SS1807-N002

Checkup, Replacement and Adjustment

-

135/137

◆

Note

◆

・

In case the numerical value is beyond the specified limits, turn the dial of the manual binding

tool to adjust.

(6) Discard the cut cable tie.

(7) Repeat Steps (3) to (6) until the numerical value stays within the specified limits for 3 times

running.

2) Evaluation

(1) Should be within a range of -35 N to -45 N for 3 times running.

3.3.3 Electrical safety test/the plug and play force measurement jig

3.3.3.1

Interterminal Resistance Value

1) Procedure

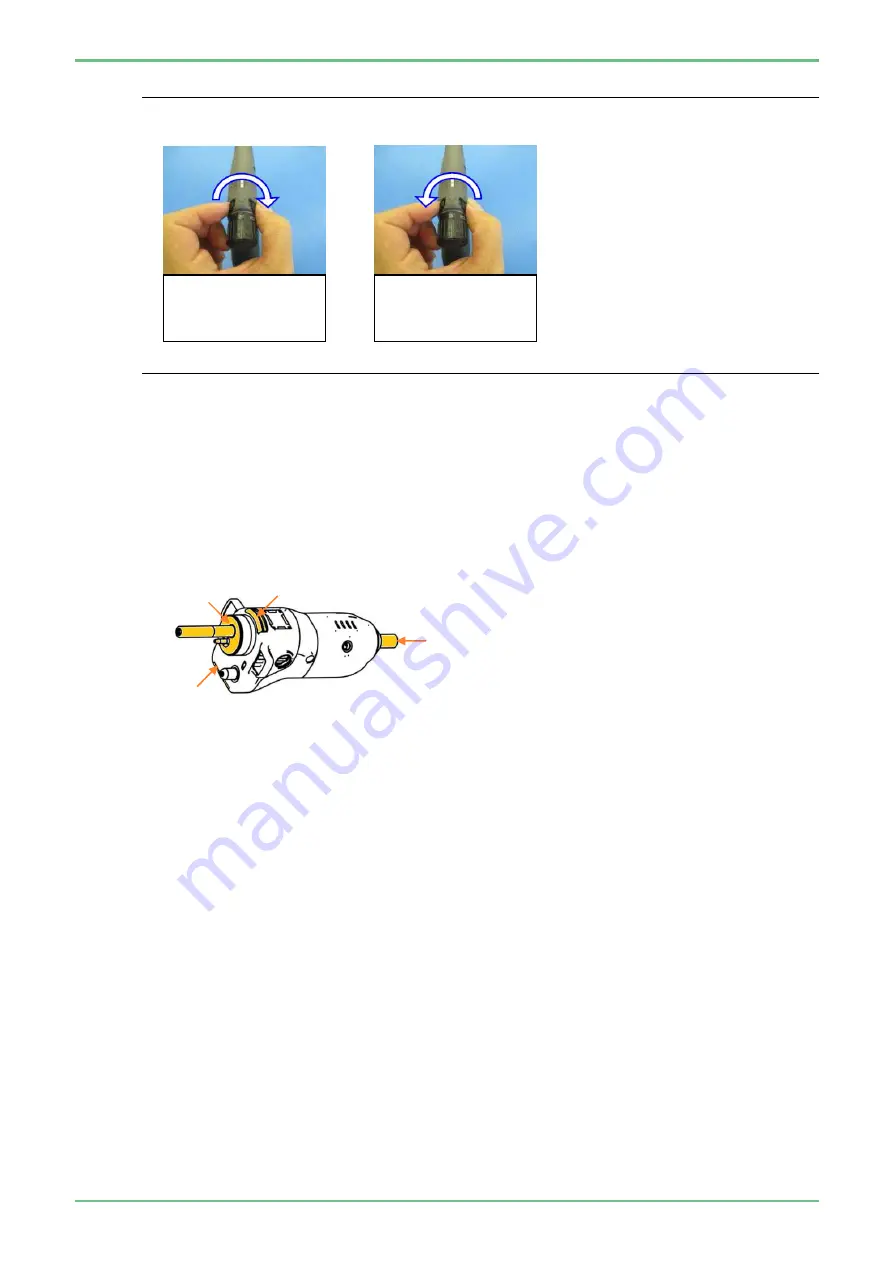

(1) Use the tester to measure a resistance value between the respective terminals a, b, c and d.

