SS1807-N002

Failure Analysi

-

39/64

Display

error

code

Classification

level

Display message

(occurrence, response)

Display message

(guidance to

error)

Estimated cause

Trigger of message display

Service response

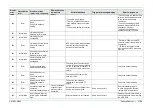

20015

Warning

Connected scope cannot

be used.

A non-compliant scope was

connected and startup or

inspection start was executed

Same as on the left

In case of repetitive failures

applicable scopes, replace the

scope (prototypes or scopes for

overseas may have unexpected

IDs

)

and the patient PCB.

20016

Warning

Scope is turned off.

Execute scope installation

during the standby state.

Performed scope CPU

installation with the scope not

turned ON.

Same as on the left

In case of repetitive failures in

spite of inspectable condition,

replace the patient PCB and the

main PCB..

20017

Warning

The power is turned off

while saving the result of

scope color adjustment.

Execute scope color

adjustment again.

Power turned OFF during writing

in for scope color adjustment.

After the same as on the left,

whenever starting up till the

scope color adjustment results

have been properly saved

In case of repetitive failures even

if scope color adjustment was

tried again, replace the main

PCB.

20018

Warning

Examination cannot be

started because two

scopes are inserted.

When the examination button

was pressed, both of the 2

connectors were set.

Same as on the left

In case of repetitive failures even

if the scope is not connected to

both of the 2 connectors, replace

the scope connector and the

patient PCB.

20021

Error

Update of scope CPU

failed.

400-series scopes cannot

be updated.

A scope update was performed

while a 400-series scope was

connected.

Same as on the left

Updating of a 400-series scope is

not possible and must therefore

not be executed.

20022

Warning

Automatic color

adjustment cannot be

executed with this scope.

A 400-series scope with no AWB

support was connected.

When auto color adjustment is

executed while a 400-series

scope with no AWB support is

connected.

In case of repetitive failures in a

scope that supports AWB

execution, replace the patient

PCB and main PCB and inspect

the scope.

20023

Warning

Unplug and plug back

endoscope, reset the

processor. If the problem

persists, contact your

local FUJIFILM dealer.

Cause:

Initialization of

endoscope failed.

The scope could not be initialized

due to communication noise.

When a system startup or

inspection is started while a

400-series scope is connected.

In case of repetitive failures,

replace the EVE connector, the

scope, and the patient PCB.

20024

Warning

Two scopes are inserted.

End examination and

connect the cap to the

connector not to be used.

A second scope was connected

during inspection.

Same as on the left

In case of repetitive failures in

spite of the second scope not

being connected, replace the

scope connector, the scope, and

the patient PCB.

Содержание EP-6000

Страница 1: ...Processor EP 6000 FV693A Service Manual SR1807 N002 Ver 1 Oct 2018 ...

Страница 5: ...SS1807 N002 General Table of Contents 1 1 General Table of Contents ...

Страница 13: ...SS1807 N002 Caution in Safety 1 12 Caution in Safety ...

Страница 18: ...SS1807 N002 Caution in Safety 6 12 2 Label 2 1 EP 6000 Labeling Layout FV693A 2 1 1 Labeling chart D B A C ...

Страница 25: ...SS1807 N002 Product Specifications 1 11 Product Specifications ...

Страница 36: ...SS1807 N002 Instruction of System 1 106 Instruction of System ...

Страница 52: ...SS1807 N002 Instruction of System 17 106 In the case of Normal mode In the case of BLI BLI bright or LCI ...

Страница 131: ...SS1807 N002 Instruction of System 96 106 9 EP 6000 Description of Configuration 9 1 Block Diagram ...

Страница 133: ...SS1807 N002 Instruction of System 98 106 ELC PCB Patient PCB APC PCB APC PCB APC PCB DC Pump ...

Страница 139: ...SS1807 N002 Instruction of System 104 106 9 4 Outline of PCB roles ...

Страница 142: ...SS1807 N002 Failure Analysis 1 64 Failure Analysis ...

Страница 206: ...SS1807 N002 Checkup Replacement and Adjustment 1 137 Checkup Replacement and Adjustment ...

Страница 343: ...SS1807 N002 Service Parts List 1 19 Service Parts List ...

Страница 348: ...SS1807 N002 Service Parts List 6 19 6 13 13 16 18 17 17 6 18 14 15 6 9 10 6 12 7 6 11 8 6 5 1 4 3 2 ...

Страница 350: ...SS1807 N002 Service Parts List 8 19 13 12 14 11 14 17 7 7 2 6 15 7 2 3 4 1 5 2 10 9 17 7 7 8 18 12 13 16 ...

Страница 352: ...SS1807 N002 Service Parts List 10 19 2 2 2 4 1 3 3 2 3 3 6 5 ...

Страница 356: ...SS1807 N002 Service Parts List 14 19 1 3 3 4 1 2 1 3 X 4 1 3 3 4 3 3 ...

Страница 358: ...SS1807 N002 Service Parts List 16 19 3 1 2 1 ...

Страница 360: ...SS1807 N002 Service Parts List 18 19 Fig 09 5 4 2 3 1 ...

Страница 362: ...SS1807 N002 Periodical Maintenance 1 15 Periodical Maintenance ...

Страница 377: ...SS1807 N002 Installation 1 68 Installation ...

Страница 381: ...SS1807 N002 Installation 5 68 1 2 Installation onto the Cart Standard System Installation Example ...

Страница 445: ...SS1807 N002 ...