SS1807-N002

Checkup, Replacement and Adjustment

-

113/137

No.

Inspection items

Inspection specification

How to inspect

Remarks

3

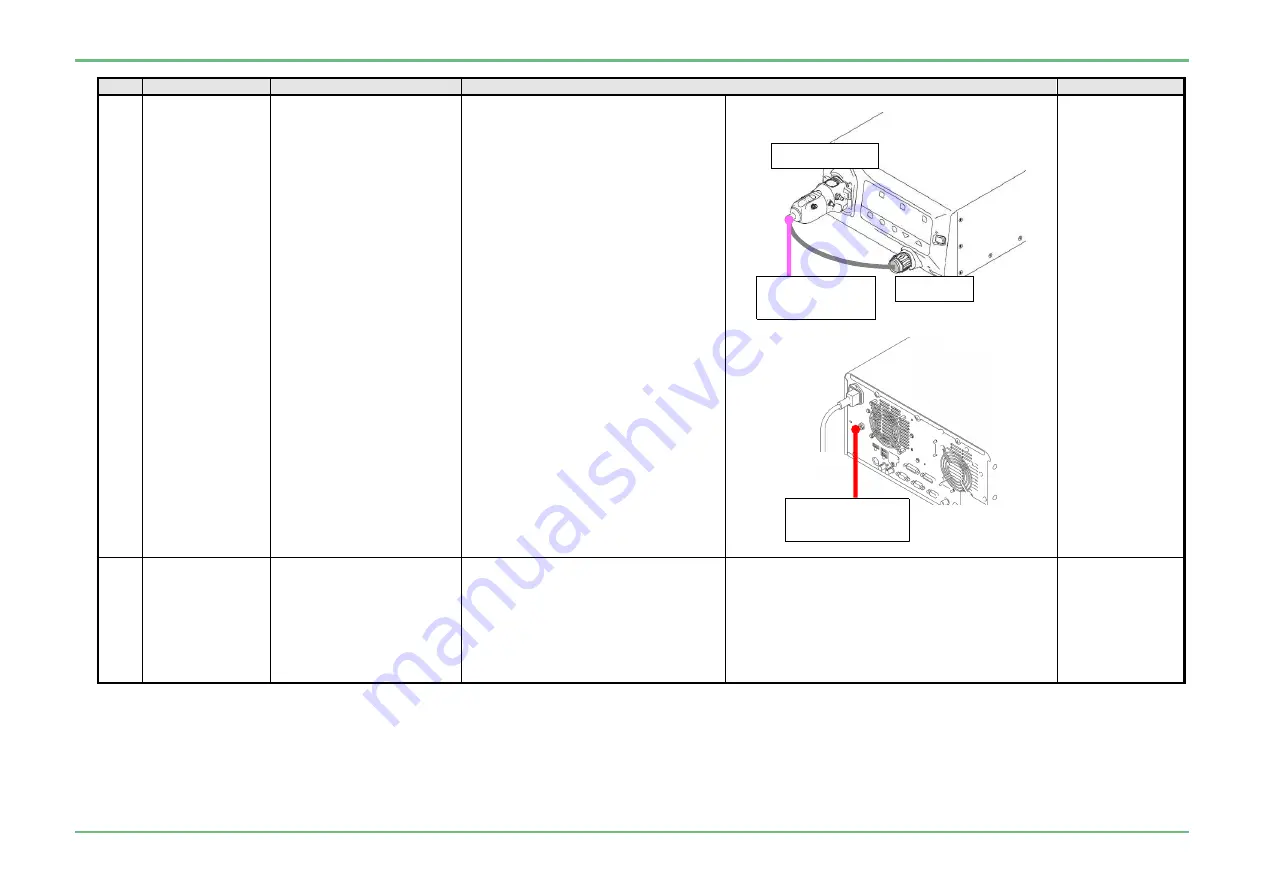

4)Patient leakage

current III

Single fault

condition

The value should be below

the value shown in [Table 5].

1) Set the test voltage to the power input

and frequency in [Table 4].

