POWR

Power unit

5-43

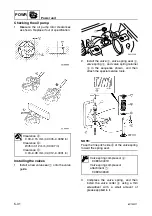

6C13G11

3.

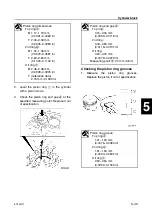

Put a piece of Plastigauge (PG-1) onto

the crankpin, parallel to the crankshaft.

NOTE:

Be sure not to put the Plastigauge (PG-1)

over the oil hole in the crankpin of the crank-

shaft.

4.

Install the connecting rod onto the crank-

pin

3

.

NOTE:

Make sure that the marks

b

of the connect-

ing rod face toward the flywheel magnet end

of the crankshaft.

5.

Tighten the connecting rod bolts to the

specified torques in two stages.

NOTE:

Do not turn the connecting rod until the

crankpin oil clearance measurement has

been completed.

6.

Remove the connecting rod cap and

measure the width of the compressed

Plastigauge (PG-1) on each crankpin.

Replace the connecting rod bearing if out

of specification.

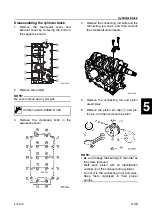

Selecting the connecting rod bearing

1.

When replacing the connecting rod bear-

ing, select the suitable bearing as fol-

lows.

2.

Check the crankpin mark on the crank-

shaft

1

and the connecting rod mark or

painted color

a

on the connecting rod.

T

R

.

.

Connecting rod cap bolt:

1st: 6 N·m (0.6 kgf·m, 4.4 ft·lb)

2nd: 17 N·m (1.7 kgf·m, 12.5 ft·lb)

Crankpin oil clearance:

0.016–0.040 mm

(0.0006–0.0016 in)

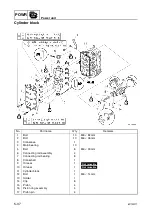

Summary of Contents for F50F

Page 1: ...F50F FT50G F60C FT60D SERVICE MANUAL 6C1 28197 3G 11 290551 ...

Page 4: ......

Page 48: ...SPEC Specifications 2 25 6C13G11 MEMO ...

Page 190: ...LOWR Lower unit 6 47 6C13G11 Shimming FT50 FT60 6 ...

Page 195: ...6C13G11 6 52 1 2 3 4 5 6 7 8 9 MEMO Backlash FT50 FT60 ...

Page 221: ...6C13G11 7 24 1 2 3 4 5 6 7 8 9 Steering arm ...

Page 249: ...6C13G11 7 52 1 2 3 4 5 6 7 8 9 MEMO Power trim and tilt electrical system ...

Page 272: ...ELEC Electrical systems 8 21 6C13G11 MEMO ...

Page 301: ...6C13G11 i 5 1 2 3 4 5 6 7 8 9 Index MEMO ...

Page 303: ......

Page 304: ...YAMAHA MOTOR CO LTD Printed in the Netherlands Jul 2004 1 2 1 CR E_2 ...