Installation manual.

CNC 8060

CNC 8065

2.

MACHINE PA

RAMETERS.

Gen

e

ral machin

e parameters.

·104·

(R

EF

: 1709)

2.3.26

Synchronized switching.

SWTOUTPUT

Local digital output associated with synchronized switching.

Possible values: From 0 to NLOCOUT (Number of local digital outputs).

Default value: 0.

Associated variable: (V.)MPG.SWTOUTPUT

Local digital output associated with synchronized switching. For synchronized switching,

only local outputs associated with pins LI/O1 (local output 1) and LI/O2 (local output 2) may

be used because they have been set for Laser applications. That requires setting parameter

NLOCOUT = 8.

Synchronized switching refers to the process to control a local digital output of the CNC

depending on the type of movement programmed on the axes. The selected digital output

is activated when switching from G0 to G1/G2/G3. The selected digital output is canceled

when switching from G1/G2/G3 to G0.

In order for this feature to work better, the parameters of the axes involved in the movements

must be set with the same values (gain, filters, acceleration and deceleration, feed forward,

etc.) and must also work with the least amount of following error (lag) as possible.

SWTDELAY

Delay of the device associated with synchronized switching.

Possible values: From 0 to 100 ms.

Default value: 0 ms.

Associated variable: (V.)MPG.SWTDELAY

This parameter sets the delay between digital output on/off and the device that is connected

to it.

SWTG0FEED

Observe the G00 feedrate during the synchronized switching.

Possible values: Yes / No.

Default value: Yes.

Associated variable: (V.)MPG.SWTG0FEED

The SWTG0FEED parameter determines the feedrate for the sections in G0.

The behavior can be modified from the part program with the instruction #SWTOUT. If

according to the parameter or the command (#SWTOUT) the G0s are executed as G1

(constant feedrate), G0 is displayed in the history.

