•

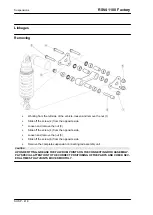

Position the two halves of the special

tool on the shaft behind anti-dust seal

(3), together with the respective buffer.

•

Grip the special tool and push the anti-

dust seal (3) into its housing on the

sleeve (2).

•

Grasp the shaft and move it slowly, in

alternating directions a few times.

CAUTION

THE SHAFT MUST SLIDE FREELY WITHIN THE SLEEVE,

WITHOUT OBSTRUCTIONS.

Filling oil

•

Clamp the forks in a vice using the special tool.

•

Fill the forks with oil until the air bubbles

trapped inside are forced out.

Oil level: 220 mm (8.66 in) (from the edge of the

sleeve, without spring or pre-loading tube).

THE SLEEVE MUST BE PERFECTLY UPRIGHT IN ORDER

TO MEASURE THE CORRECT OIL LEVEL. THE OIL LEVEL

MUST BE THE SAME IN BOTH STANCHIONS.

Characteristic

Oil for forks

382 cc (0,084 Uk gal) (for each shaft)

RSV4 1100 Factory

Suspensions

SUSP - 403

Summary of Contents for RSV4 1100 Factory

Page 1: ...SERVICE STATION MANUAL 2Q000401 RSV4 1100 Factory ...

Page 4: ......

Page 6: ...INDEX OF TOPICS CHARACTERISTICS CHAR ...

Page 55: ...INDEX OF TOPICS SPECIAL TOOLS S TOOLS ...

Page 63: ...INDEX OF TOPICS MAINTENANCE MAIN ...

Page 89: ...INDEX OF TOPICS ELECTRICAL SYSTEM ELE SYS ...

Page 245: ...INDEX OF TOPICS ENGINE FROM VEHICLE ENG VE ...

Page 270: ...INDEX OF TOPICS ENGINE ENG ...

Page 384: ...INDEX OF TOPICS POWER SUPPLY P SUPP ...

Page 387: ... Remove the fuel pump Injection RSV4 1100 Factory Power supply P SUPP 387 ...

Page 393: ...INDEX OF TOPICS SUSPENSIONS SUSP ...

Page 417: ...INDEX OF TOPICS CHASSIS CHAS ...

Page 455: ...INDEX OF TOPICS BRAKING SYSTEM BRAK SYS ...

Page 457: ...Operating diagram ABS functional diagram key RSV4 1100 Factory Braking system BRAK SYS 457 ...

Page 488: ...INDEX OF TOPICS COOLING SYSTEM COOL SYS ...

Page 499: ...INDEX OF TOPICS BODYWORK BODYW ...

Page 540: ...INDEX OF TOPICS PRE DELIVERY PRE DE ...

Page 546: ... Fit the two seater saddle Pre delivery RSV4 1100 Factory PRE DE 546 ...