Engström Carestation

7-2

08/07 1505-1018-000

7.1 Troubleshooting Checkout Failures

Note:

If the Automated Checkout (Section 3.2) results in failures, refer to the

following sections to troubleshoot a specific failure. Use EC Service

Application PC based (Section 8.5) while running all tests .

To file a quality report or request technical assistance regarding a checkout

failure, create and include a Checkout log using the EC Service Application.

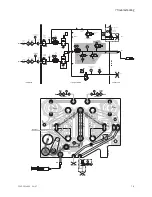

7.1.1 Paw transducer

check

The Paw Transducer Check can indicate a failure from four conditions:

1. Inspiratory Pressure Sensor Zero Failure:

With the Inspiratory Pressure Zero Valve actuated, raw counts from the

Inspiratory Pressure Sensor must be between 631 and 968; if not, test

results indicate

Fail

and the

Pinsp sensor out of range

message is

displayed.

• Use EC Service Application PC based (Section 8.5) to facilitate problem

isolation.

• Ensure proper connections.

• Remove the Inspiratory Pressure Zero valve. If the Inspiratory Pressure

Sensor values are between 631 and 968 counts, replace the Zero Valve.

• Replace the Inspiratory Pressure Sensor Board.

• Replace the Vent Control board (VCB).

2. Expiratory Pressure Sensor Zero Failure:

With the Expiratory Pressure Zero Valve actuated, raw counts from the

Expiratory Pressure Sensor must be between 631 and 968; if not, test

results indicate

Fail

and

Pexp sensor out of range

message is displayed.

• Use EC Service Application PC based (Section 8.5) to facilitate problem

isolation.

• Ensure proper connections.

• Remove the Expiratory Pressure Zero valve. If the Inspiratory Pressure

Sensor values are between 631 and 968 counts, replace the Zero Valve.

• Replace the Expiratory Pressure Sensor board.

• Replace the Vent Monitor board (VMB).

3. Cannot achieve 34 cmH

2

O pressure:

The Air (O

2

) flow valve is set to approximately 10 lpm and the test is

initiated if 34 cmH2O pressure is not achieved; test results indicate

Fail

but no alarm message is displayed.

• Use EC Service Application PC based (Section 8.5) to facilitate problem

isolation.

• Ensure supply gas is connected.

• Continue with other tests. If a significant leak is indicated during the Low

Pressure Leak test, repair the leak then repeat this check.

• Check respective Flow Control Valve for proper operation.

Содержание Engstrom Carestation

Страница 1: ...Engström Carestation Technical Reference Manual ...

Страница 12: ...Engström Carestation x 08 07 1505 1018 000 ...

Страница 52: ...Engström Carestation 2 26 08 07 1505 1018 000 ...

Страница 100: ...Engström Carestation 5 26 08 07 1505 1018 000 ...

Страница 124: ...Engström Carestation 7 16 08 07 1505 1018 000 ...

Страница 188: ...Engström Carestation 8 26 08 07 1505 1018 000 ...

Страница 225: ...ERROR undefined OFFENDING COMMAND STACK ...