SS1807-N002

Checkup, Replacement and Adjustment

-

112/137

No.

Inspection items

Inspection specification

How to inspect

Remarks

3

1) Earth leakage

current

The value should be below

the value shown in [Table 5].

1) Set the test voltage to the power input

and frequency in [Table 4].

2) Disconnect all output cables.

3) Turn ON the power to the device to be

measured, stop the pump, and leave in

this state for more than 5 minutes.

4) Read the leakage current value in

each state.

*The measurement condition refers to

[Table 5].

JIG/Equipment

・

Leakage current

tester

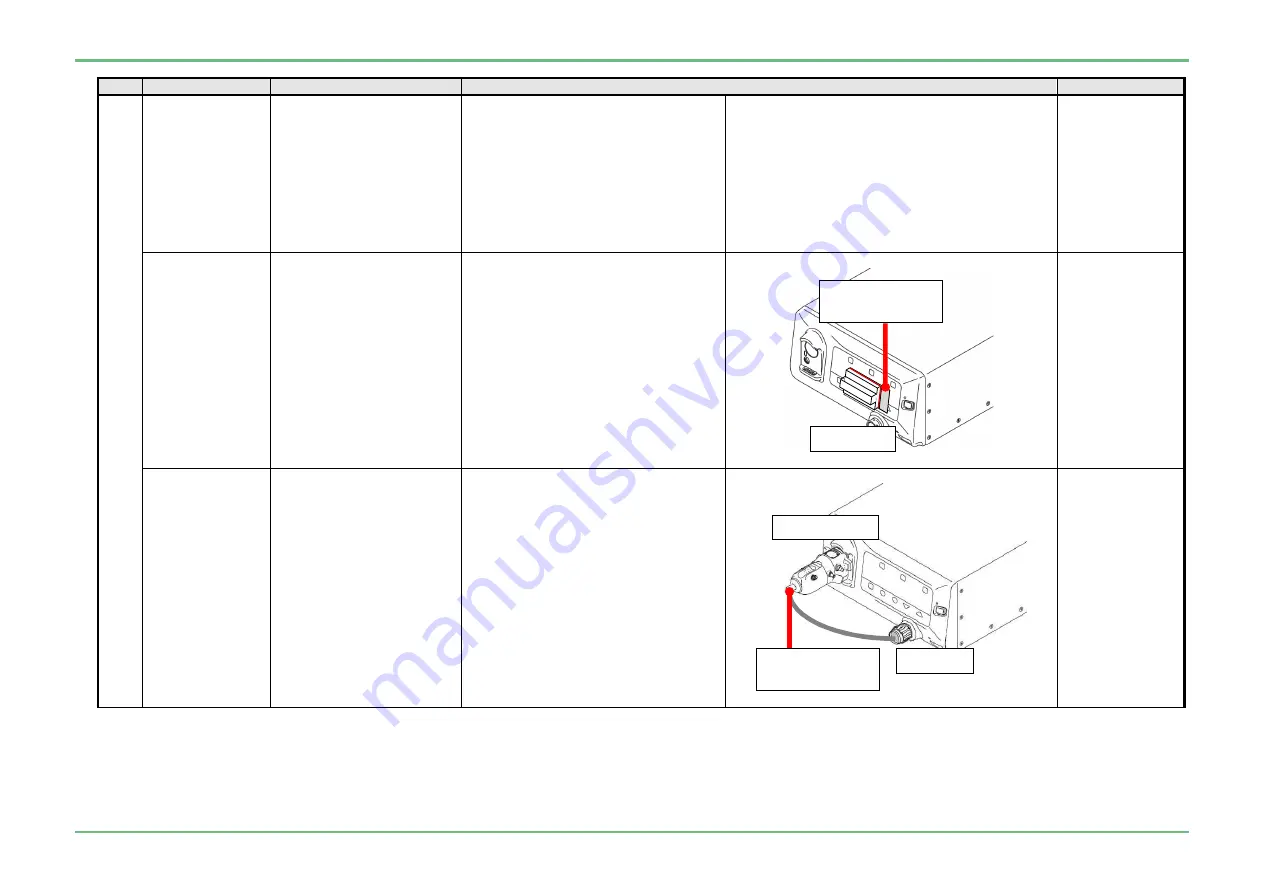

2) Enclosure

leakage current

The value should be below

the value shown in [Table 5].