2) Evaluation

(1) Should be 1

Ω or less.

3.3.4 Protective earth power cable jig

3.3.4.1 Resistance Value

1) Procedure

(1) Measure a resistance value between the probes of the tester.

⇒

Measured value: A

(2) Measure a resistance value between the AC cable socket (GND) and the terminal of the

protective earth power cable jig.

⇒

Measured value: B

2) Evaluation

(1) Should be B – A

≤

0.05

Ω

.

a

b

c

d

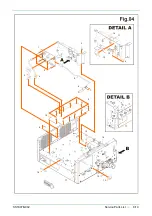

When pulling force

is weaker than the

specification limit

When pulling force

is stronger than the

specification limit

Содержание EP-6000

Страница 1: ...Processor EP 6000 FV693A Service Manual SR1807 N002 Ver 1 Oct 2018 ...

Страница 5: ...SS1807 N002 General Table of Contents 1 1 General Table of Contents ...

Страница 13: ...SS1807 N002 Caution in Safety 1 12 Caution in Safety ...

Страница 18: ...SS1807 N002 Caution in Safety 6 12 2 Label 2 1 EP 6000 Labeling Layout FV693A 2 1 1 Labeling chart D B A C ...

Страница 25: ...SS1807 N002 Product Specifications 1 11 Product Specifications ...

Страница 36: ...SS1807 N002 Instruction of System 1 106 Instruction of System ...

Страница 52: ...SS1807 N002 Instruction of System 17 106 In the case of Normal mode In the case of BLI BLI bright or LCI ...

Страница 131: ...SS1807 N002 Instruction of System 96 106 9 EP 6000 Description of Configuration 9 1 Block Diagram ...

Страница 133: ...SS1807 N002 Instruction of System 98 106 ELC PCB Patient PCB APC PCB APC PCB APC PCB DC Pump ...

Страница 139: ...SS1807 N002 Instruction of System 104 106 9 4 Outline of PCB roles ...

Страница 142: ...SS1807 N002 Failure Analysis 1 64 Failure Analysis ...

Страница 206: ...SS1807 N002 Checkup Replacement and Adjustment 1 137 Checkup Replacement and Adjustment ...

Страница 343: ...SS1807 N002 Service Parts List 1 19 Service Parts List ...

Страница 348: ...SS1807 N002 Service Parts List 6 19 6 13 13 16 18 17 17 6 18 14 15 6 9 10 6 12 7 6 11 8 6 5 1 4 3 2 ...

Страница 350: ...SS1807 N002 Service Parts List 8 19 13 12 14 11 14 17 7 7 2 6 15 7 2 3 4 1 5 2 10 9 17 7 7 8 18 12 13 16 ...

Страница 352: ...SS1807 N002 Service Parts List 10 19 2 2 2 4 1 3 3 2 3 3 6 5 ...

Страница 356: ...SS1807 N002 Service Parts List 14 19 1 3 3 4 1 2 1 3 X 4 1 3 3 4 3 3 ...

Страница 358: ...SS1807 N002 Service Parts List 16 19 3 1 2 1 ...

Страница 360: ...SS1807 N002 Service Parts List 18 19 Fig 09 5 4 2 3 1 ...

Страница 362: ...SS1807 N002 Periodical Maintenance 1 15 Periodical Maintenance ...

Страница 377: ...SS1807 N002 Installation 1 68 Installation ...

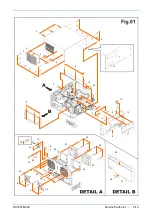

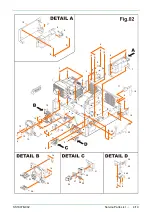

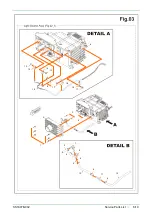

Страница 381: ...SS1807 N002 Installation 5 68 1 2 Installation onto the Cart Standard System Installation Example ...

Страница 445: ...SS1807 N002 ...