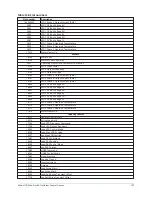

Table 143: Safety shutdown messages

Message

Description

DISCHARGE #1 – HIGH

PRESSURE CONTACTS OPEN

The contacts of the electro-mechanical high pressure switch (HP1, located in the discharge

line of compressor #1) have opened because it detected a pressure >180.0 psig. The contacts

will automatically close when the discharge pressure decreases to < 120.0 psig and the

Operator presses the Clear Faults button.

DISCHARGE #2 – HIGH

PRESSURE CONTACTS OPEN

The contacts of the electro-mechanical high pressure switch (HP2, located in the discharge

line of compressor #2) have opened because it detected a pressure >180.0 psig. The contacts

will automatically close when the discharge pressure decreases to < 120.0 psig and the

Operator presses the Clear Faults button.

DISCHARGE #1 – HIGH

TEMPERATURE

The chiller (both compressors) has shutdown because the discharge temperature of

compressor #1, as sensed by thermistor RT2, has increased to >220.0 ºF. The chiller can be

started after the temperature decreases to <220.0 ºF and the Operator presses the Clear

Faults button.

If compressor #1 is locked out using the Lockout key on the Capacity Compressor Cycling

Screen, this fault does not cause compressor #2 to shutdown or prevent it from starting.

When this fault occurs on a locked-out compressor, it is displayed as a warning. This allows

the user to know that a fault exists on the locked-out compressor. The condition must be

corrected prior to the lockout being removed from the compressor. If it is not, the warning

condition will revert back to a shutdown as soon as the lockout is removed and will cause the

chiller to trip.

DISCHARGE #2 – HIGH

TEMPERATURE

The chiller (both compressors) has shutdown because the discharge temperature of

compressor #2, as sensed by thermistor RT8, has increased to >220.0 ºF. The chiller can be

started after the temperature decreases to <220.0 ºF and the Operator presses the Clear

Faults button.

If compressor #2 is locked out using the Lockout key on the Capacity Compressor Cycling

Screen, this fault does not cause compressor #1 to shutdown or prevent it from starting.

When this fault occurs on a locked-out compressor, it is displayed as a warning. This allows

the user to know that a fault exists on the locked-out compressor. The condition must be

corrected prior to the lockout being removed from the compressor. If it is not, the warning

condition will revert back to a shutdown as soon as the lockout is removed and will cause the

chiller to trip.

DISCHARGE #1 – LOW

TEMPERATURE

The chiller (both compressors) has shutdown because the discharge temperature of

compressor #1, as sensed by thermistor RT2, has decreased to <30.0 ºF. The chiller can be

started after the temperature increases to >30.0ºF and the Operator presses the Clear Faults

button.

If compressor #1 is locked out using the Lockout key on the Capacity Compressor Cycling

Screen, this fault does not cause compressor #2 to shutdown or prevent it from starting.

When this fault occurs on a locked-out compressor, it is displayed as a warning. This allows

the user to know that a fault exists on the locked-out compressor. The condition must be

corrected prior to the lockout being removed from the compressor. If it is not, the warning

condition will revert back to a shutdown as soon as the lockout is removed and will cause the

chiller to trip.

DISCHARGE #2 – LOW

TEMPERATURE

The chiller (both compressors) has shutdown because the discharge temperature of

compressor #2, as sensed by thermistor RT8, has decreased to <30.0 ºF. The chiller can be

started after the temperature increases to >30.0ºF and the Operator presses the Clear Faults

button.

If compressor #2 is locked-out using the Lockout key on the Capacity Compressor Cycling

Screen, this fault does not cause compressor #1 to shutdown or prevent it from starting.

When this fault occurs on a locked-out compressor, it is displayed as a warning. This allows

the user to know that a fault exists on the locked-out compressor. The condition must be

corrected prior to the lockout being removed from the compressor. If it is not, the warning

condition will revert back to a shutdown as soon as the lockout is removed and will cause the

chiller to trip.

141

Model YD Mod D with OptiView Control Center

Summary of Contents for YD Mod D

Page 2: ...2 Model YD Mod D with OptiView Control Center...

Page 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Page 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Page 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Page 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Page 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Page 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Page 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Page 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Page 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Page 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Page 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Page 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Page 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Page 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Page 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Page 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...