Safety instructions 15

•

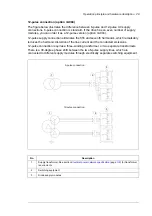

To prevent the drive module from falling, attach its top lifting lugs with chains to the

cabinet frame before you push the module into the cabinet and pull it from the

cabinet. Work carefully preferably with help from another person as shown below.

Keep a constant pressure with one foot on the base of the module to prevent the

module from falling on its back

•

Beware of hot surfaces. Some parts, such as heatsinks of power semiconductors,

remain hot for a while after disconnection of the electrical supply.

•

Make sure that debris from borings and grindings does not enter the drive during the

installation. Electrically conductive debris inside the drive may cause damage or

malfunction.

•

Make sure that there is sufficient cooling.

•

Before you connect voltage to the drive, make sure that the cabinet doors are closed.

Keep the doors closed during the operation. Obey the panel builder’s instructions.

•

Before you adjust the drive operation limits, make sure that the motor and all driven

equipment can operate throughout the set operation limits.

•

Before you activate the automatic fault reset or automatic restart functions of the drive

control program, make sure that no dangerous situations can occur. These functions

reset the drive automatically and continue operation after a fault or supply break.

•

The maximum number of drive power-ups is five in ten minutes. Too frequent power-

ups can damage the charging circuit of the DC capacitors.

•

Make sure that any safety circuits (for example, emergency stop and Safe torque off)

are validated in start-up. See chapter

for reference of the validation

instructions.

Note:

•

If you select an external source for start command and it is on, the drive will start

immediately after fault reset unless you configure the drive for pulse start. See the

firmware manual.

•

When the control location is not set to Local, the stop key on the control panel will not

stop the drive.

3AUA0000088632

Summary of Contents for ACS880-07XT Series

Page 1: ...ABB industrial drives Hardware manual ACS880 07XT drives 400 to 1200 kW ...

Page 4: ......

Page 12: ...12 ...

Page 20: ...20 Safety instructions ...

Page 26: ...26 Introduction to the manual ...

Page 54: ...54 Mechanical installation ...

Page 89: ...Electrical installation 89 PE 11 8 4 9 11 ...

Page 94: ...94 Electrical installation ...

Page 112: ...112 Fault tracing ...

Page 123: ...Maintenance 123 5 6 7 ...

Page 124: ...124 Maintenance 8 10 9 ...

Page 126: ...126 Maintenance 6 5 4 ...

Page 127: ...Maintenance 127 9 8 7 ...

Page 128: ...128 Maintenance 12 11 10 ...

Page 149: ...Dimensions 149 Dimension drawing examples Frame 2 R11 R10 with brake chopper ...

Page 150: ...150 Dimensions Frame 2 R11 R10 without brake chopper ...

Page 153: ...Dimensions 153 Location of input terminals ACS880 07XT 12 pulse ...

Page 154: ...154 Dimensions Location of output terminals ACS880 07XT R10 with du dt ...

Page 155: ...Dimensions 155 Location of output terminals ACS880 07XT R10 without du dt ...

Page 156: ...156 Dimensions Location of output terminals ACS880 07XT R11 with du dt ...

Page 157: ...Dimensions 157 Location of output terminals ACS880 07XT R11 without du dt ...

Page 158: ...158 Dimensions Location of PE terminals ACS880 07XT ...

Page 159: ...Dimensions 159 Location of resistor terminals ACS880 07XT R10 ...

Page 160: ...160 Dimensions Location of resistor terminals ACS880 07XT R11 ...

Page 168: ...www abb com drives www abb com drivespartners 3ABD00043579 Rev C EN 2018 01 01 Contact us ...