SS1807-N002

Failure Analysi

-

50/64

Display

error

code

Classification

level

Display message

(occurrence, response)

Display message

(guidance to

error)

Estimated cause

Trigger of message display

Service response

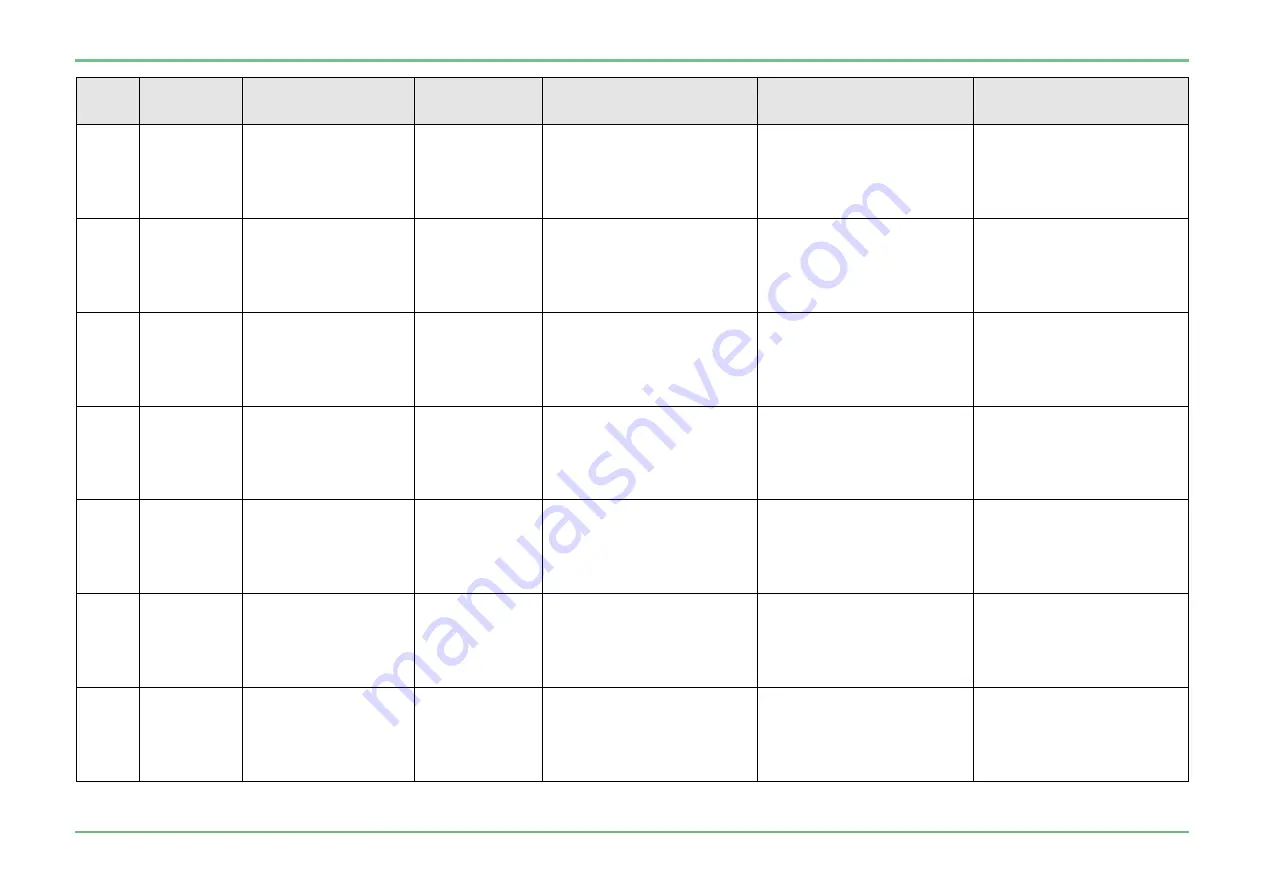

30137

Warning

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: LD low temperature error

was detected in light source.

Brightness control was activated

and re-lighting was inhibited.

At detection of temperature error

in LL-7000 light source

Wait until LD temperature is

raised.

Replace the light source if not

improved.

30138

Warning

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: LD high temperature

error was detected in light

source.

