Hardware

58 of 70

Hardware R2.2.8 11.98.02 en

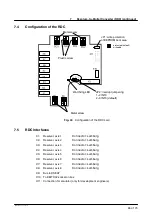

6.4

DSEAT functions

Actual position sensing:

Resolvers are used as the encoders for position sensing. The encoder signals are conditio-

ned on the RDC module. The DSEAT then receives the actual position values via a serial

interface in the form of digital signals transmitted at the rate of the position controller clock

(2 ms), i.e. the actual values are delivered as discrete numbers.

Absolute pos. = absolute pos. + partial actual value (refreshed every 2 ms)

Position control:

Closed--loop position control is implemented digitally (i.e. in the software). The difference

between the programmed position (signalled by the main processor) and the actual position

value (signalled by the RDC) is calculated. This difference is the ”following error”. Position

control is implemented on the DSEAT, in order to relieve the load on the main processor.

Speed controller:

This controller corrects the motor speed. The actual speed (i.e. the instantaneous value of

the motor speed) can be calculated from the difference between the last two actual position

values (from the RDC). The speed setpoint is calculated from:

Following error x position controller gain + speed precontrol.

Commutation:

The output from the speed controller must be multiplied by a sinusoidal function (sine of the

motor position) in order to ensure that the output voltage is in correct phase sequence relative

to the rotor position. The instantaneous rotor position can also be calculated from the actual

position value. This calculation must be performed for 2 phases. The result gives the actual

current intensity for phases U and W. These two values (per axis) are transmitted in digital

form to the PM6 via a parallel interface.

Содержание KR C1

Страница 1: ...Hardware R2 2 8 11 98 02 en 1 of 70 SOFTWARE KR C1 Hardware Release 2 2...

Страница 30: ...Hardware 30 of 70 Hardware R2 2 8 11 98 02 en Fig 13 Circuit diagram X931 X604...

Страница 31: ...4 Individual axis switch off for external axes continued 31 of 70 Hardware R2 2 8 11 98 02 en Fig 14 Outputs...

Страница 32: ...Hardware 32 of 70 Hardware R2 2 8 11 98 02 en Fig 15 Inputs...

Страница 34: ...Hardware 34 of 70 Hardware R2 2 8 11 98 02 en...

Страница 35: ...35 of 70 Hardware R2 2 8 11 98 02 en...

Страница 55: ...55 of 70 Hardware R2 2 8 11 98 02 en...