2) Connect the “842Y130002*” jig and

“J57722” jig to the processor

3) Connect the probe on applied voltage

side of the leakage current tester to the

“842Y130002*” jig and the “J57722” jig.

4) Connect the probe on leakage current

tester to the "potential equalization

terminal"

(Not necessary if the tester using the

earth Pin of power plug is used for

measurement.)

5) Turn ON the power to the device to be

measured and leave as is for 5

minutes or more.

6) Apply the test voltage and read the

leakage current value in each state.

7) Return the applied voltage to 0V, and

disconnect all cables.

* The measurement condition refers to

[Table 5].

JIG/Equipment

・

Leakage current

tester

・

842Y130002*

・

J57722

4

Electric current

Must be +10% or less in

relation to the center of the

specification of [Table 4].

1) Set the test voltage to the power input

and frequency in [Table 6].

2) Connect the 760 scope and each

signal output, and turn ON the power.

3) Set the light quantity to MAX and the

pump to high, leave in this state for 1

minute, and read the electric current

value.

JIG/Equipment

・

760 Scope

J57722

Probe on applied

voltage side

842Y130002*

Probe on leakage

current

tester

Содержание EP-6000

Страница 1: ...Processor EP 6000 FV693A Service Manual SR1807 N002 Ver 1 Oct 2018 ...

Страница 5: ...SS1807 N002 General Table of Contents 1 1 General Table of Contents ...

Страница 13: ...SS1807 N002 Caution in Safety 1 12 Caution in Safety ...

Страница 18: ...SS1807 N002 Caution in Safety 6 12 2 Label 2 1 EP 6000 Labeling Layout FV693A 2 1 1 Labeling chart D B A C ...

Страница 25: ...SS1807 N002 Product Specifications 1 11 Product Specifications ...

Страница 36: ...SS1807 N002 Instruction of System 1 106 Instruction of System ...

Страница 52: ...SS1807 N002 Instruction of System 17 106 In the case of Normal mode In the case of BLI BLI bright or LCI ...

Страница 131: ...SS1807 N002 Instruction of System 96 106 9 EP 6000 Description of Configuration 9 1 Block Diagram ...

Страница 133: ...SS1807 N002 Instruction of System 98 106 ELC PCB Patient PCB APC PCB APC PCB APC PCB DC Pump ...

Страница 139: ...SS1807 N002 Instruction of System 104 106 9 4 Outline of PCB roles ...

Страница 142: ...SS1807 N002 Failure Analysis 1 64 Failure Analysis ...

Страница 206: ...SS1807 N002 Checkup Replacement and Adjustment 1 137 Checkup Replacement and Adjustment ...

Страница 343: ...SS1807 N002 Service Parts List 1 19 Service Parts List ...

Страница 348: ...SS1807 N002 Service Parts List 6 19 6 13 13 16 18 17 17 6 18 14 15 6 9 10 6 12 7 6 11 8 6 5 1 4 3 2 ...

Страница 350: ...SS1807 N002 Service Parts List 8 19 13 12 14 11 14 17 7 7 2 6 15 7 2 3 4 1 5 2 10 9 17 7 7 8 18 12 13 16 ...

Страница 352: ...SS1807 N002 Service Parts List 10 19 2 2 2 4 1 3 3 2 3 3 6 5 ...

Страница 356: ...SS1807 N002 Service Parts List 14 19 1 3 3 4 1 2 1 3 X 4 1 3 3 4 3 3 ...

Страница 358: ...SS1807 N002 Service Parts List 16 19 3 1 2 1 ...

Страница 360: ...SS1807 N002 Service Parts List 18 19 Fig 09 5 4 2 3 1 ...

Страница 362: ...SS1807 N002 Periodical Maintenance 1 15 Periodical Maintenance ...

Страница 377: ...SS1807 N002 Installation 1 68 Installation ...

Страница 381: ...SS1807 N002 Installation 5 68 1 2 Installation onto the Cart Standard System Installation Example ...

Страница 445: ...SS1807 N002 ...