HYBRID/TROUBLE SHOOTING

3–216

4

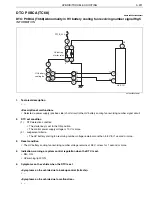

Inspecting the

coolant tem-

perature sen-

sor

1. Set the starter key to the

"LOCK" position.

2. Disconnect the connector of

coolant temperature sensor.

3. Using the electrical tester, mea-

sure the resistance between

the terminals of coolant tem-

perature sensor connector.

<Measurement conditions>

Starter key: LOCK

<Tester connections>

Coolant temperature sensor con-

nector (sensor side)

1st terminal

–

2nd terminal

<Standard values>

0

C {32

F}: 5.3 k

–

6.2 k

20

C {68

F}: 2.3 k

–

2.6 k

30

C {86

F}: 1.5 k

–

1.8 k

The mea-

sured value is

within the

range of stan-

dard value: Go

to YES.

The mea-

sured value is

not within the

range of stan-

dard value: Go

to NO.

Go to step 5.

Replace the

coolant tem-

perature sen-

sor.

5

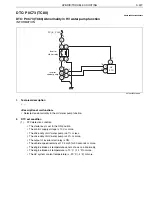

Inspecting the

signal line of

PCU wire har-

ness (lower

side) for short

circuit

1. For the 2nd terminal of coolant

temperature sensor connector,

inspect the signal line of PCU

wire harness (lower side) for

short circuit. (See "Inspecting

the PCU harness signal line for

short circuit.")

<Measurement conditions>

Starter key: LOCK

<Tester connections>

Coolant temperature sensor con-

nector

2nd terminal

–

Each signal line

<Standard values>

10 k

or more

Defect is

found: Go to

YES.

Defect is not

found: Go to

NO.

Replace the

PCU wire har-

ness (lower

side).

Go to step 6.

6

Reproduction

check [HINO-

DX]

1. Connect all the connectors that

have been disconnected to

restore the system.

2. Connect the diagnosis tool

(HINO-DX) to the vehicle.

3. Set the starter key to the "ON"

position.

4. Clear the malfunction history.

5. Perform a test run for approxi-

mately 30 minutes.

6. In [Fault Information] on the

diagnosis tool screen, check if

P0A93-7A is detected.

DTC P0A93-

7A is detected:

Go to YES.

DTC P0A93-

7A is not

detected: Go

to NO.

Replace the

HV ECU.

The inspec-

tion is com-

pleted.

P0A93 (TC7A)

Abnormality in inverter cooling system

Inspection Procedure

Step

Action

Description

Judgement

Check

(Yes/No)

Yes

No