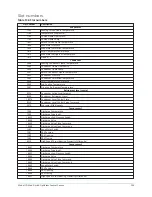

Table 142: Cycling shutdown messages

Message

Description

Motor Controller #2 –

Loss Of Current

The chiller (both compressors 0 shutdown because compressor #2 motor current has

decreased to < 10% FLA for 25 continuous seconds while it was running. This could be caused

by the starter de-energizing or a defect in the motor current detection circuitry to the control

center. The motor current value is provided by CM-2 board 2 to the microboard. The chiller

will automatically restart at the completion of coastdown.

Motor Controller #1 –

Power Fault

A motor controller protection device has shutdown the chiller (both compressors). Normally

closed contacts of locally installed external motor protection devices (connected between

TB6-15 and TB6-53) and the normally closed CM contacts of CM-2 Board 1 (connected

between TB6-53 and TB6-16) form a safety circuit in series with the starter run signal. If any

of these contacts open and reclose in less than 3 seconds, this shutdown is initiated. The

CM-2 board opens its contacts and recloses them in less than 3 seconds when it detects a

motor current power fault condition on motor #1. A power fault condition occurs when the

motor current drops below 10% FLA. This protects against potential compressor damage

due to rapid opening and reclosure of the motor starter. When it detects this condition,

the power fault LED on the CM-2 board lights and the board’s CM contacts open and

automatically reclose in less than 3 seconds to initiate the shutdown. The LED will remain

lit until the reset button on the CM-2 board is pressed. The chiller will automatically restart

when at the completion of coastdown.

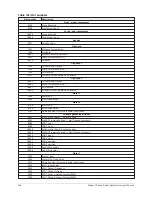

Motor Controller #2 –

Power Fault

A motor controller protection device has shutdown the chiller (both compressors). Normally

closed contacts of locally installed external motor protection devices (connected between

TB6-15 and TB6-54) and the normally closed CM contacts of CM-2 Board 2 (connected

between TB6-54 and TB6-82) form a safety circuit in series with the starter run signal. If any

of these contacts open and reclose in less than 3 seconds, this shutdown is initiated. The

CM-2 board opens its contacts and recloses them in less than 3 seconds when it detects a

motor current power fault condition on motor 2. A power fault condition occurs when the

motor current drops below 10% FLA. This protects against potential compressor damage

due to rapid opening and reclosure of the motor starter. When it detects this condition,

the power fault LED on the CM-2 board lights and the board’s CM contacts open and

automatically reclose in less than 3 seconds to initiate the shutdown. The LED will remain

lit until the reset button on the CM-2 board is pressed. The chiller will automatically restart

when at the completion of coastdown.

Leaving Chilled Liquid

– Low Temperature

The chiller (both compressors) has shutdown because the leaving

Chilled Liquid

Temperature

has decreased to the programmed

Shutdown Temperature

setpoint. If the

chiller is running when this occurs, the pre-rotation vanes on the running compressors are

driven fully closed prior to shutting down the chiller. The chiller will automatically restart

when the temperature increases to the programmed

Restart Temperature

setpoint.

Control Panel –

Schedule

The programmed

Daily Schedule

setpoint has shutdown the chiller (both compressors).

If the chiller is running when this occurs, the pre-rotation vanes on the running compressors

are driven fully closed prior to shutting down the chiller. The chiller will automatically restart

at the next scheduled start time.

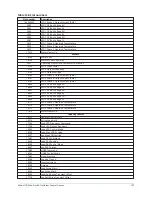

Oil Pump #1 – Drive

Contacts Open

The oil pump variable speed drive for compressor 1 has shutdown the chiller (both

compressors). It initiates this shutdown by opening its status contacts connected to the I/O

Board TB3-70. The drive initiates a shutdown anytime its internal protection circuits will not

permit the Drive to run. The contacts remain open until its internal protection circuits are

satisfied and any applicable manual resets are performed. Refer to

YORK Variable Speed Oil

Pump Drive Service Manual 160.52-M2

.

If compressor 1 is locked out using the

Lockout

key on the Capacity compressor cycling

screen, this fault does not cause compressor 2 to shutdown or prevent it from starting.

When this fault occurs on a locked-out compressor, it is displayed as a warning. This allows

the user to know that a fault exists on the locked-out compressor. The condition must be

corrected prior to the lockout being removed from the compressor. If it is not, the warning

condition will revert back to a shutdown as soon as the lockout is removed and will cause the

chiller to trip.

137

Model YD Mod D with OptiView Control Center

Summary of Contents for YD Mod D

Page 2: ...2 Model YD Mod D with OptiView Control Center...

Page 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Page 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Page 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Page 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Page 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Page 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Page 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Page 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Page 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Page 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Page 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Page 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Page 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Page 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Page 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Page 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...