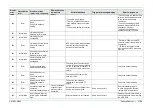

SS1807-N002

Failure Analysi

-

38/64

Display

error

code

Classification

level

Display message

(occurrence, response)

Display message

(guidance to

error)

Estimated cause

Trigger of message display

Service response

20004

Information

Executing scope color

auto adjustment.

Please wait for a while.

“Execute Auto Adjust” was

selected on the scope color auto

adjustment screen.

Same as on the left

If the message does not

disappear after a while, restart

the processor, and do it again.

In case of repetitive failures,

replace the scope and the patient

PCB.

20007

Warning

Scope color auto

adjustment ends

abnormally.

(1) The scope color auto

adjustment could not be set

within the allowable range.

(2) The provided jig (an

integrating sphere) was not used.

At the time of making scope color

auto adjustment

In case of repetitive failures in

spite of having made the

adjustment again, replace the

scope. In case of more

repetitive failures, replace the

patient PCB.

20008

Information

Scope colors are reset to

factory defaults.

When writing data to

EEPROM, perform

"Execute Writing".

“Reset to factory defaults” was

selected on the scope color auto

/ manual adjustment screen, and

scope colors were reset normally

to factory defaults.

Same as on the left

“Execute Writing” is additionally

required in order to write data in

EEPROM.

20009

Error

Unplug and plug back

endoscope, reset the

processor. If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The

processor is in

abnormal state.

“Reset to factory defaults” was

selected on the scope color auto

/ manual adjustment screen, and

scope color resetting to factory

defaults failed.

Same as on the left

In case of repetitive failures,

replace the main PCB and the

patient PCB.

20011

Information

Writing scope color

settings is completed.

“Execute Writing” was selected

on the scope color auto/manual

adjustment screen, and the

writing-in operation ended

normally.

Same as on the left

20012

Error

Unplug and plug back

endoscope, reset the

processor. If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The

processor is in

abnormal state.

“Execute Writing” was selected

on the scope color auto/manual

adjustment screen, and the

writing-in operation failed.

Same as on the left

In case of repetitive failures,

replace the main PCB and the

patient PCB.

20013

Warning

To end examination,

press the scope button for

more than 1 second.

During examination, pressed the

examination button, and released

it in less than 1 second.

Same as on the left

In case of display with the button

being pressed for more than 1

second, replace the front panel

and the main PCB.

20014

Information

Initializing optical zoom.

Please wait for a while.

After start of examination, or after

having changed the optical zoom

speed, when the optical zoom

button was pressed for the first

time

Same as on the left

If the message does not

disappear after a while, replace

the scope.

Содержание EP-6000

Страница 1: ...Processor EP 6000 FV693A Service Manual SR1807 N002 Ver 1 Oct 2018 ...

Страница 5: ...SS1807 N002 General Table of Contents 1 1 General Table of Contents ...

Страница 13: ...SS1807 N002 Caution in Safety 1 12 Caution in Safety ...

Страница 18: ...SS1807 N002 Caution in Safety 6 12 2 Label 2 1 EP 6000 Labeling Layout FV693A 2 1 1 Labeling chart D B A C ...

Страница 25: ...SS1807 N002 Product Specifications 1 11 Product Specifications ...

Страница 36: ...SS1807 N002 Instruction of System 1 106 Instruction of System ...

Страница 52: ...SS1807 N002 Instruction of System 17 106 In the case of Normal mode In the case of BLI BLI bright or LCI ...

Страница 131: ...SS1807 N002 Instruction of System 96 106 9 EP 6000 Description of Configuration 9 1 Block Diagram ...

Страница 133: ...SS1807 N002 Instruction of System 98 106 ELC PCB Patient PCB APC PCB APC PCB APC PCB DC Pump ...

Страница 139: ...SS1807 N002 Instruction of System 104 106 9 4 Outline of PCB roles ...

Страница 142: ...SS1807 N002 Failure Analysis 1 64 Failure Analysis ...

Страница 206: ...SS1807 N002 Checkup Replacement and Adjustment 1 137 Checkup Replacement and Adjustment ...

Страница 343: ...SS1807 N002 Service Parts List 1 19 Service Parts List ...

Страница 348: ...SS1807 N002 Service Parts List 6 19 6 13 13 16 18 17 17 6 18 14 15 6 9 10 6 12 7 6 11 8 6 5 1 4 3 2 ...

Страница 350: ...SS1807 N002 Service Parts List 8 19 13 12 14 11 14 17 7 7 2 6 15 7 2 3 4 1 5 2 10 9 17 7 7 8 18 12 13 16 ...

Страница 352: ...SS1807 N002 Service Parts List 10 19 2 2 2 4 1 3 3 2 3 3 6 5 ...

Страница 356: ...SS1807 N002 Service Parts List 14 19 1 3 3 4 1 2 1 3 X 4 1 3 3 4 3 3 ...

Страница 358: ...SS1807 N002 Service Parts List 16 19 3 1 2 1 ...

Страница 360: ...SS1807 N002 Service Parts List 18 19 Fig 09 5 4 2 3 1 ...

Страница 362: ...SS1807 N002 Periodical Maintenance 1 15 Periodical Maintenance ...

Страница 377: ...SS1807 N002 Installation 1 68 Installation ...

Страница 381: ...SS1807 N002 Installation 5 68 1 2 Installation onto the Cart Standard System Installation Example ...

Страница 445: ...SS1807 N002 ...