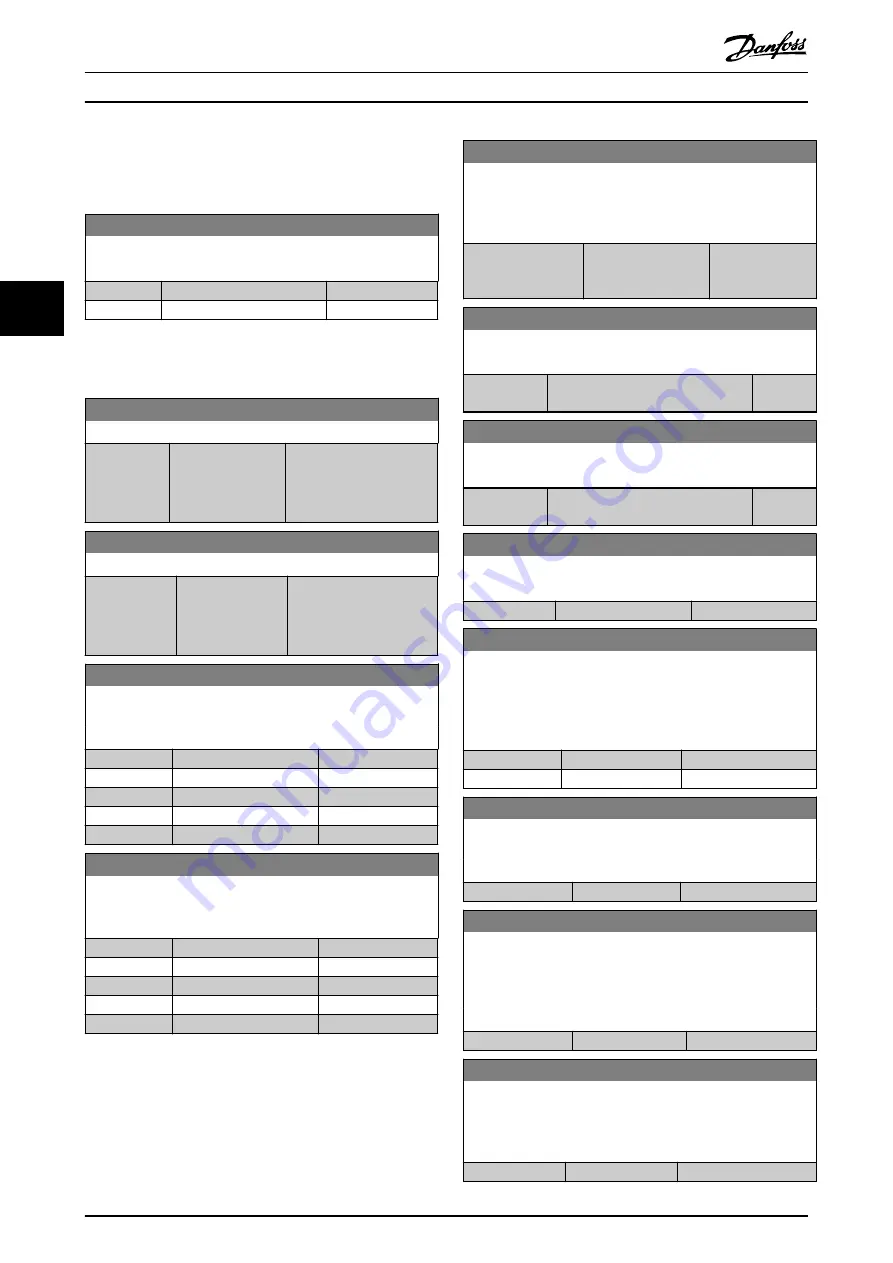

21-09 Extended PID Enable

Select the Extended CL PID controller that is to be autotuned.

Option:

Function:

[0]

*

Disabled

[1]

Enabled Ext CL1 PID

4.18.2 21-1* Ext. Closed-loop Reference/

feedback

21-11 Ext. 1 Minimum Reference

Range:

Function:

0 ExtPID1Unit

*

[ -999999.999 -

999999.999

ExtPID1Unit]

This parameter sets the

minimum value that can be

obtained by the sum

setpoint and reference.

21-12 Ext. 1 Maximum Reference

Range:

Function:

100

ExtPID1Unit

[ -999999.999 -

999999.999

ExtPID1Unit]

This parameter sets the

maximum value that can

be obtained by the sum of

the setpoint and reference.

21-13 Ext. 1 Reference Source

This parameter defines which input on the frequency converter

should be treated as the source of the reference signal.

Option:

Function:

[0]

*

No function

[1]

Analog Input 53

[2]

Analog Input 54

[7]

Frequency input 29

[8]

Frequency input 33

21-14 Ext. 1 Feedback Source

This parameter defines which input on the frequency converter

should be treated as the source of the feedback signal.

Option:

Function:

[0]

*

No function

[1]

Analog Input 53

[2]

Analog Input 54

[3]

Frequency input 29

[4]

Frequency input 33

21-15 Ext. 1 Setpoint

This parameter is used as the reference to compare the feedback

values with. The setpoint can be offset with digital, analogue or

bus references.

Range:

Function:

0 ExtPID1Unit

*

[-999999.999 -

999999.999

ExtPID1Unit]

21-17 Ext. 1 Reference [Unit]

Returns the resulting reference value.

Range:

Function:

0 ExtPID1Unit

*

[-999999.999 - 999999.999

ExtPID1Unit]

21-18 Ext. 1 Feedback [Unit]

Returns the feedback value.

Range:

Function:

0 ExtPID1Unit

*

[-999999.999 - 999999.999

ExtPID1Unit]

21-19 Ext. 1 Output [%]

Returns the Ext. Closed Loop 1 PID controller output value.

Range:

Function:

0 %

*

[0 - 100 %]

21-20 Ext. 1 Normal/Inverse Control

Select Normal if the controller output should be reduced when

the feedback is higher than the reference. Select Inverse if the

output should be increased when the feedback is higher than

the reference.

Option:

Function:

[0]

*

Normal

[1]

Inverse

21-21 Ext. 1 Proportional Gain

The proportional gain indicates the number of times the error

between the setpoint and the feedback signal is to be applied.

Range:

Function:

0.01

*

[0 - 10 ]

21-22 Ext. 1 Integral Time

The integrator provides an increasing gain at a constant error

between the setpoint and the feedback signal. The integral time

is the time needed by the integrator to reach the same gain as

the proportional gain.

Range:

Function:

10000 s

*

[0.01 - 10000 s]

21-23 Ext. 1 Differentation Time

The differentiator does not react to a constant error. It only

provides a gain when the error changes. The quicker the error

changes, the stronger the gain from the differentiator.

Range:

Function:

0 s

*

[0 - 10 s]

Parameter Descriptions

VLT

®

AutomationDrive FC 360

108

Danfoss A/S © 7/2015 All rights reserved.

MG06C602

4

4