6C13G11

5-26

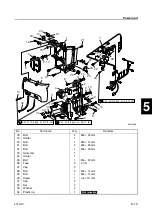

1

2

3

4

5

6

7

8

9

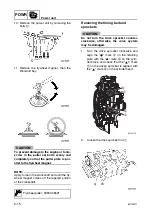

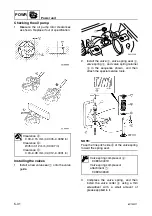

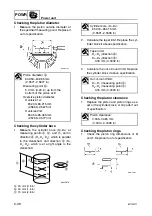

NOTE:

Apply engine oil to the surface of the new

valve guide.

3.

Insert the special service tool into the

valve guide

2

, and then ream the valve

guide.

NOTE:

• Turn the valve guide reamer clockwise to

ream the valve guide.

• Do not turn the reamer counterclockwise

when removing the reamer.

4.

Measure the valve guide inside diameter.

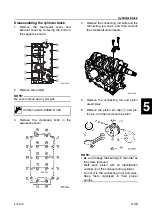

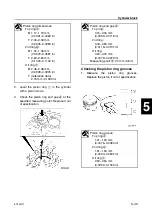

Checking the valve seat

1.

Eliminate carbon deposits from the valve

with a scraper.

2.

Apply a thin, even layer of Mechanic’s

blueing dye (Dykem) onto the valve seat.

3.

Lap the valve slowly on the valve seat

with a valve lapper (commercially avail-

able) as shown.

Valve guide remover/installer:

90890-06801

Valve guide installer: 90890-06810

Valve guide position

a

:

16.5

±

0.2 mm (0.650

±

0.008 in)

Valve guide reamer: 90890-06804

Valve guide inside diameter:

Intake and exhaust:

5.500–5.512 mm

(0.2165–0.2170 in)

Summary of Contents for F50F

Page 1: ...F50F FT50G F60C FT60D SERVICE MANUAL 6C1 28197 3G 11 290551 ...

Page 4: ......

Page 48: ...SPEC Specifications 2 25 6C13G11 MEMO ...

Page 190: ...LOWR Lower unit 6 47 6C13G11 Shimming FT50 FT60 6 ...

Page 195: ...6C13G11 6 52 1 2 3 4 5 6 7 8 9 MEMO Backlash FT50 FT60 ...

Page 221: ...6C13G11 7 24 1 2 3 4 5 6 7 8 9 Steering arm ...

Page 249: ...6C13G11 7 52 1 2 3 4 5 6 7 8 9 MEMO Power trim and tilt electrical system ...

Page 272: ...ELEC Electrical systems 8 21 6C13G11 MEMO ...

Page 301: ...6C13G11 i 5 1 2 3 4 5 6 7 8 9 Index MEMO ...

Page 303: ......

Page 304: ...YAMAHA MOTOR CO LTD Printed in the Netherlands Jul 2004 1 2 1 CR E_2 ...