Brightness control was activated

and re-lighting was inhibited.

At detection of temperature error

in LL-7000 light source

Wait until LD temperature is

lowered.

Replace the light source if not

improved.

30139

Warning

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

(CODE =

0x11203)

Cause: Heat sink low

temperature error was detected

in light source.

At detection of temperature error

in LL-7000 light source

Wait until LD temperature is

raised.

Replace the light source if not

improved.

30140

Warning

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

(CODE =

0x11204)

Cause: Heat sink high

temperature error was detected

in light source.

At detection of temperature error

in LL-7000 light source

Wait until LD temperature is

lowered.

Replace the light source if not

improved.

30141

Warning

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: Cooling fan stop error

was detected in light source.

This is only a warning and

operation is not limited.

At detection of hardware error in

LL-7000 light source

No emergency response is

required.

(It will eventually become LD

temperature error.)

30143

Warning

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Code error of LD PCB (excluding

standard LD drive PCB) was

detected at light source startup.

This is only a warning and

operation is not limited. However,

normal operation is not ensured.

At detection of hardware error in

LL-7000 light source

Replace the light source.

30144

Warning

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: EEPROM readout error

was detected in light source.

This is only a warning and

operation is not limited. However,

normal operation is not ensured.

At detection of hardware error in

LL-7000 light source

Replace the light source.

Содержание EP-6000

Страница 1: ...Processor EP 6000 FV693A Service Manual SR1807 N002 Ver 1 Oct 2018 ...

Страница 5: ...SS1807 N002 General Table of Contents 1 1 General Table of Contents ...

Страница 13: ...SS1807 N002 Caution in Safety 1 12 Caution in Safety ...

Страница 18: ...SS1807 N002 Caution in Safety 6 12 2 Label 2 1 EP 6000 Labeling Layout FV693A 2 1 1 Labeling chart D B A C ...

Страница 25: ...SS1807 N002 Product Specifications 1 11 Product Specifications ...

Страница 36: ...SS1807 N002 Instruction of System 1 106 Instruction of System ...

Страница 52: ...SS1807 N002 Instruction of System 17 106 In the case of Normal mode In the case of BLI BLI bright or LCI ...

Страница 131: ...SS1807 N002 Instruction of System 96 106 9 EP 6000 Description of Configuration 9 1 Block Diagram ...

Страница 133: ...SS1807 N002 Instruction of System 98 106 ELC PCB Patient PCB APC PCB APC PCB APC PCB DC Pump ...

Страница 139: ...SS1807 N002 Instruction of System 104 106 9 4 Outline of PCB roles ...

Страница 142: ...SS1807 N002 Failure Analysis 1 64 Failure Analysis ...

Страница 206: ...SS1807 N002 Checkup Replacement and Adjustment 1 137 Checkup Replacement and Adjustment ...

Страница 343: ...SS1807 N002 Service Parts List 1 19 Service Parts List ...

Страница 348: ...SS1807 N002 Service Parts List 6 19 6 13 13 16 18 17 17 6 18 14 15 6 9 10 6 12 7 6 11 8 6 5 1 4 3 2 ...

Страница 350: ...SS1807 N002 Service Parts List 8 19 13 12 14 11 14 17 7 7 2 6 15 7 2 3 4 1 5 2 10 9 17 7 7 8 18 12 13 16 ...

Страница 352: ...SS1807 N002 Service Parts List 10 19 2 2 2 4 1 3 3 2 3 3 6 5 ...

Страница 356: ...SS1807 N002 Service Parts List 14 19 1 3 3 4 1 2 1 3 X 4 1 3 3 4 3 3 ...

Страница 358: ...SS1807 N002 Service Parts List 16 19 3 1 2 1 ...

Страница 360: ...SS1807 N002 Service Parts List 18 19 Fig 09 5 4 2 3 1 ...

Страница 362: ...SS1807 N002 Periodical Maintenance 1 15 Periodical Maintenance ...

Страница 377: ...SS1807 N002 Installation 1 68 Installation ...

Страница 381: ...SS1807 N002 Installation 5 68 1 2 Installation onto the Cart Standard System Installation Example ...

Страница 445: ...SS1807 N002 ...