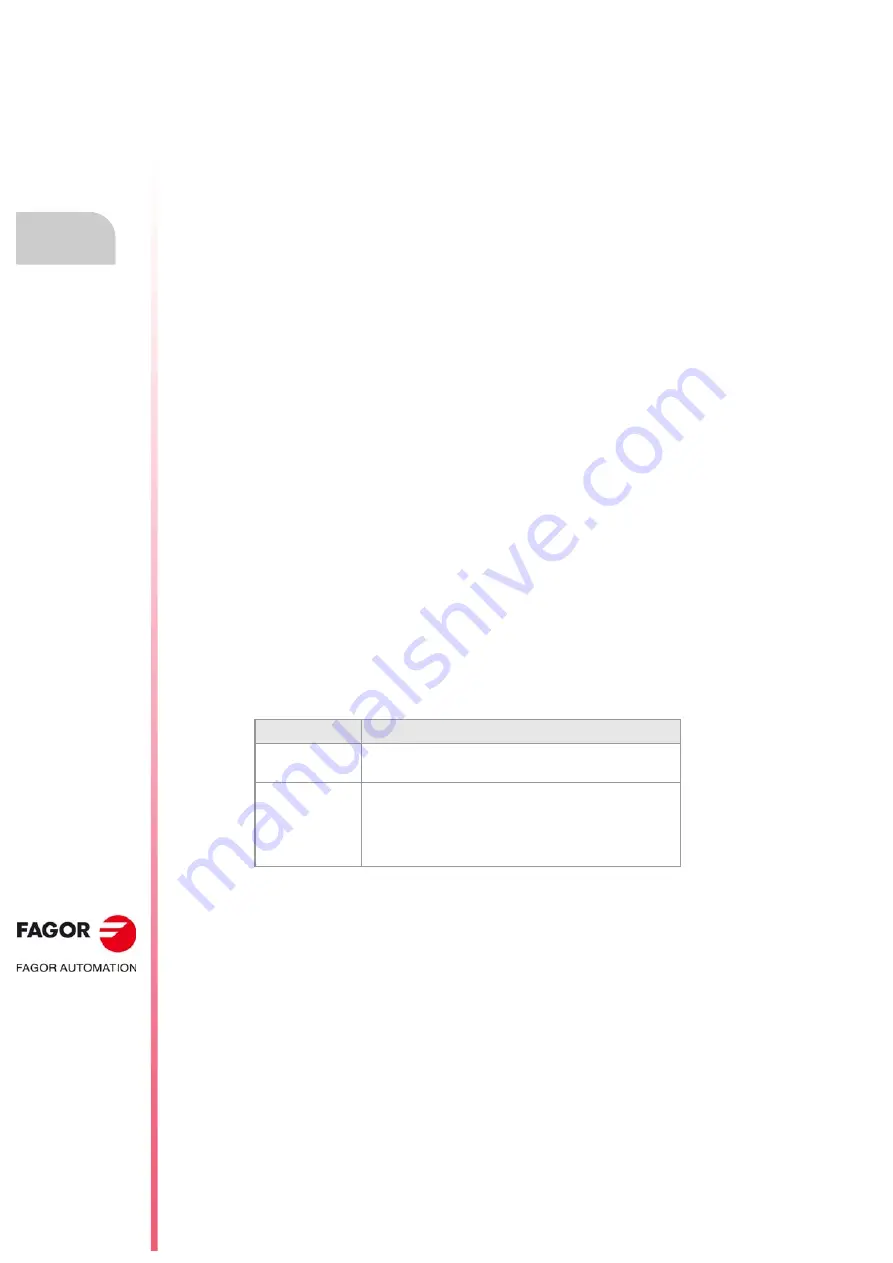

SWTG0FEED

Meaning.

Yes

Movements in G0 are carried out at a rapid feedrate

(parameter G00FEED).

No

The cut is made at a constant feedrate (with the feedrate of

the previous G1/G2/G3), without accelerating in the

sections in G0. This option makes it possible to prevent

possible problems with machine frequency excitation, thus

producing better quality precision and surface cuts.

Содержание CNC 8060

Страница 1: ...Ref 1709 8060 8065 CNC Installation manual...

Страница 10: ...BLANK PAGE 10...

Страница 14: ...BLANK PAGE 14...

Страница 20: ...BLANK PAGE 20...

Страница 32: ...BLANK PAGE 32...

Страница 36: ...BLANK PAGE 36...

Страница 38: ...BLANK PAGE 38...

Страница 40: ...BLANK PAGE 40...

Страница 41: ...PART 1 INSTALLATION MANUAL...

Страница 42: ...BLANK PAGE 42...

Страница 58: ...Installation manual CNC 8060 CNC 8065 1 SOFTWARE INSTALLATION Software configuration 58 REF 1709...

Страница 340: ...Installation manual CNC 8060 CNC 8065 3 INTRODUCTION TO THE PLC Operation of a counter 340 REF 1709...

Страница 448: ...Installation manual CNC 8060 CNC 8065 6 LOGIC CNC INPUTS AND OUTPUTS Keystroke modifiable signals 448 REF 1709...

Страница 532: ...Installation manual CNC 8060 CNC 8065 9 CNC VARIABLES 532 REF 1709...

Страница 533: ...PART 2 CONCEPTS...

Страница 534: ...BLANK PAGE 534...

Страница 548: ...Installation manual CNC 8060 CNC 8065 10 GENERAL SETUP Configuration examples 548 REF 1709...

Страница 574: ...Installation manual CNC 8060 CNC 8065 11 CONFIGURING AN AXIS Home search 574 REF 1709 X Z H OM OW ZMH ZMW XMH...

Страница 598: ...Installation manual CNC 8060 CNC 8065 12 VOLUMETRIC COMPENSATION Error messages cause and solution 598 REF 1709...

Страница 644: ...Installation manual CNC 8060 CNC 8065 14 SUBROUTINES Assistance for subroutines 644 REF 1709...

Страница 668: ...Installation manual CNC 8060 CNC 8065 15 HARDWARE Configure the PT100 inputs 668 REF 1709...

Страница 697: ...Installation manual CNC 8060 CNC 8065 697 User notes REF 1709...