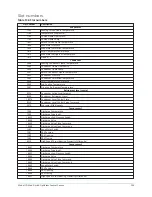

Cycling shutdown messages

Table 142: Cycling shutdown messages

Message

Description

Multiunit Cycling –

Contacts Open

The multiunit cycling contacts connected to I/O Board TB4-9, have opened to initiate a

cycling shutdown on the chiller (both compressors). If the chiller is running when this occurs,

the pre-rotation vanes on the running compressors are driven fully closed prior to shutting

down the chiller. The chiller will automatically restart when the contacts close.

System Cycling #1 –

Contacts Open

The remote/local cycling contacts connected to the I/O Board TB4-13 have opened to initiate

a cycling shutdown on the chiller, on both compressors. If the chiller is running when this

occurs, the pre-rotation vanes on the running compressors are driven fully closed prior to

shutting down the chiller. The chiller will automatically restart when the contacts close.

System Cycling #2

Contacts Open

The remote/local cycling contacts connected to the I/O Board TB4-95 have opened to initiate

a cycling shutdown on the chiller, on both compressors. If the chiller is running when this

occurs, the pre-rotation vanes on the running compressors are driven fully closed prior to

shutting down the chiller. The chiller will automatically restart when the contacts close.

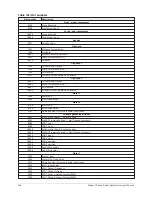

Motor Controller #1 –

Contacts Open

A motor controller protection device for compressor 1 has initiated a shutdown (both

compressors). Normally closed contacts of locally installed external motor protection devices

(connected between TB6-15 and TB6-53) and the normally closed CM contacts of CM-2 Board

1 (connected between TB6-53 and TB6-16) form a safety circuit in series with the starter run

signal. If any of these contacts open and remain open for at least 3 seconds, this shutdown

is initiated. The CM-2 board opens its contacts when it detects a motor current overload

condition on motor 1. When it detects this condition, the overload LED on the CM-2 board

lights and the board’s CM contacts open to initiate the shutdown. The LED will remain lit and

the contacts will remain open until the reset button on the CM-2 board is pressed. The chiller

will automatically restart when the contacts close.

If compressor 1 is locked-out using the

Lockout

key on the Capacity compressor cycling

screen, this fault does not cause compressor 2 to shutdown or prevent it from starting.

When this fault occurs on a locked-out compressor, it is displayed as a warning. This allows

the user to know that a fault exists on the locked-out compressor. The condition must be

corrected prior to the lockout being removed from the compressor. If it is not, the warning

condition will revert back to a shutdown as soon as the lockout is removed and will cause the

chiller to trip.

Motor Controller #2 –

Contacts Open

A motor controller protection device for compressor 2 has initiated a shutdown (both

compressors). Normally closed contacts of locally installed external motor protection devices

(connected between TB6-15 and TB6-54) and the normally closed CM contacts of CM-2 Board

2 (connected between TB6-54 and TB6-82) form a safety circuit in series with the starter run

signal. If any of these contacts open and remain open for at least 3 seconds, this shutdown

is initiated. The CM-2 board opens its contacts when it detects a motor current overload

condition on motor 2. When it detects this condition, the overload LED on the CM-2 board

lights and the board’s CM contacts open to initiate the shutdown. The LED will remain lit and

the contacts will remain open until the reset button on the CM-2 board is pressed. The chiller

will automatically restart when the contacts close.

If compressor 2 is locked-out using the

Lockout

key on the Capacity compressor cycling

screen, this fault does not cause compressor 1 to shutdown or prevent it from starting.

When this fault occurs on a locked-out compressor, it is displayed as a warning. This allows

the user to know that a fault exists on the locked-out compressor. The condition must be

corrected prior to the lockout being removed from the compressor. If it is not, the warning

condition will revert back to a shutdown as soon as the lockout is removed and will cause the

chiller to trip.

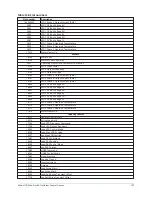

Motor Controller #1 –

Loss Of Current

The chiller (both compressors) shutdown because the compressor 1 motor current has

decreased to < 10% FLA for 25 continuous seconds while it was running. This could be caused

by the starter de-energizing or a defect in the motor current detection circuitry to the control

center. The motor current value is provided by CM-2 board 1 to the Microboard. The chiller

will automatically restart at the completion of coastdown.

Model YD Mod D with OptiView Control Center

136

Summary of Contents for YD Mod D

Page 2: ...2 Model YD Mod D with OptiView Control Center...

Page 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Page 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Page 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Page 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Page 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Page 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Page 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Page 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Page 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Page 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Page 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Page 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Page 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Page 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Page 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Page 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...