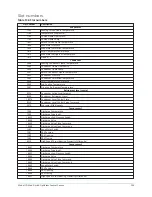

Warning messages

Table 140: Warning messages

Message

Description

Warning – Condenser Or

Evaporator XDCR Error

The evaporator pressure transducer is indicating a higher pressure than the condenser

pressure transducer after the chiller has been running for 10 minutes. This is indicative

of a condenser or evaporator transducer failure. This message will be displayed until the

condition clears and the

Warning Reset

key is pressed in operator (or higher) access level.

Condition not checked in brine mode.

Warning – Condenser Or

VGD #1 Sensor Failure

The difference between compressor 1 stall pressure transducer output and the condenser

pressure transducer output has exceeded 0.28 VDC for 3 continuous minutes while

compressor 1 was running. This feature verifies the operation of compressor 1 stall

transducer and the condenser transducer. Since both transducers are measuring essentially

the same pressure, both outputs should be within the specified tolerance. This message

must be manually cleared. It will be displayed until the transducer outputs are within the

acceptable range of each other and the

Warning Reset

key in service access level.

While this message is displayed, the variable geometry diffuser (VGD) of both compressors

are driven to the full open position (100%) and held there until this warning is manually is

cleared. When cleared, the VGD of both compressors return to normal operation.

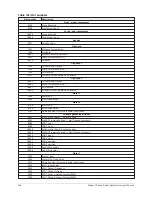

Warning – Condenser Or

VGD #2 Sensor Failure

The difference between compressor 2 stall pressure transducer output and the condenser

pressure transducer output has exceeded 0.28 VDC for 3 continuous minutes while

compressor 2 was running. This feature verifies the operation of the compressor 2 stall

transducer and the condenser transducer. Since both transducers are measuring essentially

the same pressure, both outputs should be within the specified tolerance. This message

must be manually cleared. It will be displayed until the transducer outputs are within the

acceptable range of each other and the

Warning Reset

key in service access level.

While this message is displayed, the variable geometry diffuser (VGD) of both compressors

are driven to the full open position (100%) and held there until this warning is manually is

cleared. When cleared, the VGD of both compressors return to normal operation.

Warning – Conditions

Override VGD #1

An extreme stall condition has been detected in compressor 1 while it was running. An

extreme stall condition exists when the stall detector voltage (output of the stall detector

board) exceeds twice the

High Limit

setpoint for the duration programmed in the

Extreme Stall Duration

setpoint (10 to 20 minutes). While this message is displayed,

compressor #1 variable geometry diffuser is driven to the full open (100%) position and

held there until the message is manually cleared. This protects the VGD ring from possible

damage from an extreme stall condition. This message can be cleared after the stall detector

voltage returns to less than two times the

High Limit

setpoint and the

Warning Reset

key

is pressed in service access level.

The extreme stall condition is not checked under the following conditions:

•

While the VGD is in manual control mode

•

While the VGD is fully closed with position at 0% - VGD limit switch closed

•

While the pre-rotation vanes position is greater than the

PRV VGD Inhibit

setpoint

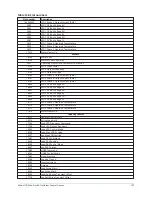

Warning – Conditions

Override VGD #2

An extreme stall condition has been detected in compressor 2 while it was running. An

extreme stall condition exists when the stall detector voltage (output of the stall detector

board) exceeds twice the

High Limit

setpoint for the duration programmed in the

Extreme Stall Duration

setpoint (10 to 20 minutes). While this message is displayed,

compressor 2 variable geometry diffuser (VGD) is driven to the full open (100%) position and

held there until the message is manually cleared. This protects the VGD ring from possible

damage from an extreme stall condition. This message can be cleared after the stall detector

voltage returns to less than two times the

High Limit

setpoint and the

Warning Reset

key

is pressed in service access level.

The extreme stall condition is not checked under the following conditions:

•

While the VGD is in manual control mode

•

While the VGD is fully closed with position at 0% - VGD limit switch closed

•

While the pre-rotation vanes position is greater than the

PRV VGD inhibit

setpoint

Model YD Mod D with OptiView Control Center

132

Summary of Contents for YD Mod D

Page 2: ...2 Model YD Mod D with OptiView Control Center...

Page 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Page 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Page 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Page 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Page 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Page 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Page 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Page 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Page 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Page 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Page 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Page 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Page 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Page 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Page 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Page 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...