1) Set the test voltage to the power input

and frequency in [Table 4].

2) Disconnect all output cables.

3) Turn ON the power to the device to be

measured, stop the pump, and leave in

this state for more than 5 minutes.

4) Apply the enclosure leakage current

test Jig “Y11N034” to the operation

panel, connect the probe of the leakage

current tester, and read the leakage

current value in each state.

*The measurement condition refers to

[Table 5].

JIG/Equipment

・

Leakage current

tester

3) Patient leakage

current I

The value should be below

the value shown in [Table 5].

1) Set the test voltage to the power input

and frequency in [Table 4].

2) Disconnect all output cables.

3) Connect the “842Y130002*” jig and

“J57722” jig to the processor

4) Connect the probe on leakage current

tester to the “842Y130002*” jig and the

“J57722” jig.

5) Turn ON the power to the device to be

measured, stop the pump, and leave in

this state for more than 5 minutes.

6) Read the leakage current value in

each state.

*The measurement condition refers to

[Table 5]

JIG/Equipment

・

Leakage current

tester

・

842Y130002*

・

J57722

J57722

Probe on leakage

current tester

842Y130002*

Y11N0346

Probe on leakage

current tester

Содержание EP-6000

Страница 1: ...Processor EP 6000 FV693A Service Manual SR1807 N002 Ver 1 Oct 2018 ...

Страница 5: ...SS1807 N002 General Table of Contents 1 1 General Table of Contents ...

Страница 13: ...SS1807 N002 Caution in Safety 1 12 Caution in Safety ...

Страница 18: ...SS1807 N002 Caution in Safety 6 12 2 Label 2 1 EP 6000 Labeling Layout FV693A 2 1 1 Labeling chart D B A C ...

Страница 25: ...SS1807 N002 Product Specifications 1 11 Product Specifications ...

Страница 36: ...SS1807 N002 Instruction of System 1 106 Instruction of System ...

Страница 52: ...SS1807 N002 Instruction of System 17 106 In the case of Normal mode In the case of BLI BLI bright or LCI ...

Страница 131: ...SS1807 N002 Instruction of System 96 106 9 EP 6000 Description of Configuration 9 1 Block Diagram ...

Страница 133: ...SS1807 N002 Instruction of System 98 106 ELC PCB Patient PCB APC PCB APC PCB APC PCB DC Pump ...

Страница 139: ...SS1807 N002 Instruction of System 104 106 9 4 Outline of PCB roles ...

Страница 142: ...SS1807 N002 Failure Analysis 1 64 Failure Analysis ...

Страница 206: ...SS1807 N002 Checkup Replacement and Adjustment 1 137 Checkup Replacement and Adjustment ...

Страница 343: ...SS1807 N002 Service Parts List 1 19 Service Parts List ...

Страница 348: ...SS1807 N002 Service Parts List 6 19 6 13 13 16 18 17 17 6 18 14 15 6 9 10 6 12 7 6 11 8 6 5 1 4 3 2 ...

Страница 350: ...SS1807 N002 Service Parts List 8 19 13 12 14 11 14 17 7 7 2 6 15 7 2 3 4 1 5 2 10 9 17 7 7 8 18 12 13 16 ...

Страница 352: ...SS1807 N002 Service Parts List 10 19 2 2 2 4 1 3 3 2 3 3 6 5 ...

Страница 356: ...SS1807 N002 Service Parts List 14 19 1 3 3 4 1 2 1 3 X 4 1 3 3 4 3 3 ...

Страница 358: ...SS1807 N002 Service Parts List 16 19 3 1 2 1 ...

Страница 360: ...SS1807 N002 Service Parts List 18 19 Fig 09 5 4 2 3 1 ...

Страница 362: ...SS1807 N002 Periodical Maintenance 1 15 Periodical Maintenance ...

Страница 377: ...SS1807 N002 Installation 1 68 Installation ...

Страница 381: ...SS1807 N002 Installation 5 68 1 2 Installation onto the Cart Standard System Installation Example ...

Страница 445: ...SS1807 N002 ...